Method for preparing aluminum oxide ceramic fibers

A technology of ceramic fiber and alumina sol, which is applied in the direction of inorganic raw material artificial filament, etc., can solve the problems of poor flexibility, low strength, high porosity, etc., and achieve good high temperature resistance, good flexibility and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Technical scheme of the present invention is as follows:

[0008] a kind of Al 2 o 3 The preparation method of ceramic fiber comprises steps as follows:

[0009] (1) Preparation of spinnable precursor sol

[0010] Silica sol was added to the Al 13 Colloidal alumina sol, so that Al 2 o 3 and SiO 2 The mass ratio is 1: (0.25-0.67), stirred and mixed evenly, and then aged in a water bath at 30-80°C to a viscosity of 10-160Pa·s to obtain a precursor sol; the Al in the alumina sol 13 The mass content of colloidal particles is 15-50%;

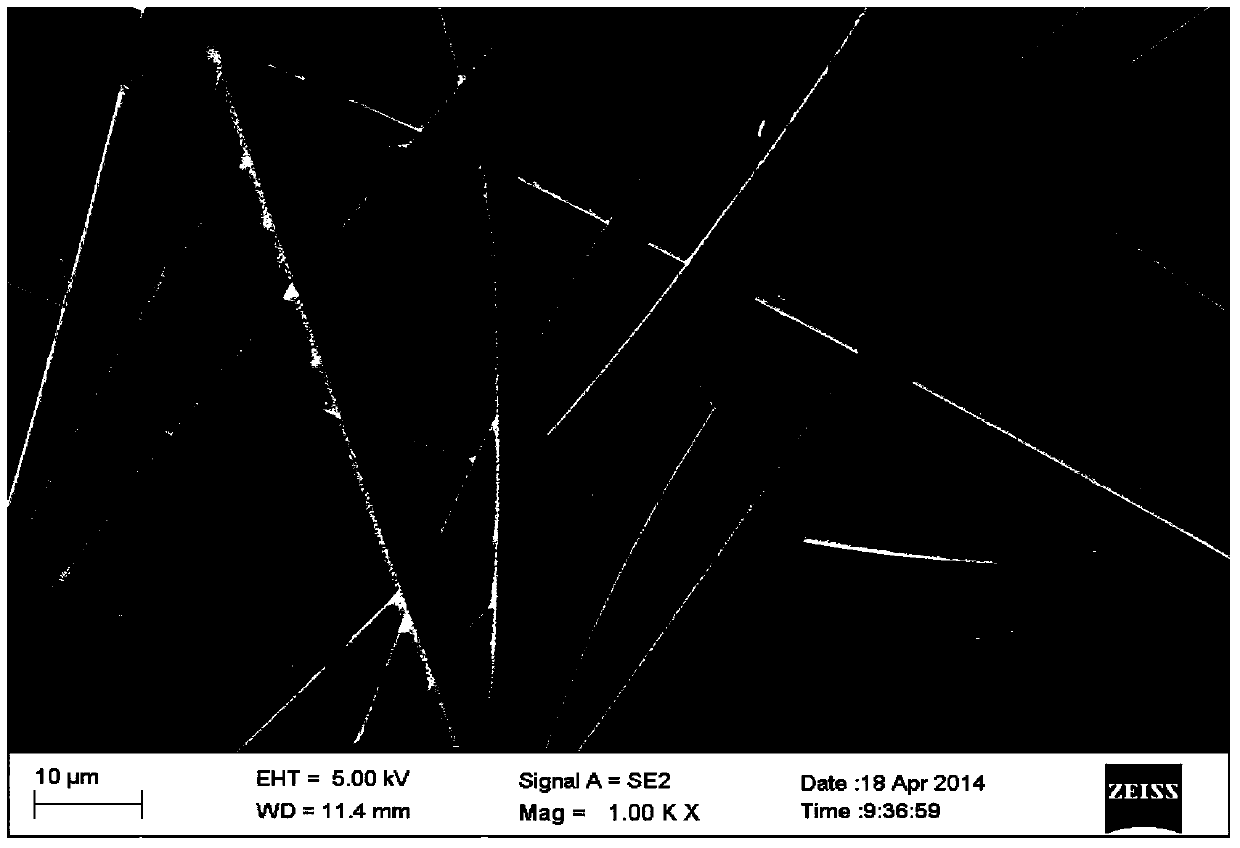

[0011] (2) Preparation of gel fibers by blowing into fibers

[0012] The precursor sol prepared in step (1) is blown into fibers to obtain gel fibers; process conditions: the inner diameter of the spinneret hole is 0.03-0.20mm, the pressure is 5-16MPa, the air temperature is 20-100°C, and the air flow rate is 5~80m / min;

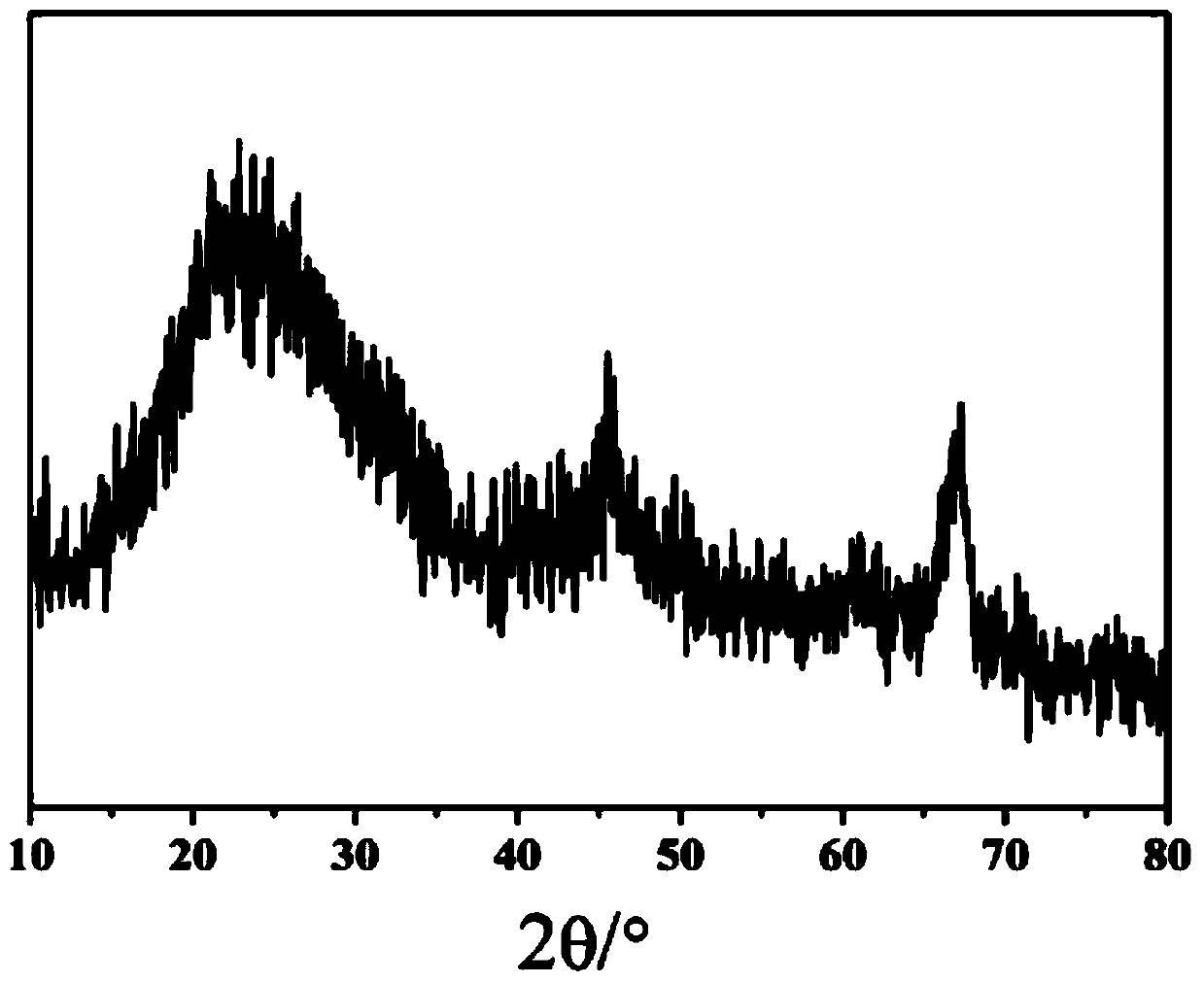

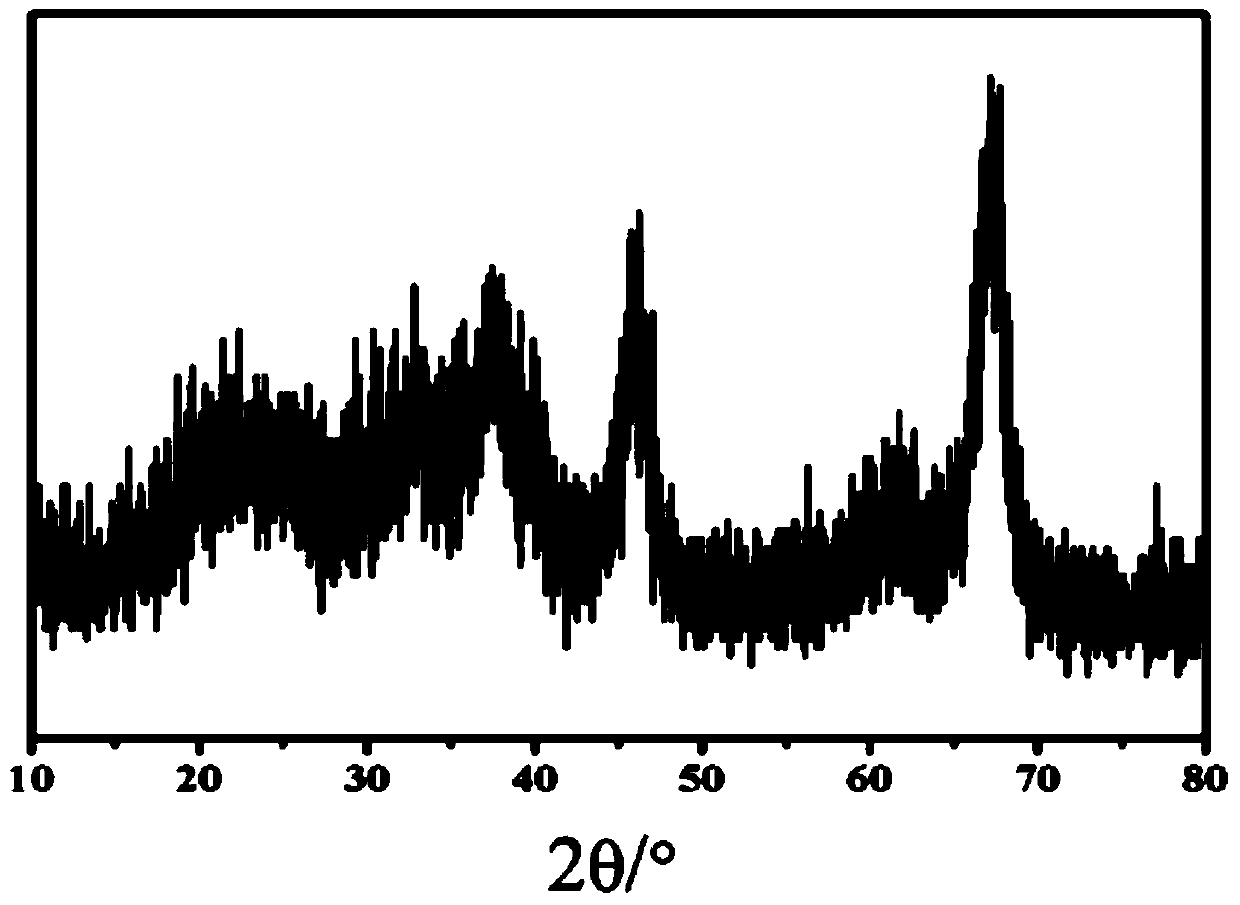

[0013] (3) Gel fiber ceramicization

[0014] The gel fiber prepared in step (2) is ceramicized, and the process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity at room temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com