A method of nickel-plating on the surface of electric discharge machining of electronic packaging aluminum-based composite materials

An aluminum-based composite material and electronic packaging technology, which is applied in the field of electroless nickel plating, can solve the problems of weak bonding between the coating and the substrate, increase processing procedures and costs, and achieve good surface quality of the coating, good bonding, and small influencing factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

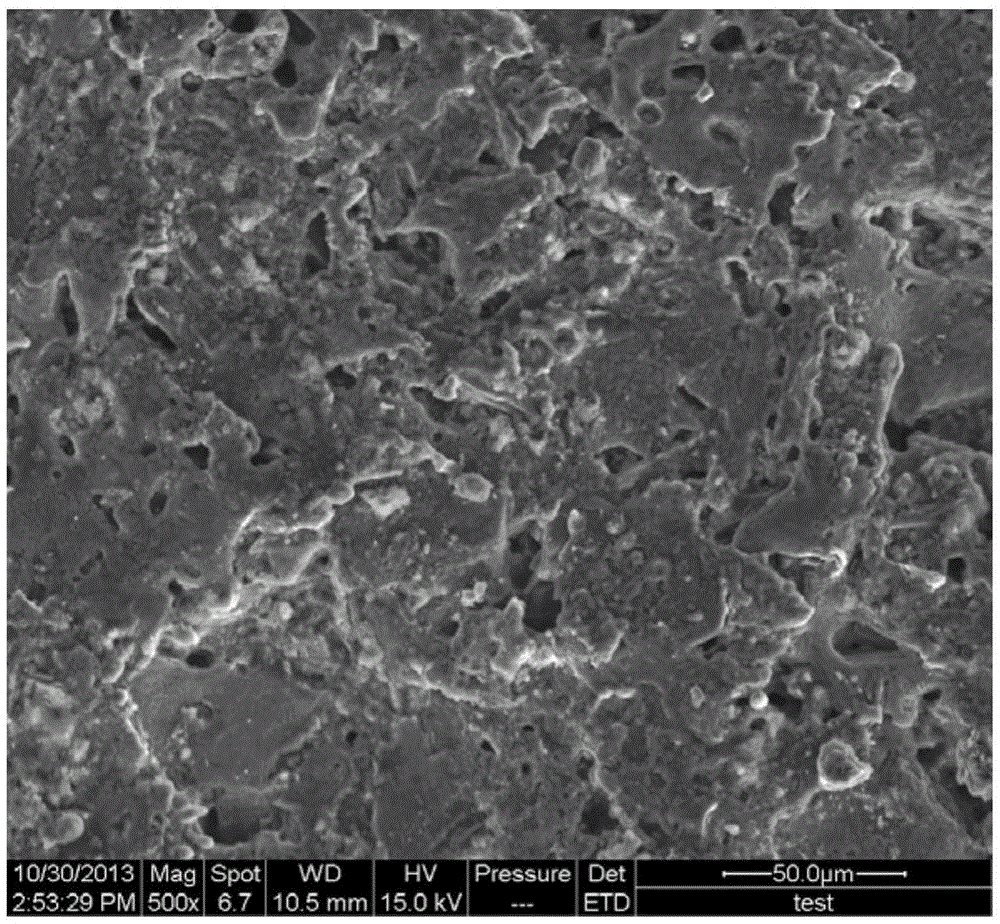

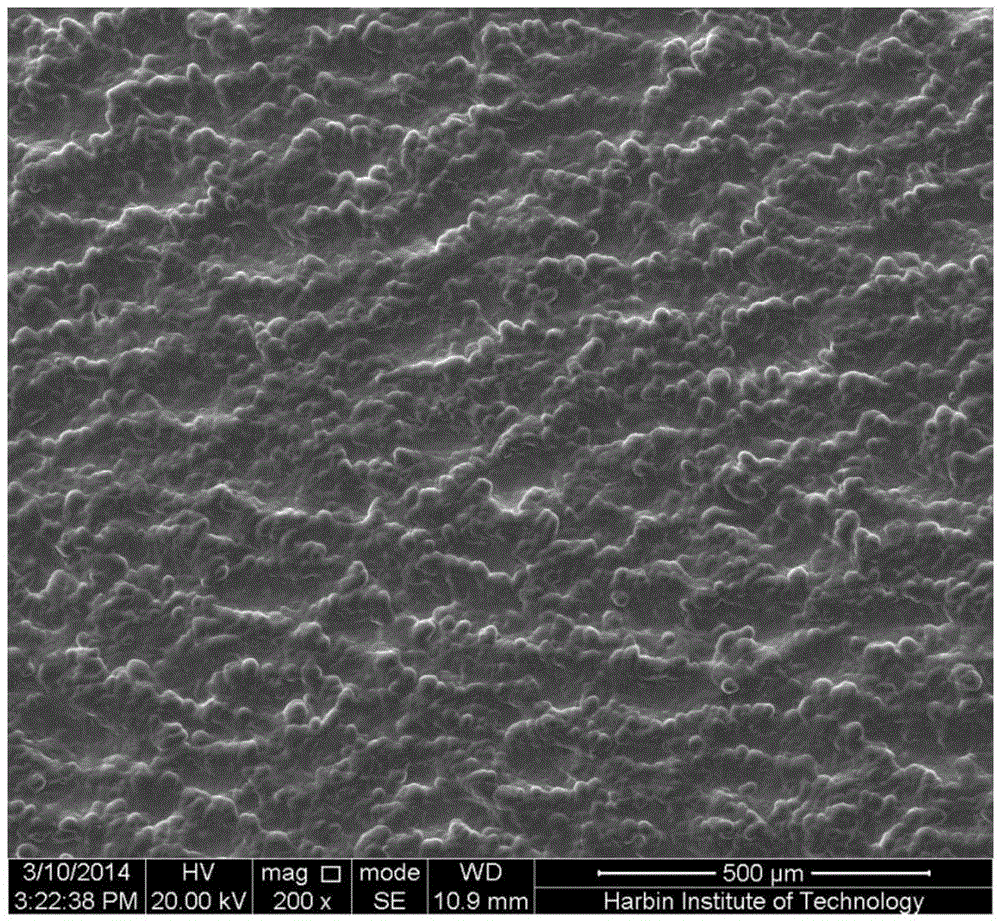

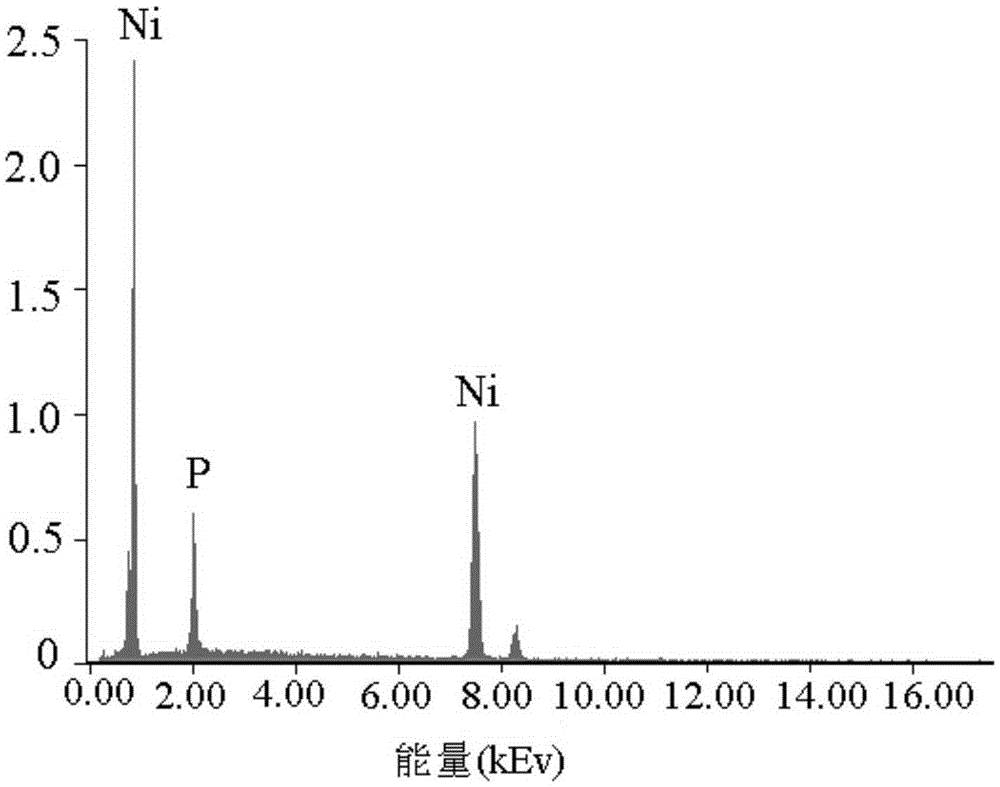

[0037] Specific implementation mode 1: This implementation mode is a method for plating a nickel layer on the surface of electronic packaging aluminum-based composite materials by electrical discharge machining, which is specifically completed according to the following steps:

[0038] 1. Cleaning: First, immerse the electronic packaging aluminum matrix composite material processed by EDM into an ultrasonic cleaner filled with acetone, and ultrasonically clean it for 15min to 20min under the condition of a power of 250W~300W; then replace the ultrasonic cleaner acetone, ultrasonically cleaned for 10min to 15min at a power of 250W to 300W, and then cleaned with deionized water for 1 to 3 times to obtain the cleaned aluminum matrix composite material for electronic packaging processed by EDM;

[0039] 2. Acid etching: Soak the cleaned aluminum-based composite material for electronic packaging processed by EDM in nitric acid solution for 48s~52s, take it out and wash it with deion...

specific Embodiment approach 2

[0062] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the aluminum-based composite material for electronic packaging described in Step 1 is SiC with a volume fraction of SiC particles of 65%. p / Al composites. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0063] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, the electronic packaging aluminum-based composite material processed by EDM is first immersed in an ultrasonic cleaning machine equipped with acetone. Ultrasonic cleaning at 300W for 20 minutes; then replace the acetone in the ultrasonic cleaning machine, ultrasonically clean at 300W for 15 minutes, and then use deionized water to clean 2 to 3 times to obtain the cleaned EDM Aluminum matrix composites for electronic packaging. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com