Preparation method of graphene-based nanosilicon compound electrode material

A graphene-based, electrode material technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low capacity of silicon alloys, difficulty in uniform compounding, complicated process, etc., and achieve high discharge capacity, uniform dispersion, and good cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

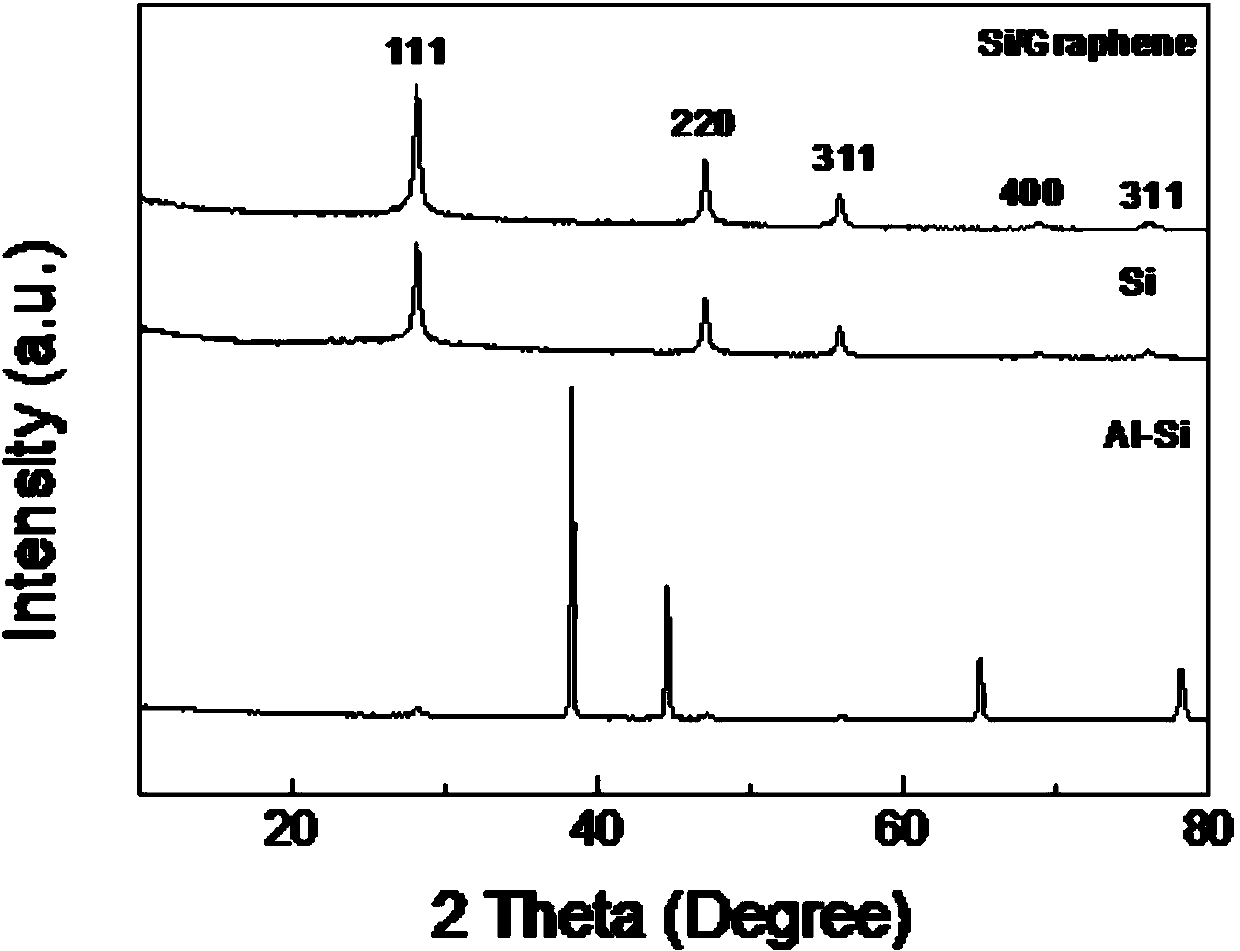

[0023] Disperse 0.2 grams of graphene oxide in 100 milliliters of 3 mol / liter hydrochloric acid solution, then weigh 8.5 grams of aluminum-silicon alloy (graphene content is 10%), add in the above-mentioned acid solution, react for 24 hours, wait for reaction No bubbles are generated, filtered, washed the solid, and dried in a vacuum oven at 80°C to obtain the silicon / graphene composite. The resulting complex looks like figure 2 As shown, it can be seen from the TEM image of the nano-silicon / graphene powder that the silicon particles are less than 10 μm and have an obvious nano-fishbone structure. The fine and dense pores in the particles are formed after the aluminum component in the silicon-aluminum alloy reacts with hydrochloric acid to dissolve and lose. The fine pores are evenly distributed throughout the particle. Nano-silicon and graphene are tightly combined. figure 1 is the XRD pattern of porous silicon powder. In the figure, the characteristic diffraction peaks ...

Embodiment 2

[0025] 0.2 gram of graphene oxide is dispersed in 100 milliliters of 1 mol / liter of sulfuric acid, and then 12 grams of magnesium-silicon alloy (graphene content is 8%) is weighed, added in the above-mentioned acid solution, and reacted for 12 hours. Bubbles are generated, filtered, the solid is washed, and dried in a vacuum oven at 80°C to obtain a silicon / graphene composite.

Embodiment 3

[0027] 0.2 gram of graphene oxide is dispersed in 100 milliliters of 5 mol / liter oxalic acid, and then 5 grams of magnesium-silicon alloy (graphene content is 16%) is weighed, added in the above-mentioned acid solution, and reacted for 36 hours. Bubbles are generated, filtered, the solid is washed, and dried in a vacuum oven at 80°C to obtain a silicon / graphene composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com