Cationic-nonionic water-based polyurethane-polyacrylate composite emulsion and preparation method thereof

A technology of water-based polyurethane and polyacrylate, which is applied in coatings, textiles, papermaking, fiber treatment, etc. It can solve the problems of large emulsion particle size, complicated process, and many steps, and achieve good cross-linking function, advanced preparation method, The effect of excellent surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

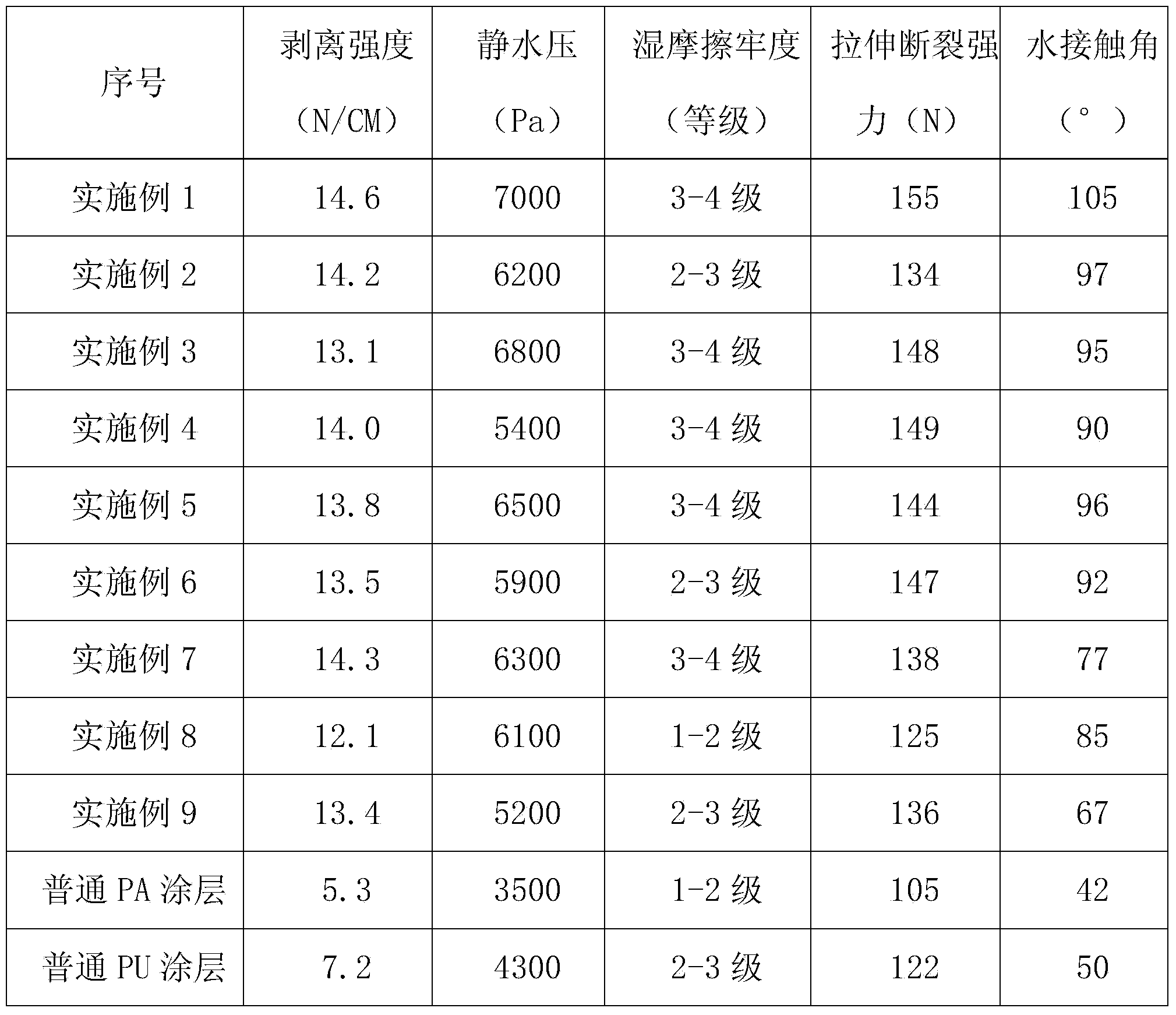

Examples

Embodiment 1

[0034] Dehydrate 120g of polybutylene adipate at 120°C under high temperature and vacuum conditions, then lower it to 70°C, slowly add 87g of toluene diisocyanate, react at 85-90°C for 1 hour, add 5.4g of butanediol Alcohol, react at 85-90°C for 1 hour; then lower the temperature to 50°C, slowly add a mixture of 20g butanone and 12g N-methyldiethanolamine dropwise, drop the mixture in 1 hour, then raise the temperature to 65°C, and keep it warm for 2 hours to obtain NCO-terminated prepolymer, adding 70g butanone to dilute and cool down; slowly add 10g hydroxypropyl acrylate and 7g butanone oxime dissolved in 20g butanone to the NCO-terminated prepolymer, react at 60°C for 1.5 Hours later, lower the temperature to 45°C, add 6g of acetic acid for quaternization, then slowly add 735g of deionized water for emulsification, and finally extract the butanone therein to obtain a chemically bonded self-emulsifying PU seed emulsion; The dosage is regarded as 100 parts. Based on this, 15...

Embodiment 2

[0036] Dehydrate 125g of polyethylene glycol at 120°C under high temperature and vacuum conditions, then lower it to 70°C, slowly add 111g of isophorone diisocyanate, react at 85-90°C for 1 hour, add 6.4g of diisocyanate Ethylene glycol, react at 85-90°C for 1 hour; then lower the temperature to 50°C, slowly add a mixture of 20g of butanone and 24.1g of N-benzyldiethanolamine dropwise, drop it in 1 hour, then raise the temperature to 65°C, and keep warm for 2 Hour, obtain the prepolymer of terminal NCO, add 70g methyl ethyl ketone and carry out diluting cooling during this period; 11g hydroxypropyl methacrylate and 4.5g methyl ethyl ketone oxime and 2g cyclohexanone oxime that are dissolved in 20g methyl ethyl ketone are slowly added to In the NCO-terminated prepolymer, after reacting at 60°C for 1.5 hours, lower the temperature to 40°C, add 6.5g of acetic acid for quaternization, then slowly add 740g of deionized water for emulsification, and finally extract the methyl ethyl k...

Embodiment 3

[0038] Dehydrate 156g of polypropylene glycol at 120°C under high temperature and vacuum conditions, then lower it to 70°C, slowly add 125g of diphenylmethane diisocyanate, react at 85-90°C for 1 hour, add 7g of ethylene glycol, 85- React at 90°C for 1 hour; then lower the temperature to 50°C, slowly add a mixture of 20g of butanone and 16.1g of tert-butyldiethanolamine dropwise, drop the mixture in 1 hour, then raise the temperature to 65°C, and keep it warm for 2 hours to obtain the NCO-terminated precursor Add 80g methyl ethyl ketone to dilute and lower the temperature; slowly add 12g hydroxybutyl acrylate and 9gξ-caprolactam dissolved in 20g methyl ethyl ketone to the NCO-terminated prepolymer, react at 60°C for 1.5 hours, then lower the temperature To 45°C, add 6g of acetic acid for quaternization, then slowly add 685g of deionized water for emulsification, and finally extract the butanone in it to obtain a chemically bonded self-emulsifying PU seed emulsion; the amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com