Medical multifunctional goggle lens and manufacturing method thereof

A goggles, multi-functional technology, applied in goggles, glasses/goggles, optics, etc., can solve the problems of poor anti-blue light effect, high cost, limited effect, etc., to achieve convenient material acquisition, long service life, and reduce shrinkage rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

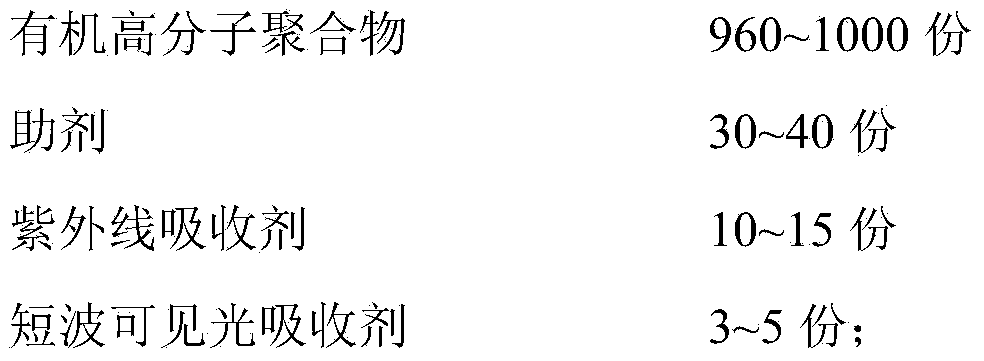

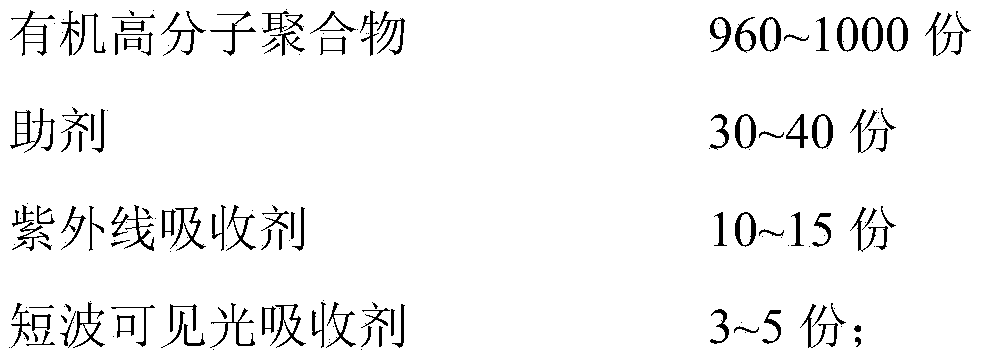

[0040] A kind of medical multifunctional goggle lens of this embodiment is made up of two parts of substrate and surface film layer.

[0041] The substrate is injection molded by mixing organic polymers, additives, ultraviolet absorbers and short-wave visible light absorbers, wherein the organic polymers are optical resins; the additives are composed of stearamide, epoxy soybean oil and styrene It is formulated by mixing the following components and contents: stearamide 8kg, epoxidized soybean oil 6kg, styrene 13kg, stearamide as a dispersant to make the dispersion of ultraviolet absorber and short-wave visible light absorber more uniform and ensure the quality of the lens; Oxygenated soybean oil is used as a stabilizer and plasticizer to improve the mechanical strength of the lens, which is beneficial to the later processing of glasses, and has a good light stabilization effect; styrene improves the bending strength and mechanical properties of the lens, and reduces the lens f...

Embodiment 2

[0052] A kind of medical multifunctional goggle lens of this embodiment is made up of two parts of substrate and surface film layer.

[0053] The substrate is injection molded by mixing organic polymers, additives, ultraviolet absorbers and short-wave visible light absorbers, wherein the organic polymers are polycarbonate (PC); the additives are composed of stearamide, epoxidized soybean oil It is mixed with styrene according to the following components and content: stearamide 9kg, epoxidized soybean oil 7kg, styrene 14kg, stearamide as a dispersant, so that the ultraviolet absorber and short-wave visible light absorber can be dispersed more uniformly, ensuring Lens quality; epoxy soybean oil acts as a stabilizer and plasticizer, which makes the mechanical strength of the lens better, which is conducive to the later processing of glasses, and has a good light stabilization effect; styrene improves the bending strength and mechanical properties of the lens, The shrinkage rate o...

Embodiment 3

[0064] A kind of medical multifunctional goggle lens of this embodiment is made up of two parts of substrate and surface film layer.

[0065] The substrate is injection molded by mixing organic polymers, additives, ultraviolet absorbers and short-wave visible light absorbers, wherein the organic polymers are polymethyl methacrylate (PMMA); the additives are made of stearamide, cyclo Oxygenated soybean oil and styrene are mixed and prepared according to the following components and contents: stearamide 10kg, epoxidized soybean oil 8kg, styrene 15kg, stearamide as a dispersant to make the dispersion of ultraviolet absorbers and short-wave visible light absorbers easier Uniformity ensures the quality of the lens; epoxy soybean oil acts as a stabilizer and plasticizer to improve the mechanical strength of the lens, which is beneficial to the later processing of glasses and has good light stabilization; styrene improves the bending strength and Mechanical properties reduce the shri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com