A kind of clean extraction method of colored molybdenum lead ore

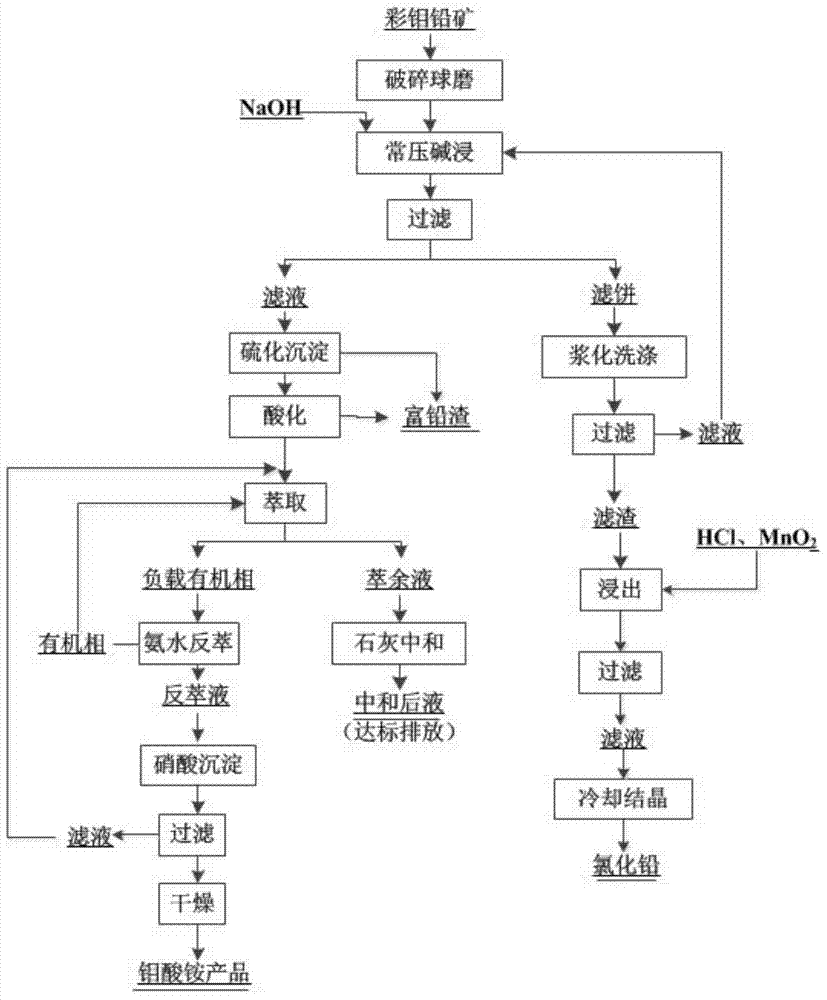

A color molybdenum lead ore and extraction method technology, applied in the field of hydrometallurgy, can solve the problems of long bioleaching cycle and low molybdenum leaching rate, and achieve the effects of clean and environmentally friendly production process, good product quality, and high recovery rate throughout the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] For molybdenite whose main components are Mo2.87%, Pb9.39%, Zn3.37%, Al3.11% and Fe7.05%, after crushing and grinding, it is leached with NaOH. Under the conditions of solid ratio 1:1, leaching time 1h, NaOH concentration 60g / L and stirring speed 300r / min, molybdenum and a part of lead enter into the alkaline leaching solution, the leaching rate of molybdenum reaches 99.7%, and the leaching rate of lead reaches 59%. The rest of the lead goes into the alkaline leaching residue.

[0043] The alkali immersion solution is further treated by sulfide precipitation-stage acidification. The conditions of sulfide precipitation are 95% of the theoretical amount of sodium hydrosulfide, temperature 75°C, and reaction time 30 minutes. After sulfide precipitation, it is filtered, and the filtrate is acidified in two stages with sulfuric acid. In the first stage, acid is added to adjust the pH of the solution to 6.0, and after filtration, the second stage of acidification is carried o...

Embodiment 2

[0047] For the molybdenite whose main components are Mo3.64%, Pb11.59%, Zn3.29%, Al2.81% and Fe6.84%, after crushing and grinding, it is leached with NaOH. Under the conditions of solid ratio of 2:1, leaching time of 0.5h, NaOH concentration of 70g / L and stirring speed of 400r / min, molybdenum and a part of lead enter the alkaline leaching solution, the leaching rate of molybdenum reaches 96.7%, and the leaching rate of lead reaches 52%. , and the rest of the lead enters the alkali leaching residue.

[0048] The alkali immersion solution is further treated by sulfidation precipitation-stage acidification. The sulfide precipitation conditions are 95% of the theoretical amount of sodium sulfide, temperature 75°C, and reaction time 30 minutes. After sulfide precipitation, it is filtered, and the filtrate is acidified in two stages with sulfuric acid. The pH of the solution is adjusted to 6.0 by adding acid in one stage, and the second stage of acidification is carried out after fi...

Embodiment 3

[0052] For molybdenite whose main components are Mo7.05%, Pb24.16%, Zn1.84%, Al0.4% and Fe13.52%, after crushing and grinding, it is leached with KOH. Under the conditions of solid ratio 3:1, leaching time 5h, KOH concentration 60g / L and stirring speed 400r / min, molybdenum and a part of lead enter into the alkali leaching solution, the leaching rate of molybdenum reaches 94.7%, and the leaching rate of lead reaches 29%. The rest of the lead goes into the alkaline leaching residue.

[0053] The alkali immersion solution is further treated by sulfidation precipitation-stage acidification. The sulfide precipitation conditions are 95% of the theoretical amount of sodium sulfide, temperature 75°C, and reaction time 30 minutes. After sulfide precipitation, it is filtered, and the filtrate is acidified in two stages with sulfuric acid. The pH of the solution is adjusted to 6.0 by adding acid in one stage, and the second stage of acidification is carried out after filtration, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com