Welding wire for welding fv520b martensitic stainless steel and preparation method thereof

A martensitic stainless steel, FV520B technology, applied in welding equipment, welding/welding/cutting items, welding media, etc., can solve the problem of high cost and achieve the effect of good filling rate, good fluidity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

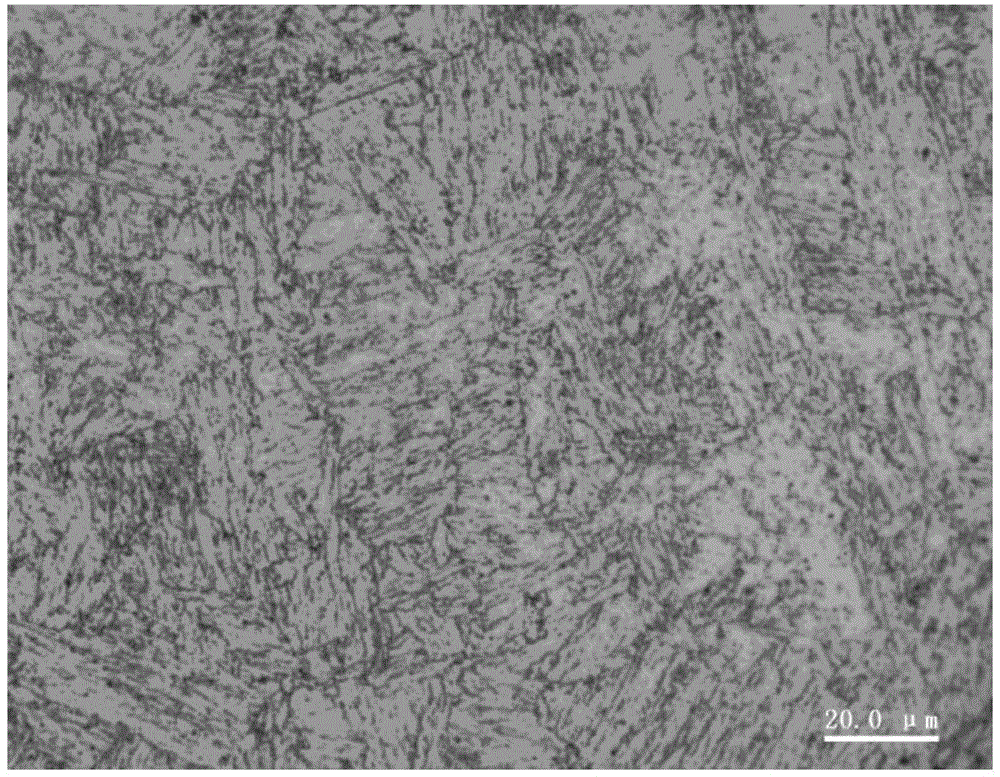

Embodiment 1

[0054] Step 1, take by mass percentage respectively 30% rutile, 6% zircon sand, 2% quartz, 6% feldspar, 4% sodium carbonate (Na 2 CO 3 ), 3% aluminum oxide (Al 2 o 3 ), 6% aluminum-magnesium alloy (Al-Mg), 5% electrolytic manganese metal (Mn), 20% chromium powder (Cr), 10% nickel powder (Ni), 4% ferroniobium (Nb- Fe), 4% molybdenum powder (Mo), the sum of the mass percentages of each component is 100%;

[0055] Step 2, dry-mix rutile, zircon sand, quartz, feldspar, sodium carbonate and aluminum oxide in a powder mixer for 0.5h, then put them into a spray granulator, and use water as a binder for granulation Granules, the particle size is controlled at 2-3mm;

[0056] Step 3, sintering the granules obtained in step 2 at 700°C for 0.8h, and then crushing them, and screening out the medicinal powder with a particle size of 60-100 mesh;

[0057] Step 4, uniformly mixing the medicinal powder obtained in step 3 with aluminum-magnesium alloy, electrolytic metal manganese, chromi...

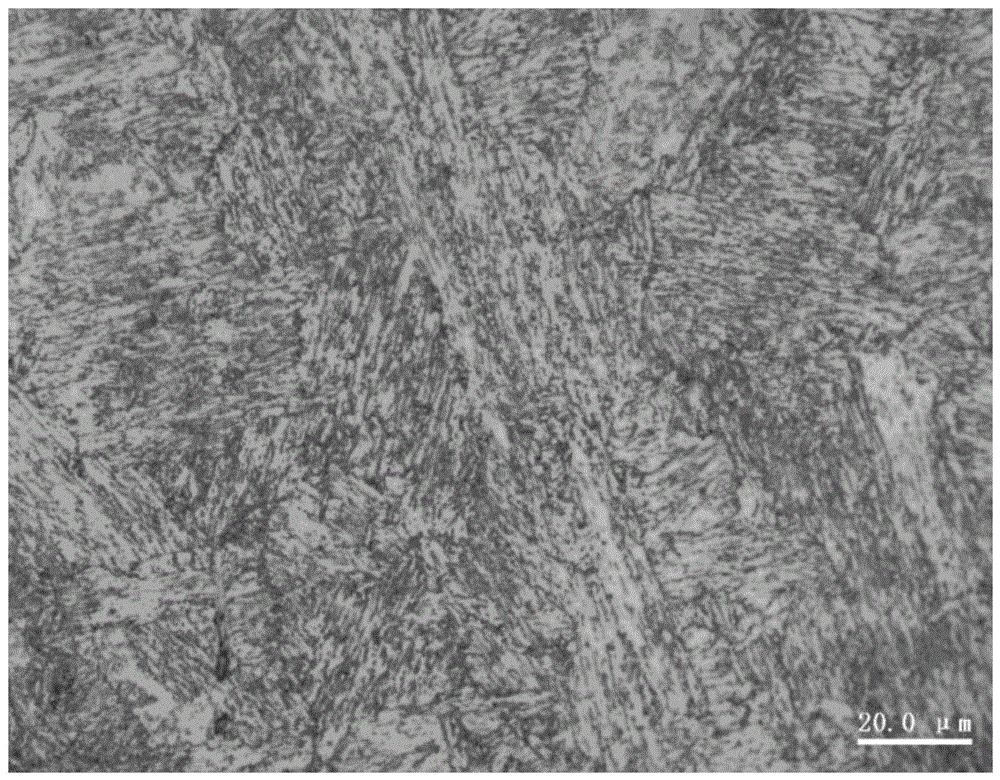

Embodiment 2

[0067] Step 1, take by weight respectively 25% rutile, 5% zircon sand, 2% quartz, 7% feldspar, 5% sodium carbonate (Na 2 CO 3 ), 3% aluminum oxide (Al 2 o 3 ), 7% aluminum-magnesium alloy (Al-Mg), 6% electrolytic metal manganese (Mn), 25% chromium powder (Cr), 6% nickel powder (Ni), 4% ferroniobium (Nb- Fe), 5% molybdenum powder (Mo), the sum of the mass percentages of each component is 100%;

[0068] Step 2, dry-mix rutile, zircon sand, quartz, feldspar, sodium carbonate and aluminum oxide in a powder mixer for 0.6h, then put them into a spray granulator, and use water as a binder for granulation Granules, the average particle size of the particles is controlled at 2-3mm;

[0069] Step 3, sintering the granules obtained in step 2 for 0.7 hours at 720° C. and then crushing, and screening out the powder with a particle size of 60 to 100 mesh;

[0070] Step 4, uniformly mixing the medicinal powder obtained in step 3 with aluminum-magnesium alloy, electrolytic metal manganese,...

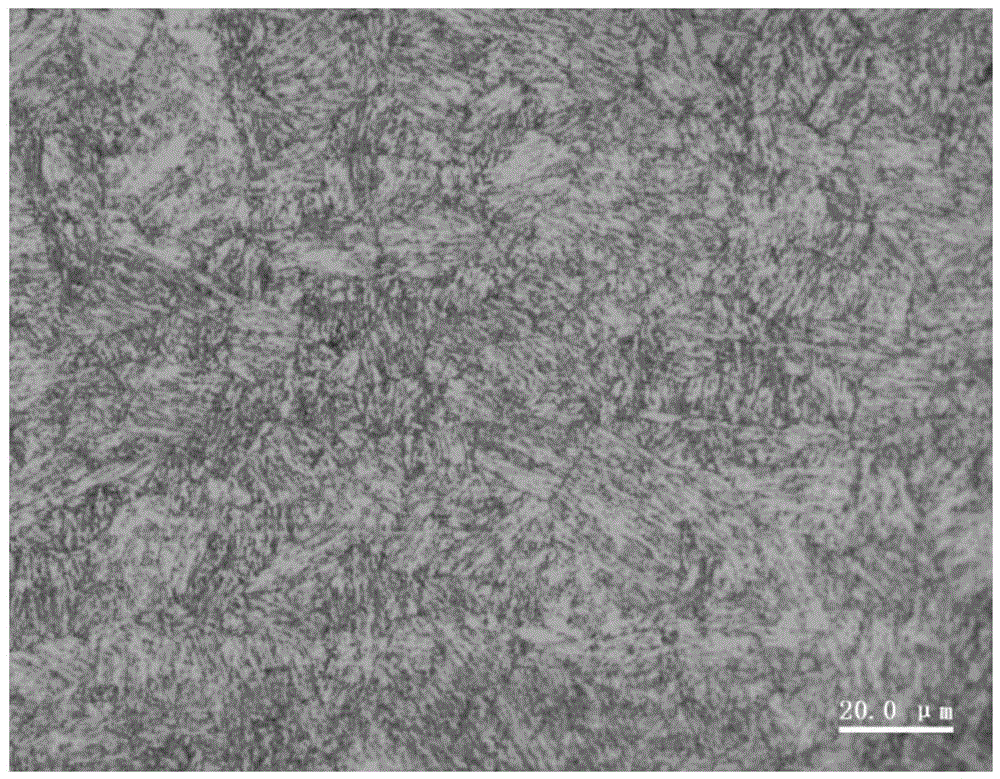

Embodiment 3

[0080] Step 1, take by weight respectively 28% rutile, 7% zircon sand, 4% quartz, 10% feldspar, 2% sodium carbonate (Na 2 CO 3 ), 2% aluminum oxide (Al 2 o 3 ), 10% aluminum-magnesium alloy (Al-Mg), 5% electrolytic metal manganese (Mn), 18% chromium powder (Cr), 7% nickel powder (Ni), 3% ferroniobium (Nb- Fe), 4% molybdenum powder (Mo), the sum of the mass percentages of each component is 100%;

[0081] Step 2, dry-mix rutile, zircon sand, quartz, feldspar, sodium carbonate and aluminum oxide in a powder mixer for 0.7h, then put them into a spray granulator, and use water as a binder for granulation Granules, the average particle size of the particles is controlled at 2-3mm;

[0082] Step 3, sintering the granules obtained in step 2 for 0.5 h at 750° C. and then breaking them, and screening out the powder with a particle size of 60 to 100 mesh;

[0083] Step 4, uniformly mixing the medicinal powder obtained in step 3 with aluminum-magnesium alloy, electrolytic metal manga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com