Method for preparing biological fuel oil by fast pyrolyzing biomass

A biofuel and biomass technology, applied in the preparation of biofuels, liquid hydrocarbon mixtures, waste fuels, etc., can solve the problems of large hydrogen consumption and low yield, and achieve improved fuel quality, increased yield, and uniform products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

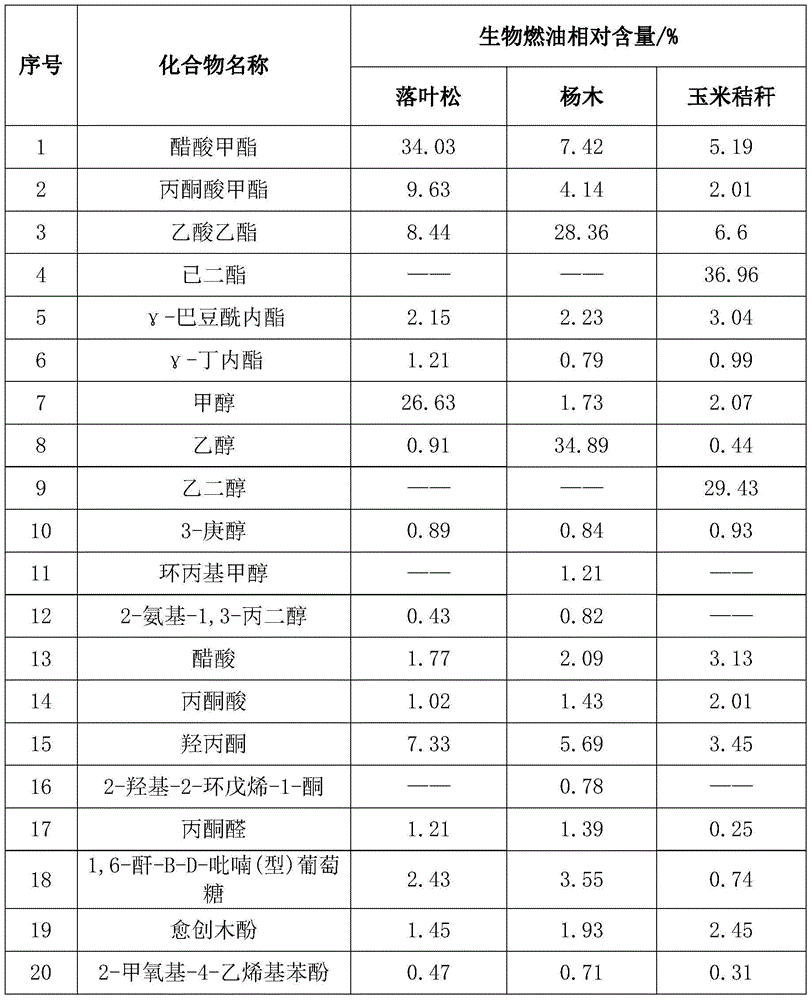

Embodiment 1

[0029] (1) The raw larch with a particle size of 1 mm was immersed in dilute sulfuric acid with a concentration of 0.2% for 1 hour at a temperature of 30 °C, the mass ratio of larch and dilute sulfuric acid was 1:20, filtered after immersion, and dried at 105 °C For 3 hours, the dried product was subjected to steam explosion pretreatment in a high-pressure saturated water vapor environment of 120°C and 1Mpa for 60 seconds, then the pressure was instantly vented to normal pressure, the steam explosion product was added to 20 times the mass of methanol, and stirred for 30 minutes , to obtain methanol extract and steam-exploded larch.

[0030] (2) In 100g of steam-exploded larch, add 1500g of distilled water, 30g of glacial acetic acid, and 50g of sodium chlorite in turn, heat at 50°C for 5 minutes, filter to obtain a solid substance, and wash the solid substance with distilled water until the filtrate is medium. properties, and dried at 105 °C for 5 hours to obtain delignified l...

Embodiment 2

[0032](1) The raw material of poplar with a particle size of 3 mm was impregnated with dilute hydrochloric acid with a concentration of 1% at a temperature of 50 ° C for 0.5 hours, the mass ratio of poplar to dilute hydrochloric acid was 1:40, filtered after dipping, and dried at 105 ° C For 4 hours, the dried product was subjected to steam explosion pretreatment for 45 seconds in a high-pressure saturated water vapor environment of 150°C and 0.8Mpa, and then the pressure was instantly discharged to normal pressure, and the steam explosion product was added to 30 times the mass of ethanol, and stirred for 30 minutes. minutes to obtain ethanol extract and steam-exploded poplar.

[0033] (2) In 100g of steam-exploded poplar, add 2000g of distilled water, 40g of glacial acetic acid, and 80g of sodium chlorite successively, heat at 55°C for 7 minutes, filter to obtain a solid substance, and wash the solid substance with distilled water until the filtrate is neutral , and dried at ...

Embodiment 3

[0035] (1) The raw material of corn stalk with a particle size of 5 mm was impregnated with dilute nitric acid with a concentration of 2% at a temperature of 50 ° C for 1 hour, the mass ratio of corn stalk to dilute sulfuric acid was 1:10, filtered after immersion, and dried at 105 ° C For 5 hours, the dried product was subjected to steam explosion pretreatment in a high-pressure saturated water vapor environment of 145°C and 0.75Mpa for 30 seconds, and then the pressure was instantly discharged to normal pressure, and the steam explosion product was added to 40 times the mass of ethylene glycol, Stir for 30 minutes to obtain ethylene glycol extract and steam-exploded corn stover.

[0036] (2) Add 3000g of distilled water, 50g of glacial acetic acid, and 100g of sodium chlorite to 100g of steam-exploded corn stalks in sequence, heat at 70°C for 10 minutes, and filter to obtain a solid substance. Wash the solid substance with distilled water until the filtrate is Neutral, dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com