A preparation method of organosilicon-containing pesticide microcapsules

A technology of organosilicon and microcapsules, which is applied in the field of preparation of organosilicon-containing pesticide microcapsules, can solve the problems that the spreading performance of microcapsules needs to be further improved, and achieve the effects of improving spreading ability, low surface tension, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

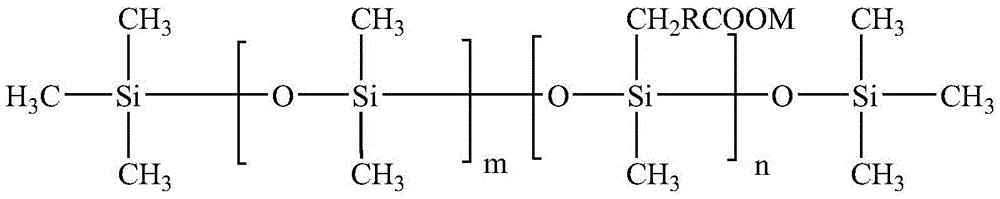

[0026] The gelatin was formulated into 40 grams of an aqueous solution with a mass ratio concentration of 10%, and 8.0 grams of an organosilicon carboxylate potassium surfactant with a number average molecular weight of 48202, and kept warm at 45° C. for subsequent use. The sodium carboxymethyl cellulose is made into 20 grams of an aqueous solution with a mass ratio concentration of 1.0%, and it is kept warm at 80° C. for subsequent use;

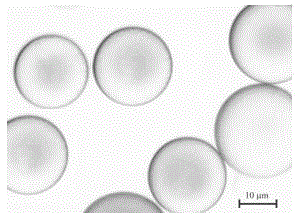

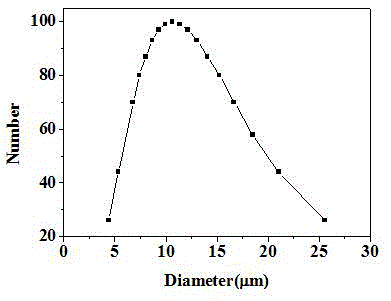

[0027] Add the auxiliary agent to 12.2 grams of permethrin emulsifiable concentrate with a mass ratio concentration of 20%, ultrasonically vibrate at 45°C to make it a uniformly dispersed pesticide suspension, and add it to the above-mentioned gelatin / sodium carboxymethylcellulose / organic silicon carboxylate Potassium acid aqueous solution, disperse at a stirring rate of 500rpm for 30 minutes to obtain an O / W emulsion, and use 20% acetic acid aqueous solution at 45°C to reduce the pH value of the system to 4.5, and slowly lower the temperatur...

Embodiment 2

[0029] The gelatin was made into 32 grams of an aqueous solution with a mass ratio concentration of 10%, and 3.2 grams of an organosilicon sodium carboxylate surfactant with a number average molecular weight of 778, and kept warm at 60° C. for subsequent use. Sodium carboxymethyl cellulose was made into 320 grams of an aqueous solution with a mass ratio concentration of 1.0%, and it was kept warm at 70°C for subsequent use;

[0030] Auxiliary agent and 1.92 grams of carbaryl original drug are added in tetrachlorethylene, ultrasonic vibration makes it become the evenly dispersed pesticide suspension that mass ratio concentration is 10% at 45 ℃, joins above-mentioned gelatin / carboxymethyl fiber Disperse in plain sodium / organosilicon sodium carboxylate aqueous solution for 100 minutes at a stirring rate of 350rpm to obtain an O / W type emulsion. At 45°C, use 10% citric acid aqueous solution to reduce the pH value of the system to 4.5. During stirring, The temperature is slowly low...

Embodiment 3

[0032] The gelatin was formulated into 50 grams of an aqueous solution with a mass ratio concentration of 10%, and 1.0 grams of an organosilicon sodium carboxylate surfactant with a number average molecular weight of 47242, and kept warm at 45° C. for subsequent use. Sodium carboxymethyl cellulose is made into 100 grams of an aqueous solution with a mass ratio concentration of 1.0%, and it is kept warm at 90° C. for subsequent use;

[0033] Add the adjuvant and 70 grams of amecarb original drug into perchlorethylene, and ultrasonically vibrate at 45°C to make it a uniformly dispersed pesticide suspension, and add it to the above-mentioned gelatin / sodium carboxymethylcellulose / organic silicon carboxylic acid Disperse in sodium aqueous solution for 1 minute at a stirring rate of 1000rpm to obtain an O / W emulsion. At 45°C, use 0.05% sulfuric acid aqueous solution to reduce the pH value of the system to 4.5, and slowly lower the temperature to 0°C during stirring. Add 3 ml of 37% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com