Manufacturing method for high-performance NdFeB rare earth permanent magnet devices

一种稀土永磁、制造方法的技术,应用在电感/变压器/磁铁制造、磁性材料、电气元件等方向,能够解决稀土短缺、工艺研究不够深入、纳米氧化物易吸潮等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

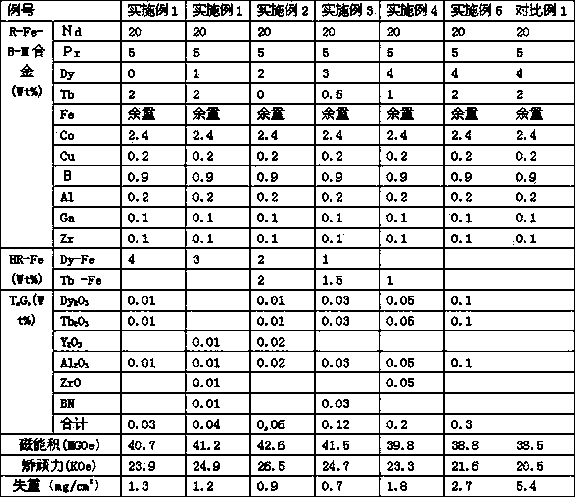

Embodiment 1

[0051] According to the composition in Table 1, 600Kg of R-Fe-B-M alloy is selected for melting, and the alloy is cast on a rotating copper roll with water cooling in the molten state to cool to form an alloy sheet; Manufactured in a quenching furnace, the rotational speed of the molybdenum wheel is selected to be 15m / s; the microcrystalline Dy-Fe alloy fiber and the R-Fe-B-M alloy sheet are selected according to the ratio listed in Table 1 for hydrogen crushing, and the microcrystalline Dy-Fe alloy after hydrogen crushing The fiber and the R-Fe-B-M alloy sheet are put into the mixer together, and then T is added according to the ratio in Table 1. m G n Chemical powder, mixed under the protection of nitrogen, the mixing time is 60 minutes, jet milling after mixing, the powder collected by the cyclone collector and the ultrafine powder collected by the filter are put into the post-mixer for further processing Post-mixing, the post-mixing is also carried out under the protectio...

Embodiment 2

[0053] Select 600Kg of R-Fe-B-M alloy according to the composition in Table 1 for smelting, inductively heat and melt the R-Fe-Co-B-M raw material under vacuum or argon protection to form an alloy, refine it at 1400-1470°C, and melt the molten alloy liquid after refining Casting through the tundish on the rotating roller with water cooling, the rotating roller speed is 1m / s, the molten alloy is cooled by the rotating roller to form alloy flakes, and the alloy flakes leave the rotating copper roller and then fall on the turntable for secondary cooling; HR-Fe alloy fiber (80%HR) is manufactured by vacuum quenching furnace, and the rotation speed of molybdenum wheel is 18m / s respectively; microcrystalline Dy-Fe alloy fiber and R-Fe-B-M alloy sheet are selected according to the ratio listed in Table 1. Hydrogen crushing, the microcrystalline Dy-Fe alloy fibers and R-Fe-B-M alloy sheets after hydrogen crushing are put into the mixer together, and then add T m G n Chemical powder, ...

Embodiment 3

[0055] Select 600Kg of R-Fe-B-M alloy according to the composition in Table 1 for smelting, inductively heat and melt the R-Fe-Co-B-M raw material under vacuum or argon protection to form an alloy, refine it at 1400-1470°C, and melt the molten alloy liquid after refining Casting through the tundish on the rotating roller with water cooling, the rotating roller speed is 2m / s, the molten alloy is cooled by the rotating roller to form alloy flakes, and the alloy flakes fall immediately after leaving the rotating copper roller, and the alloy flakes are broken after falling. Enter the receiving box, and then cool the alloy sheet with an inert gas; the microcrystalline HR-Fe alloy fiber (80%HR) is manufactured by a vacuum quenching furnace, and the rotation speed of the molybdenum wheel is respectively selected at 22m / s; the ratio listed in Table 1 is selected The microcrystalline Dy-Fe alloy fibers and R-Fe-B-M alloy sheets are subjected to hydrogen crushing, and the microcrystallin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com