Method for recovering waste hard alloy

A technology of cemented carbide and dielectric, applied in the field of metallurgy, to achieve the effect of short process flow and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

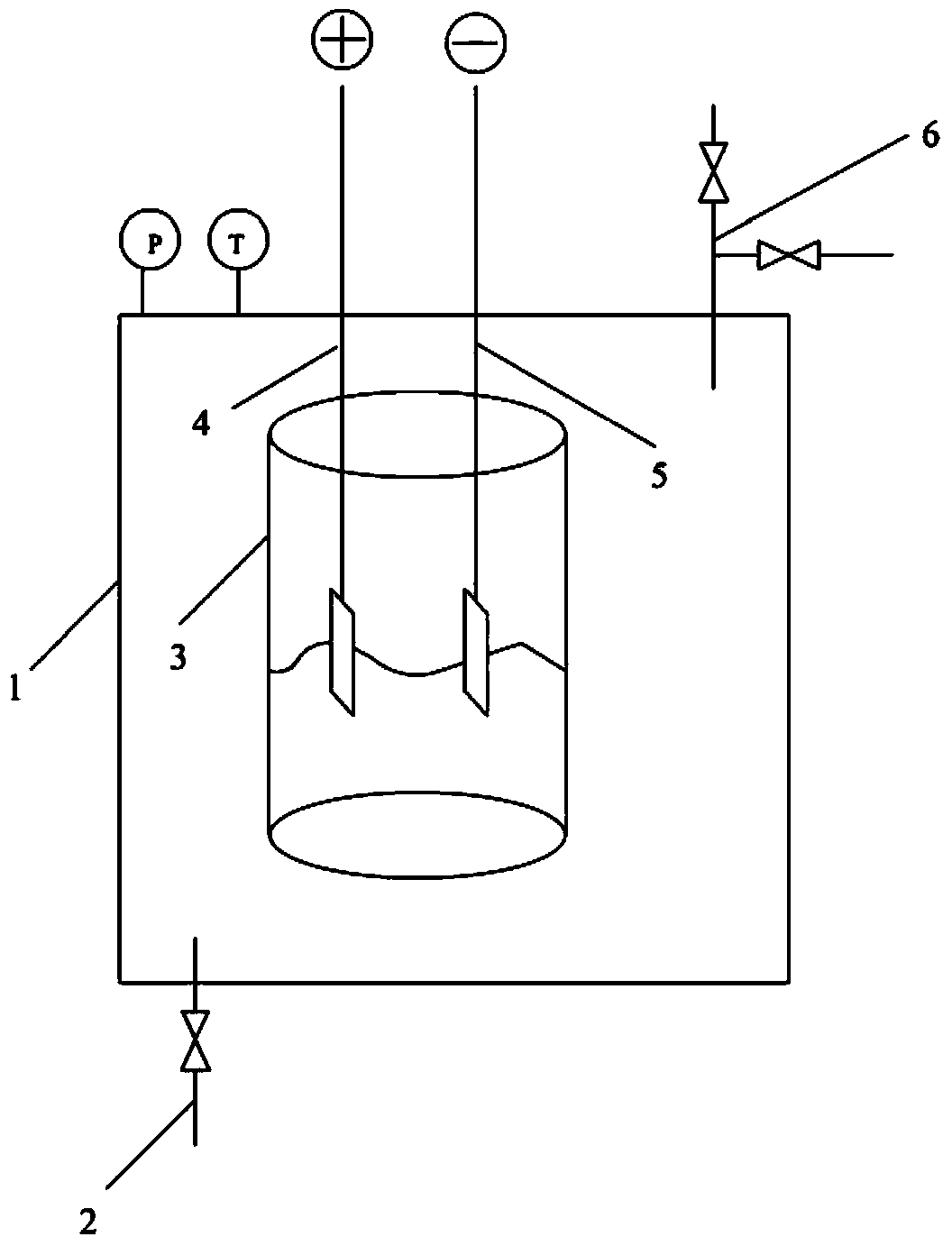

Method used

Image

Examples

Embodiment 1

[0047] The method for preparing nano-tungsten powder by recycling waste cemented carbide by molten salt electrolysis: the electrolytic cell is protected by 10% oxygen + argon (volume ratio) gas. The composition of the molten salt system is NaCl-52mol% CaCl 2 , the electrolysis temperature is 750°C, the metal titanium plate is used as the cathode, the YG6 type waste cemented carbide is used as the anode material, the pole distance is 3cm, the electrolysis voltage is controlled, the cell voltage is controlled at 3.2V, and the cell current is stable at 1.3A during the electrolysis process , with the consumption of anode material, the cell current increases. Electrolysis for 8 hours. The metal powder and molten salt medium obtained by electrolysis are separated and collected from the molten salt medium and the product powder by pickling, washing, filtering and vacuum drying. The vacuum degree is 0.5MPa, and the drying temperature is 50°C.

[0048] The purity of the tungsten met...

Embodiment 2

[0050] A method of using molten salt electrolysis to treat waste WC cemented carbide to directly recover WC powder powder: the electrolytic cell is protected by argon gas. The composition of the molten salt system is NaCl-50mol% KCl, the electrolysis temperature is 750°C, graphite carbon is used as the cathode, WC is the anode material, the pole distance is 3cm, the electrolysis current is controlled, and the electrolysis current density is controlled at 0.3A / cm 2 , The tank voltage is stable at 2.2V during the electrolysis process. The metal powder and molten salt medium obtained by electrolysis are separated and collected from the molten salt medium and product powder by pickling, water washing, filtration and vacuum drying. The vacuum degree is 0.5MPa, and the drying temperature is 50°C.

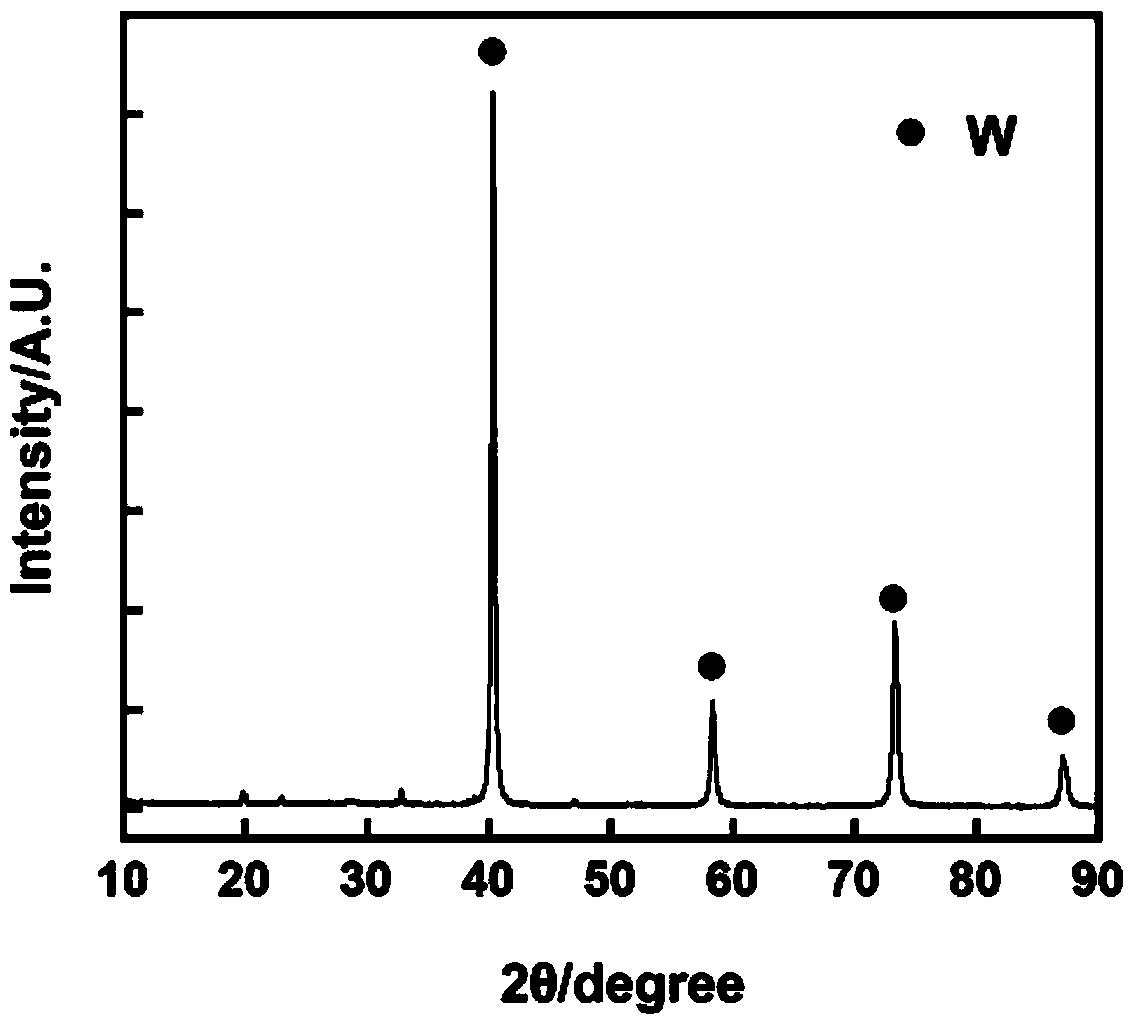

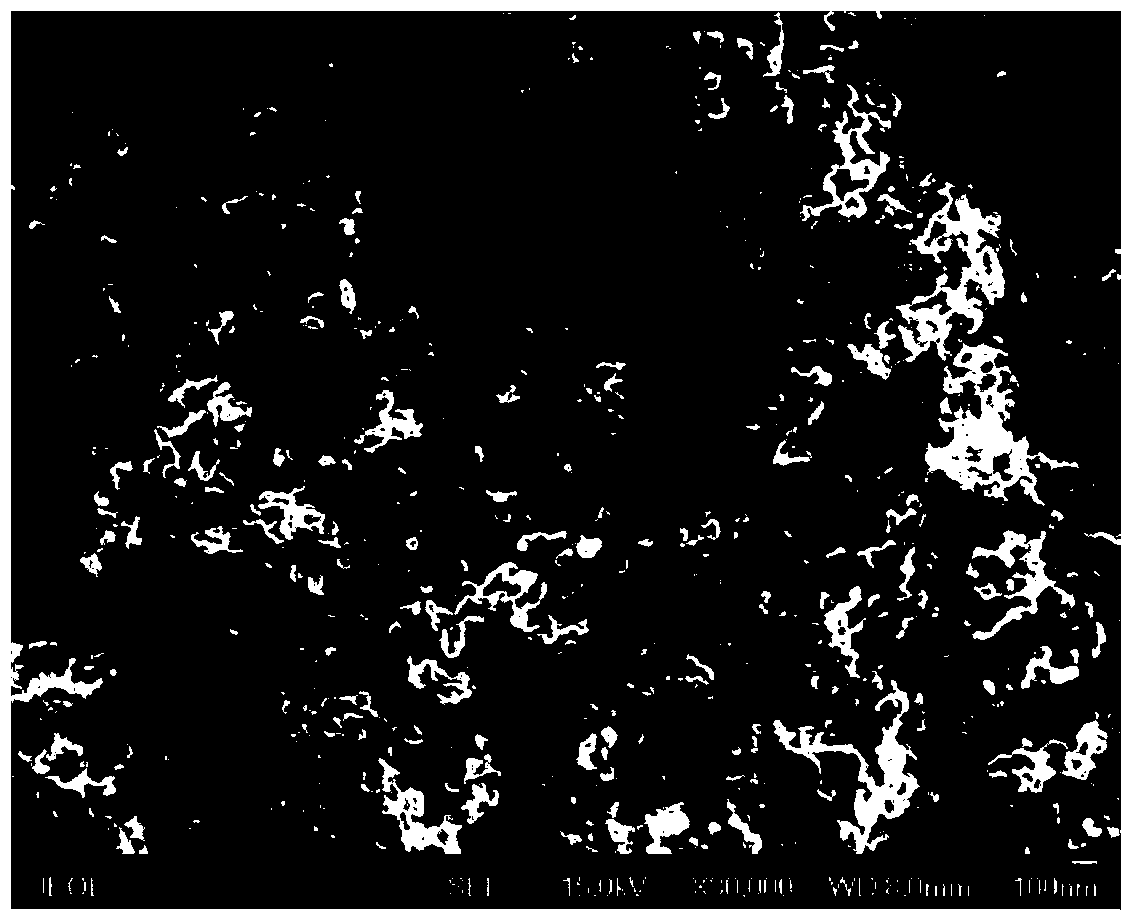

[0051] The WC powder particles were obtained by electrolysis, and its purity reached 99.1wt%. The XRD patterns and FESEM photos of the products are shown in Figure 4 , Figure 5 .

Embodiment 3

[0053] A method for directly preparing tungsten-cobalt alloy powder by using molten salt electrolysis of waste cemented carbide: the electrolytic tank is protected by a mixed gas of 20% oxygen and argon. The composition of the molten salt system is NaCl-50mol% Na 2 WO 4 -26mol% CaCl 2 , the electrolysis temperature is 750°C, the metal titanium plate is used as the cathode, the YG16 waste cemented carbide is used as the anode material, the pole distance is 3cm, the electrolysis current is controlled, and the electrolysis current density is controlled at 0.5A / cm 2 , The tank voltage is stable at 2.9V during the electrolysis process. Electrolysis to obtain W-Co composite powder particles. The metal powder and molten salt medium obtained by electrolysis are separated and collected from the molten salt medium and product powder by pickling, water washing, filtration and vacuum drying. The vacuum degree is 0.5MPa, and the drying temperature is 40°C.

[0054] The XRD patterns an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com