Preparation method and application of zinc cobaltate/nickel oxide core-shell nanowire array

A nanowire array and zinc cobalt oxide technology, which is applied in the field of lithium-ion batteries, can solve the problems of unreported zinc cobalt oxide/nickel oxide composite materials, reduce the volumetric energy density of materials, and complicate nano-array methods, and achieve mesoscopic structure preservation. Intact, easy to achieve industrialization, good cycle performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

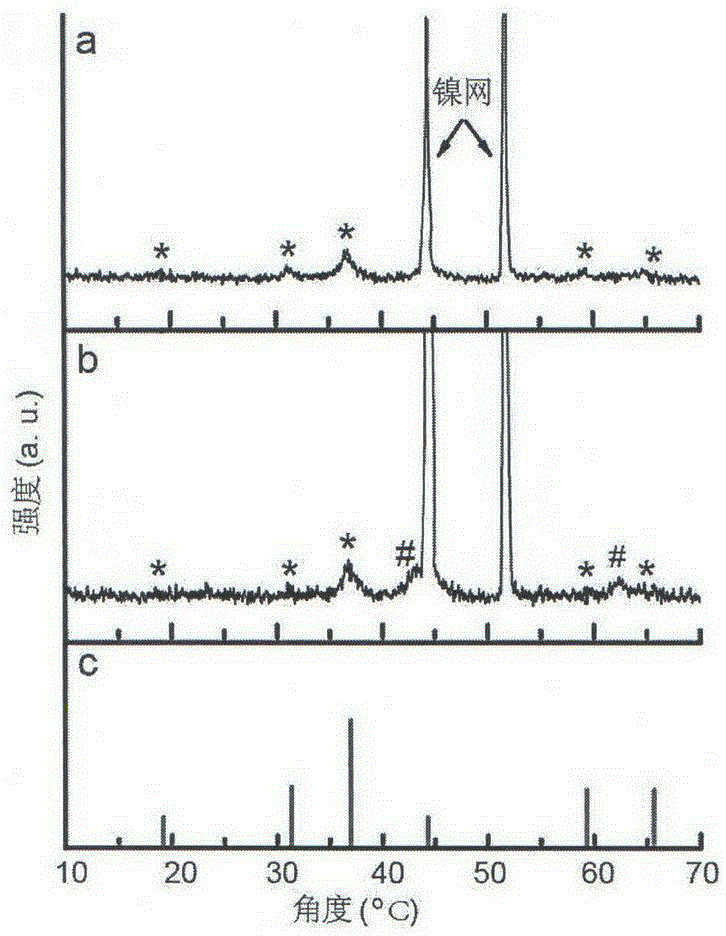

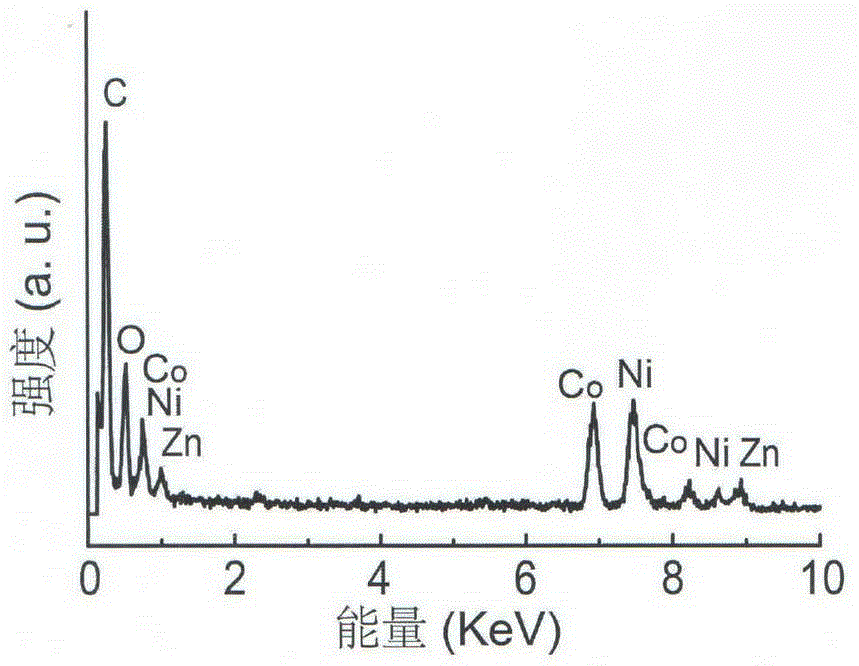

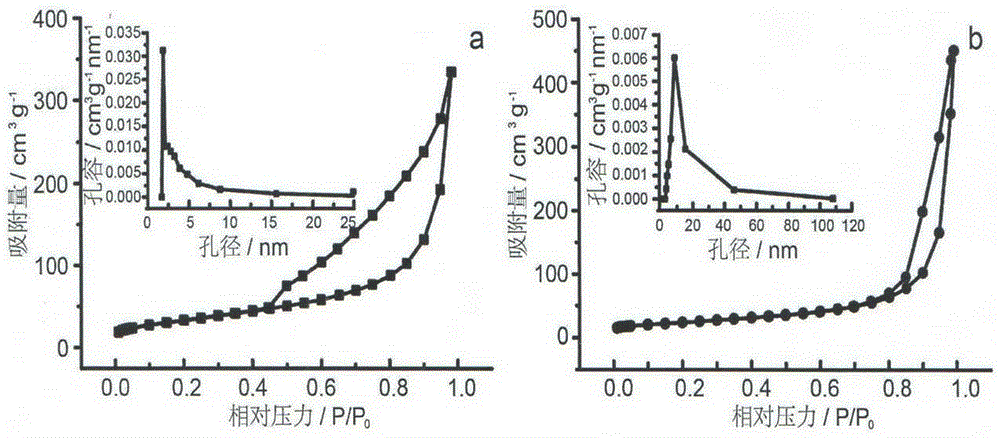

[0029] Example 1 Preparation of zinc cobaltate / nickel oxide core-shell nanowire arrays:

[0030] a. At room temperature, the soluble zinc salt Zn(NO 3 ) 2 , soluble cobalt salt Co(NO 3 ) 2 , ammonium fluoride and urea in a molar ratio of 1:2:1:5 were added to 25mL water and mixed thoroughly for 10min to obtain a uniform solution. In the reaction kettle, the temperature was raised from 30°C to 120°C, the heating rate was 1°C / min, and the reaction was carried out for 5 hours to obtain a foamed nickel substrate with light green nanowire arrays grown on it;

[0031] b. The substrate grown with cyan nanowire arrays in step a is heated from 30°C to 400°C at a heating rate of 1°C / min, and calcined for 1 hour to obtain a substrate grown with dark brown zinc cobaltate nanowire arrays;

[0032] c. Place the substrate with dark brown zinc cobaltate nanowire arrays grown in step b in a mixed solution with a volume ratio of nickel sulfate: potassium peroxodisulfate: ammonia water = 5: ...

Embodiment 2

[0035] Example 2 Preparation of zinc cobaltate / nickel oxide core-shell nanowire arrays:

[0036] a. At room temperature, the soluble zinc salt Zn(NO 3 ) 2 , soluble cobalt salt Co(CH 2 CH 3 ) 2 , ammonium fluoride and urea in a molar ratio of 1:2:1:6 were added to 25mL water and mixed thoroughly for 10 minutes to obtain a homogeneous solution. Then, the clean nickel substrate was put into a 40mL reaction kettle, and the homogeneous solution was added to In the reaction kettle, the temperature was raised from 30°C to 120°C, the heating rate was 2°C / min, and the reaction was carried out for 8 hours to obtain a nickel sheet substrate with a light green nanowire array grown on it;

[0037] b. Heat up the nickel sheet substrate with cyan nanowire arrays grown in step a at a temperature of 30° C. to 400° C. at a heating rate of 1° C. / min, and bake for 2 hours to obtain a substrate grown with dark brown zinc cobaltate nanowire arrays ;

[0038] c. Place the substrate with dark ...

Embodiment 3

[0041] Example 3 Preparation of zinc cobaltate / nickel oxide core-shell nanowire arrays:

[0042] a. At room temperature, the soluble zinc salt Zn(CH 2 CH 3 ) 2 , soluble cobalt salt CoCl 2 , ammonium fluoride and urea in a molar ratio of 1:2:1.2:6 were added to 25mL of water and mixed thoroughly for 10min to obtain a homogeneous solution. Add it into the reaction kettle, raise the temperature from 30°C to 130°C, the heating rate is 3°C / min, and react for 6 hours to obtain a carbon cloth substrate with light green nanowire arrays grown on it;

[0043] b. Heat up the carbon cloth substrate with cyan nanowire arrays grown in step a at a temperature of 30°C to 400°C at a heating rate of 1°C / min, and bake for 2 hours to obtain a substrate with dark brown zinc cobaltate nanowire arrays grown on it ;

[0044] c. Place the substrate with dark brown zinc cobaltate nanowire arrays grown in step b in a mixed solution with a volume ratio of nickel sulfate: potassium peroxodisulfate: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com