Fluorescence carbon quantum dots, and preparation method and application thereof

A carbon quantum dot and fluorescence technology, applied in the field of luminescent nanomaterials, can solve the problems of high cost, low fluorescence quantum yield, unfavorable continuous and large-scale production of carbon quantum dots, etc., and achieves convenient operation, wide source of raw materials, and quantum yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1, weighing 1g of chitosan in a microwave-resistant container, then adding 10mL of 8% glacial acetic acid and 5mL of ethylenediamine solution, fully stirring to obtain a paste;

[0030] Step 2, the microwave-resistant container is placed in a microwave oven (700 watts) and reacted for 15 minutes under high heat to obtain a black solid;

[0031] Step 3, take out the microwave-resistant container, cool naturally, add 20mL of secondary water to it, stir and dissolve to obtain a brown solution, filter to remove insoluble matter to obtain a clear brown solution, remove impurities by dialysis, and obtain a pure aqueous solution of fluorescent carbon quantum dots ;

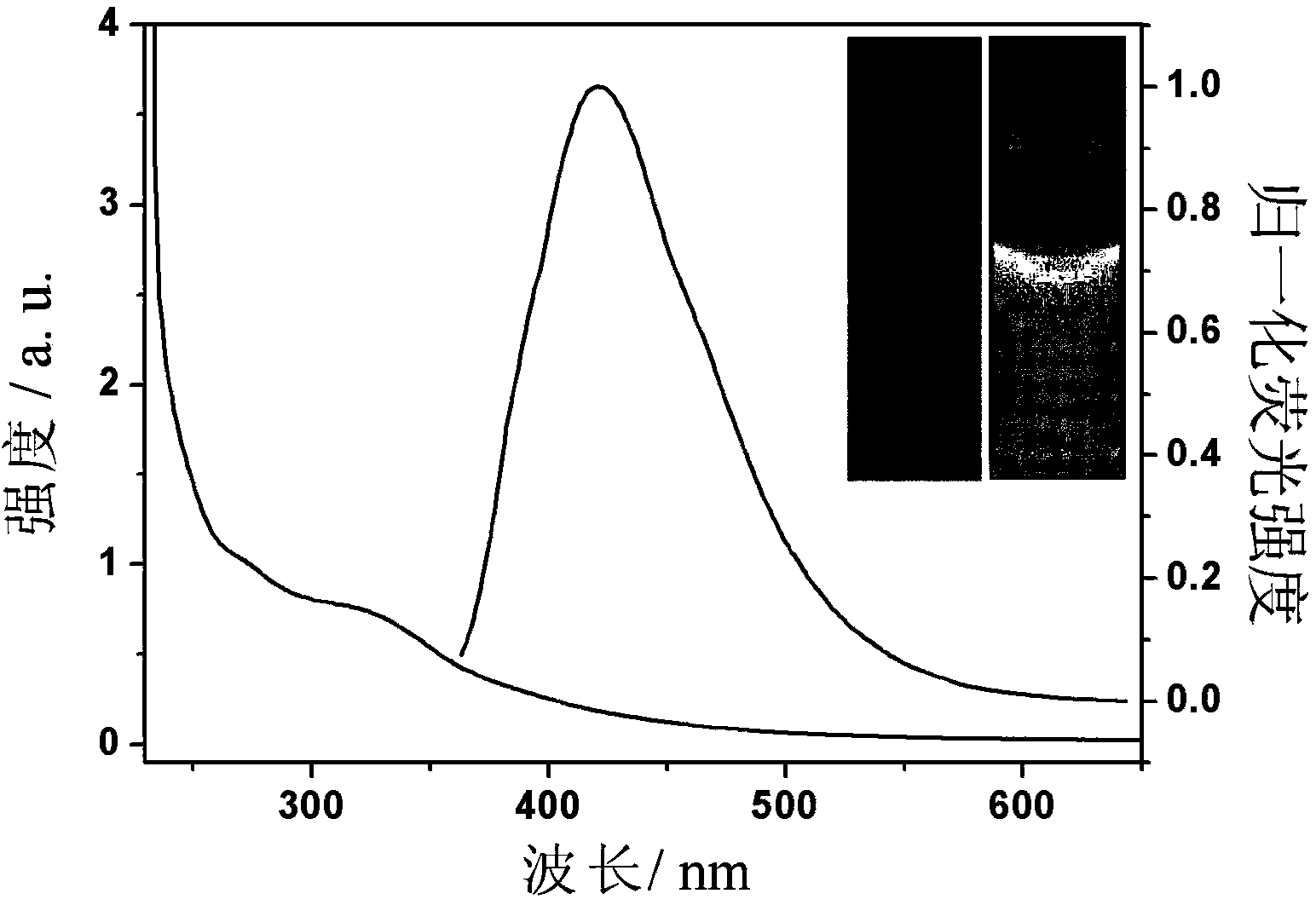

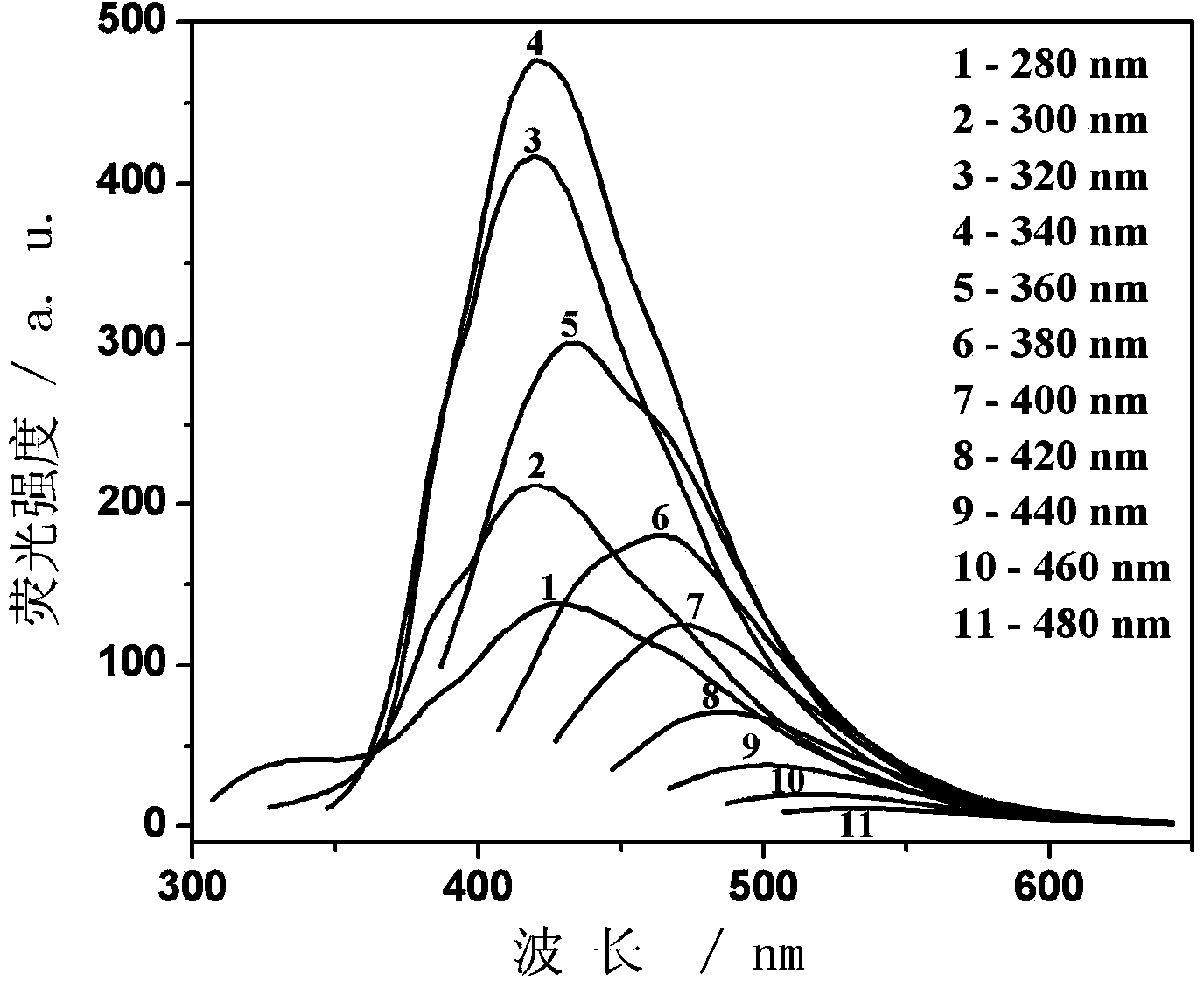

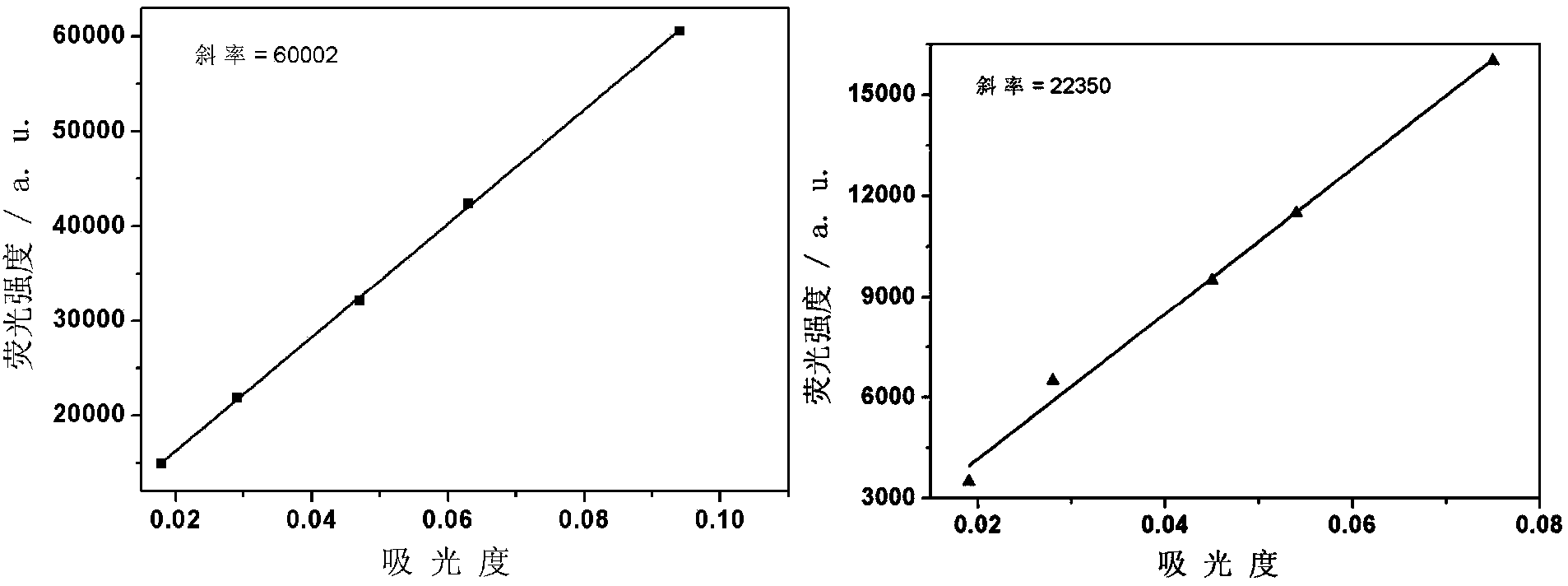

[0032] In step 4, the fluorescent carbon quantum dot aqueous solution is freeze-dried to obtain the fluorescent carbon quantum dot, and its relative quantum yield (taking quinine sulfate as a standard) is 19.5%.

[0033] Characterization and application see Figure 1-10 .

Embodiment 2

[0035] Step 1, weighing 2g of chitosan in a microwave-resistant container, then adding 20mL of 4% glacial acetic acid and 10mL of ethylenediamine solution, fully stirring to obtain a paste;

[0036] Step 2, the microwave-resistant container was placed in a microwave oven (700 watts) and reacted for 17 minutes at high heat to obtain a black solid;

[0037] Step 3, take out the microwave-resistant container, cool it naturally, add 40mL of secondary water to it, stir and dissolve to obtain a brown solution, filter and remove insoluble matter to obtain a clear brown solution, remove impurities by dialysis, and obtain a pure aqueous solution of fluorescent carbon quantum dots ;

[0038] In step 4, the above-mentioned fluorescent carbon quantum dot aqueous solution is freeze-dried to obtain high fluorescent quantum yield carbon quantum dots, and its relative quantum yield (taking quinine sulfate as a standard) is 16.6%.

Embodiment 3

[0040] Step 1, weighing 1g of chitosan in a microwave-resistant container, then adding 8mL of 8% glacial acetic acid and 7mL of ethylenediamine solution, fully stirring to obtain a paste;

[0041] Step 2, the microwave-resistant container is placed in a microwave oven (700 watts) and reacted for 12 minutes under high heat to obtain a black solid;

[0042] Step 3, take out the microwave-resistant container, cool naturally, add 20mL of secondary water to it, stir and dissolve to obtain a brown solution, filter to remove insoluble matter to obtain a clear brown solution, remove impurities by dialysis, and obtain a pure aqueous solution of fluorescent carbon quantum dots ;

[0043] In step 4, the above-mentioned fluorescent carbon quantum dot aqueous solution is freeze-dried to obtain high fluorescent quantum yield carbon quantum dots, and its relative quantum yield (taking quinine sulfate as a standard) is 17.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com