Silicon-based ferroelectric grid thin film transistor and preparation method thereof

A technology of thin-film transistors and transistors, applied in transistors, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as incompatibility, high price, and restrictions on the application and development of ferroelectric gate thin-film transistors, and achieve low turn-on voltage and low cost , easy process compatible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

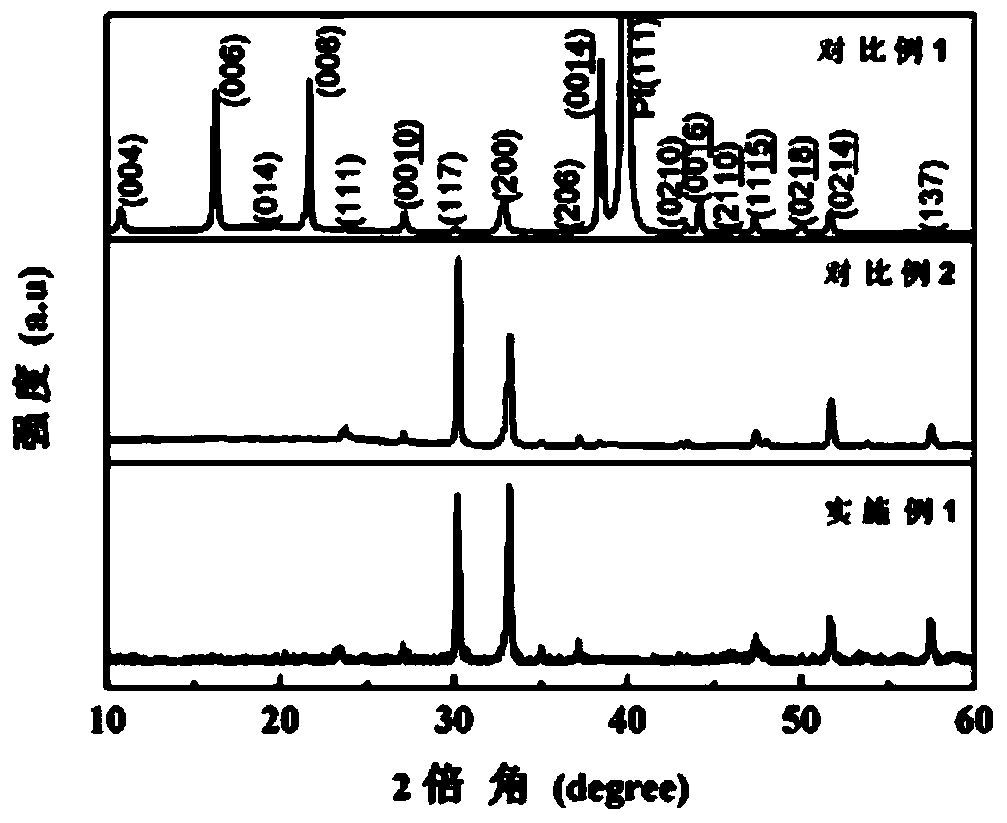

Embodiment 1

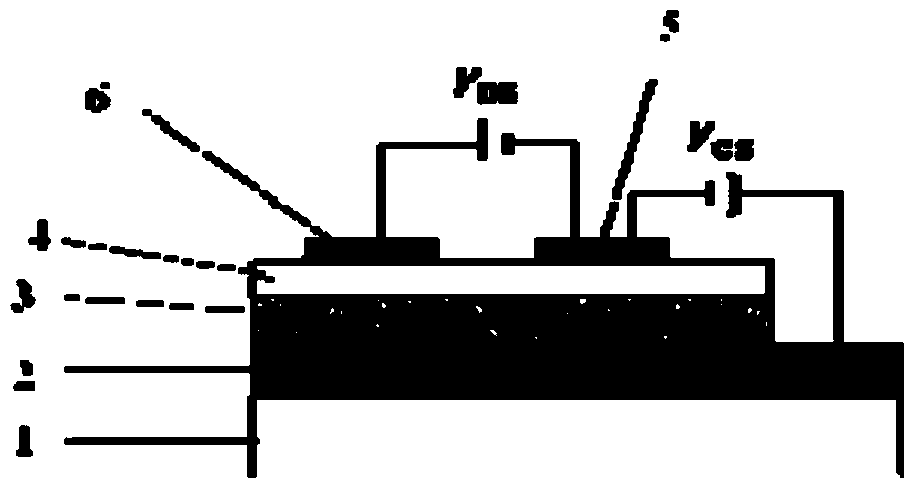

[0044] In this example, LaNiO was prepared on a Si(100) substrate with an offcut angle θ of 6° in the [100] direction by pulsed laser deposition. 3 Thin film as bottom gate electrode, Bi 3.15 Nd 0.85 Ti 3 o 12 A ferroelectric gate thin film transistor with a ferroelectric thin film as an insulating layer and a ZnO thin film as an active layer, comprising the following steps:

[0045] (1) Installation of substrate and target

[0046] In a vacuum chamber, the LaNiO 3 、 Bi 3.15 Nd 0.85 Ti 3 o 12 and the ZnO target are installed on the multi-target rack, and the obliquely cut Si substrate is cleaned and installed on the substrate rack so that the direction of the laser beam is aligned with the LaNiO 3 For the target, adjust the distance between the substrate and the target to 87mm.

[0047] (2) vacuuming

[0048] Turn on the mechanical pump and the molecular pump in sequence to pump the pressure in the vacuum chamber to 5×10 -8 Torr.

[0050...

Embodiment 2

[0057] In this example, LaNiO was prepared on a Si(001) substrate with an off-cut angle θ of 6° in the [100] direction by pulsed laser deposition. 3 Thin film as bottom gate electrode, Pb(Zr 0.53 Ti 0.47 )O 3 A ferroelectric gate thin film transistor with a ferroelectric thin film as an insulating layer and a ZnO thin film as an active layer, comprising the following steps:

[0058] (1) Installation of substrate and target

[0059] The selected ferroelectric material target is Pb(Zr 0.53 Ti 0.47 )O 3 Target material, all the other are the same as embodiment 1.

[0060] (2) vacuuming

[0061] Same as Example 1

[0063] NeO 3 The deposited oxygen pressure is 50mTorr, resulting in highly c-axis oriented LaNiO 3 Thin film, its thickness is 50nm; Pb(Zr 0.53 Ti 0.47 )O 3 The deposition oxygen pressure of the ferroelectric thin film is 100mTorr, and the deposition temperature is 600°C, and the Pb(Zr 0.53 Ti 0.47 )O 3 Ferroelectric layer thin...

Embodiment 3

[0067] In this example, LaNiO was prepared on a Si(100) substrate with an offcut angle θ of 5° in the [110] direction by pulsed laser deposition. 3 Thin film as bottom gate electrode, Bi 3.25 La 0.75 Ti 3 o 12 Ferroelectric thin film as insulating layer, In 2 o 3 : Sn thin film is used as the ferroelectric gate thin film transistor of active layer, comprises the following steps:

[0068] (1) Installation of substrate and target

[0069] The selected ferroelectric material target and oxide semiconductor target are Bi 3.25 La 0.75 Ti 3 o 12 Target and In 2 o 3 : Sn target material, all the other are with embodiment 1.

[0070] (2) vacuuming

[0071] Same as Example 1

[0073] Bi 3.25 La 0.75 Ti 3 o 12The deposition oxygen pressure of the ferroelectric thin film is 250mTorr, the deposition temperature is 750℃, and the Bi with a-axis preferred orientation is obtained. 3.25 La 0.75 Ti 3 o 12 Ferroelectric thin film, its thickness is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bevel angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com