D-galactose/benzaldehyde nitrogen mustard/N-(2-hydroxypropyl) methacrylamide copolymer as well as preparation and application thereof

A technology of methacrylamide copolymer and methacrylamide, applied in the field of polymer chemistry, can solve the problems of inconvenient drug administration, poor water solubility of benzaldehyde mustard, toxic side effects and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) compound Preparation: take benzaldehyde nitrogen mustard (1.0 g, 5.6 mmol, 1.0 equiv.), dissolve in 75 mL tetrahydrofuran, add 15-20 g molecular sieves, and add p-toluenesulfonic acid (0.13 g, 0.75 mmol, 0.13 equiv.), 1,1,1-trimethylolethane (1.45g, 16mmol, 3.0equiv.), reacted in an ice-water bath for 12-15 h; followed the reaction by thin-layer chromatography, and the benzaldehyde nitrogen After the mustard reaction is complete, add ammonia water to neutralize p-toluenesulfonic acid to pH = 7-8, filter out molecular sieves, concentrate the filtrate, dilute with dichloromethane, wash three times with phosphate buffer solution with pH = 8, and wash with anhydrous Sodium sulfate was dried for 12 hours, separated by silica gel column chromatography (ethyl acetate / petroleum ether = 1 / 101 (v / v)), the product components were collected, and the solvent was evaporated to obtain the compound (1.08g). Yield (78%).

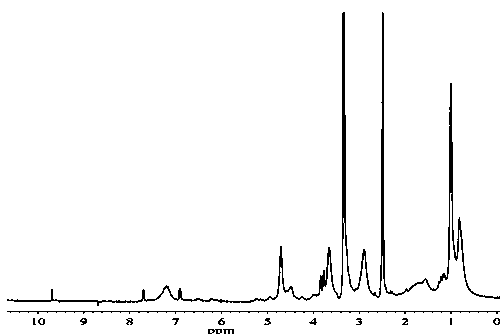

[0051] 1 H NMR (400MHz, CDCl 3 ): δ7.61 (d, J = 7.2...

Embodiment 2

[0063] compound , , , , The preparation is with embodiment 1.

[0064] Preparation of copolymer: Weigh HPMA (0.159 g, 1.11 mmol, 82 mol%) into a Shleck bottle, heat to dissolve with 0.5 mL of DMSO, then add 0.5 mL of acetone; weigh the compound (0.038 g, 0.09 mmol, 7 mol%) and compound (0.023 g, 0.09 mmol, 7 mol%) was added to the Shleck bottle, stirred until dissolved, and when cooled to room temperature, 0.018 g (8%, wt) of azoisobutyronitrile (AIBN) was added, vacuumized and nitrogen cycled 3 to 5 times, keep the temperature at about 55°C after sealing, and react for 24 hours. Precipitate with a mixture of acetone and ether (volume ratio 7:3), filter and dissolve the precipitate with 1ml of anhydrous methanol, centrifuge with an ultrafiltration concentration centrifuge tube with a molecular weight of 3000, remove small molecules, and obtain 0.153g of polymer , yield 70%.

[0065] m n =2.4×10 4 , M w / M n =1.16. 1 H-NMR (400 MHz, DMSO, δ, ppm): δ 7.26 ...

Embodiment 3

[0067] compound , , , , The preparation is with embodiment 1.

[0068] Preparation of copolymer: Weigh HPMA (0.159 g, 1.11 mmol, 80 mol%) into a Shleck bottle, heat to dissolve with 0.5 mL of DMSO, then add 0.5 mL of acetone; weigh the compound (0.057g, 0.14 mmol, 10 mol%) and compound 5 (0.034 g, 0.14 mmol, 10 mol%) were added to the Shleck bottle, stirred until dissolved, and 0.025 g (10%, wt) di Nitrogen and isobutyronitrile (AIBN), vacuumize and nitrogen cycle 3 to 5 times, keep the temperature at about 55°C after sealing, and react for 24 hours. Precipitate with a mixture of acetone and ether (volume ratio 7:3), filter and dissolve the precipitate with 1ml of anhydrous methanol, centrifuge with an ultrafiltration concentration centrifuge tube with a molecular weight of 3000, remove small molecules, and obtain 0.16 g of polymer , yield 64%.

[0069] m n =2.6×104 , M w / M n =1.23. 1 H-NMR (400 MHz, DMSO, δ, ppm): δ 7.26 (–CHC 6 H 2 h 2 N(CH 2 CH 2 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com