Spectrum locally-modified hot color nano-composite powder and preparation method thereof

A nanocomposite powder and localized technology, applied in the direction of coating, etc., to achieve the effects of low cost, expanded applicability, improved stability and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

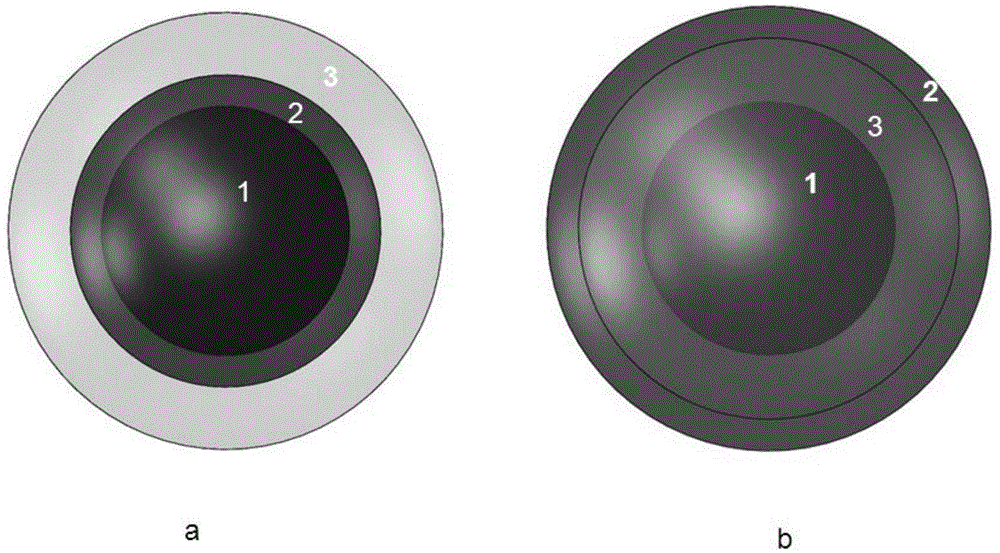

Image

Examples

preparation example Construction

[0030] The dispersing aid used in the above-mentioned preparation process is polyvinyl alcohol, polyvinylpyrrolidone, organic silicon surfactant, sodium dodecylsulfonate, polyacrylic acid, silane coupling agent, titanate coupling agent or well-known in the industry One or more of the dispersing aids. Dispersion aids are mainly used to reduce the surface tension of the solution and improve the wetting of the solvent on the surface of the powder, thereby improving the dispersion effect. The amount of the dispersing aid added in steps (1) and (3) is 0.02-2% by weight of the dispersion medium; preferably 0.05-1% by weight.

[0031] The raw materials and reagents used in the above method can be purchased from the market or synthesized by traditional chemical transformation. Unless otherwise defined or stated, all professional and scientific terms used herein have the same meanings as those familiar to those skilled in the art. In addition, any methods and materials similar or equ...

Embodiment 1

[0034] First put 2g of VO with a particle size of 80nm 2 (M) Add 10 g of ethanol containing 0.02% by weight of polyvinylpyrrolidone, stir for 30min; add 5ml of an aqueous solution of 0.1% by weight of silver nitrate and 50ml of an aqueous solution of 1% by weight of sodium borohydride, and stir for 5 hours to obtain a gray suspension , after centrifugal precipitation and vacuum drying, VO with Ag thickness of 10nm was obtained 2 Ag nanocomposite powder; then disperse 0.2g of the powder into 1g of ethanol containing 0.02% by weight of polyvinylpyrrolidone, stir for 1 hour; adjust the pH value to 3, add 1ml of tetraethyl orthosilicate, and stir for 120 minutes , dried at 110°C for 2 hours after centrifugation to obtain SiO 2 VO with a thickness of 100nm 2 AgSiO 2 powder.

Embodiment 2

[0036] First, 2 g of VO with a phase transition temperature of 60 degrees and a particle size of 40 nm 2 (M) Add 30 g of toluene containing 0.04% polyvinyl alcohol, stir for 30 min; add 5 ml of an aqueous solution of 2% by weight of silver nitrate and 50 ml of an aqueous solution of 2% by weight of sodium borohydride, and stir for 5 hours to obtain a gray suspension. After centrifugal precipitation and vacuum drying, VO with an Ag layer thickness of 2 nm was obtained. 2 Ag nanocomposite powder; then disperse 0.2g of this powder into 3g of chloroform containing 0.04% by weight of polyvinyl alcohol, stir for 1 hour, adjust the pH value to 3; add 10ml of saturated aqueous solution of zinc nitrate, and stir for 120 minutes Afterwards, centrifuge and dry at 110°C for 2 hours, ZnO with a thickness of 50nm in VO 2 Powder of AgZnO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com