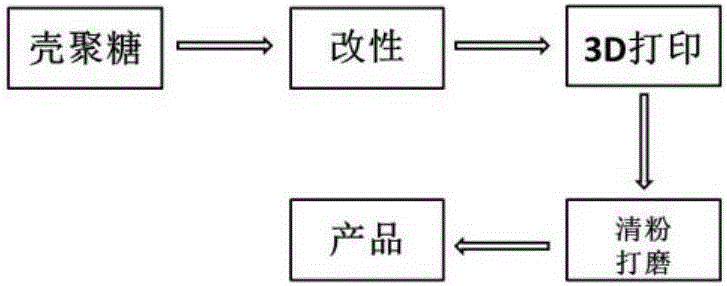

A click chemically modified chitosan material suitable for 3D printing and its preparation method

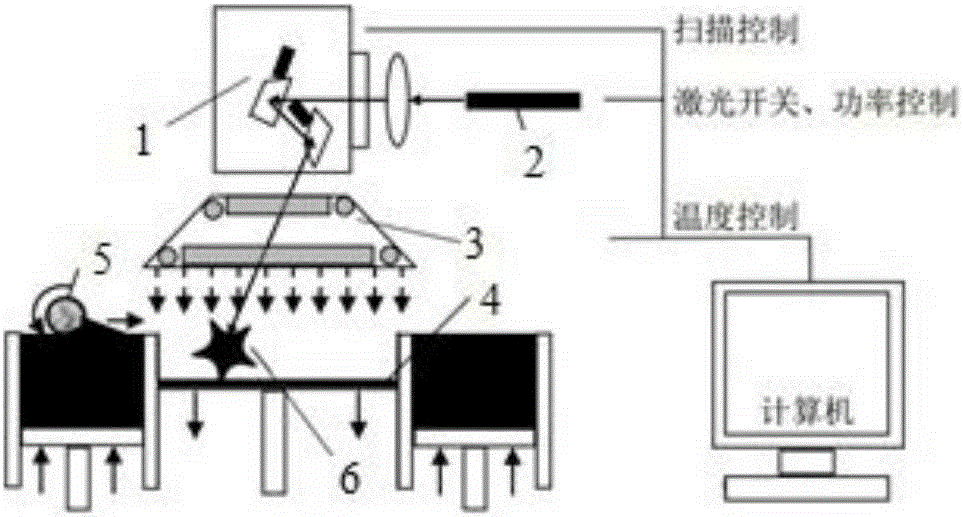

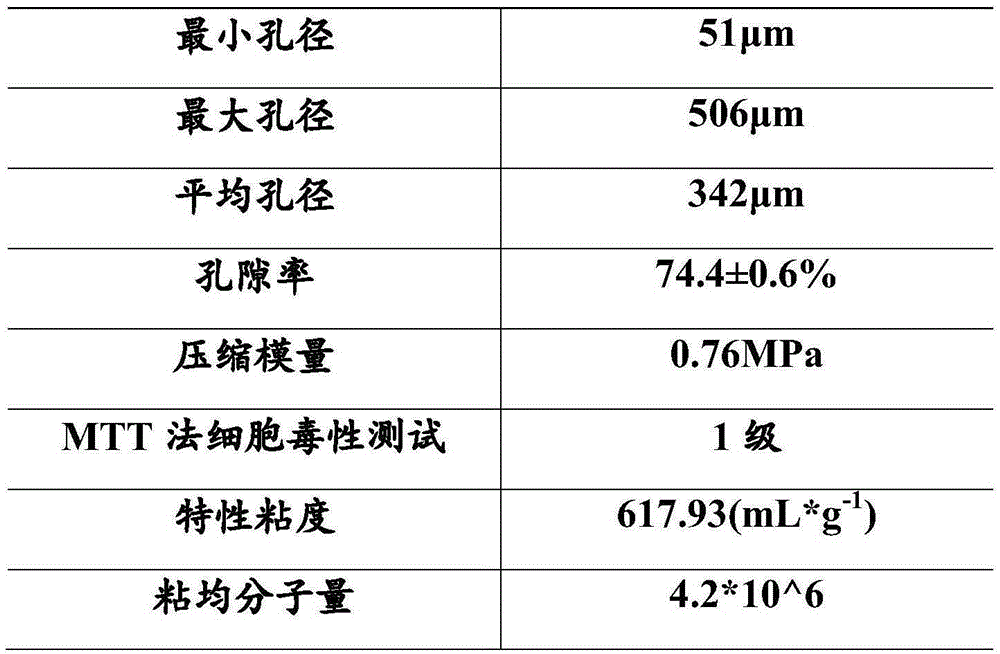

A 3D printing and click chemistry technology, which is applied in the field of 3D printing materials and their preparation, can solve problems such as difficult to meet the mechanical strength of bone materials, and achieve the effects of controllable pore size distribution, improved performance, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation method that the present invention applies:

[0050] 1. Add 2 parts by weight of 7% hydrogen bromide dropwise to 4 parts by weight of mPEG-1000, react at 10°C for 1 hour after the addition is completed, add an appropriate amount of xylene, heat up and reflux, and use a water separator to divide water at the same time, reduce Distill xylene under pressure, wash with acetone twice after cooling, and dry to obtain brominated polyethylene glycol mPEG-Br.

[0051] 2. Dissolve 1 part by weight of sodium azide in an appropriate amount of distilled water, then add the brominated polyethylene glycol obtained in step 1, react at 75°C for 21 hours, cool to 0°C, add appropriate amount of ether and potassium hydroxide, and separate The organic phase and the aqueous phase were extracted three times with excess ether, and the organic phases were combined. After drying overnight with anhydrous magnesium sulfate, it was filtered, and the diethyl ether was removed by rota...

Embodiment 2

[0063] The preparation method that the present invention applies:

[0064] 1. Add 5 parts by weight of 7% hydrogen bromide dropwise to 8 parts by weight of mPEG-2000, react at 10°C for 1 hour after the addition is completed, add an appropriate amount of xylene, heat up and reflux, and use a water separator to separate water at the same time, reduce Distill xylene under pressure, wash with acetone twice after cooling, and dry to obtain brominated polyethylene glycol mPEG-Br.

[0065] 2. Dissolve 2 parts by weight of sodium azide in an appropriate amount of distilled water, then add the brominated polyethylene glycol obtained in step 1, react at 75°C for 21 hours, cool to 0°C, add appropriate amount of ether and potassium hydroxide, and separate The organic phase and the aqueous phase were extracted three times with excess ether, and the organic phases were combined. After drying overnight with anhydrous magnesium sulfate, it was filtered, and the diethyl ether was removed by r...

Embodiment 3

[0074] Embodiment 3: As the optimization of the above-mentioned embodiments, polylactic acid-modified chitosan porous materials were prepared, and the raw materials included high-molecular-weight chitosan, polylactic acid with a low degree of polymerization, sodium azide, hydrogen bromide and propyne bromide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com