High-moisture admixture cement grinding aid and preparation method thereof

A technology for cement grinding aids and admixtures, applied in the field of grinding aids, can solve the problems of limited utilization of admixtures, decreased yield, and reduced strength, etc., achieves strong surface activity, reduces power consumption for grinding, and eliminates adhesion and aggregation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: a kind of high-moisture admixture cement grinding aid, composition is as follows:

[0021] Polypolyol Grinding Aid Mother Liquor 40%

[0022] Acrylic acid 0.01%

[0024] Sodium dodecylbenzenesulfonate 0.02%

[0025] Triethanolamine 2%

[0026] Sugarcane sugar residue liquid 1%

[0027] The balance is water, and the total amount is 100%.

[0028] Among them, the preparation method of the polypolyol grinding aid mother liquor is as follows: In a reaction pot, add 2 parts of maleic anhydride and 1 part of polypolyol and mix evenly, and react at 90-110 °C for 2-4 hours to synthesize polypolyol grinding aid. Abrasive mother liquor. Most preferably, react at 100°C for 3h.

[0029] The preparation method of high-moisture mixture cement grinding aid, the steps are: control the temperature of the prepared polypolyol grinding aid mother liquor to below 60°C, add water, acrylic acid, and ammonium sulfate to react for 20-40 minutes ...

Embodiment 2 to Embodiment 5

[0034] Repeat the method of Experimental Example 1 according to the content of each component specified in the following table 1, and obtain the high-moisture admixture cement grinding aid product 2 to product 5 of different component content respectively:

[0035] Table 1

[0036] Component (%)

Example 1

Example 2

Example 3

Example 4

Example 5

Polyol Grinding Aid Mother Liquor

40

45

50

40

55

[0037] acrylic

0.01

0.1

0.2

0.4

0.5

ammonium sulfate

1

3

5

8

10

Sodium dodecyl benzene sulfonate

0.02

0.03

0.04

0.02

0.05

2

3

4

5

2

1

2

3

4

5

get

Product 1

Product 2

Product 3

Product 4

Product 5

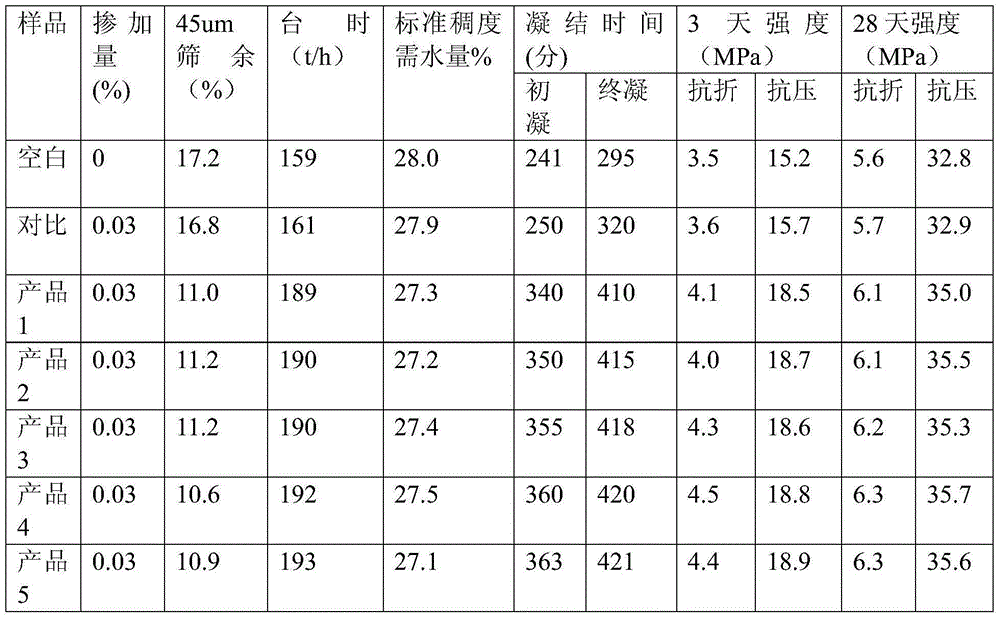

[0038] With the high-moisture admixture cement grinding aid product obtained in embodiment 1 to embodiment 5, the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com