High energy ball milling process-containing preparation method for nanometer multi-element composite crystal grain growth inhibitor

A multi-component composite and grain growth technology, applied in the field of cemented carbide preparation, can solve the problems of shortened production cycle, narrow selection of raw materials, long sintering time, etc., and achieve the effect of convenient industrial production, low equipment requirements and stable supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

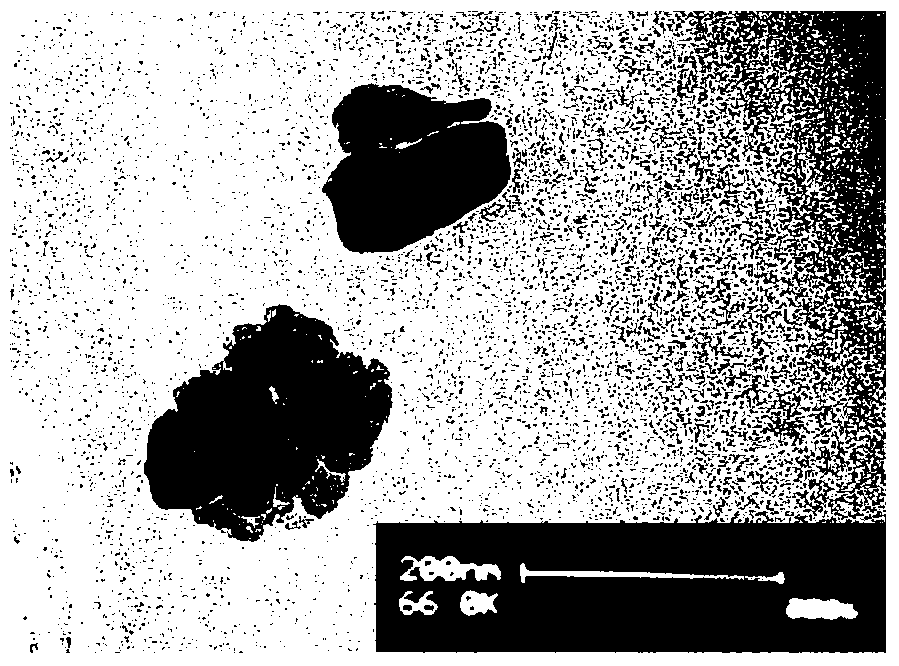

Image

Examples

Embodiment 1

[0034] In the present embodiment, the chemical formula of the prepared nano multi-component composite grain growth inhibitor is (V 0.8 ,Cr 0.2 )(C 0.5 ,N 0.5), the structure is a vanadium carbonitride-based solid solution containing solid solution metal chromium, and the process steps are as follows:

[0035] (1) Ingredients

[0036] According to the chemical formula (V 0.8 ,Cr 0.2 )(C 0.5 ,N 0.5 ), select the raw materials of components other than nitrogen, and measure each raw material selected according to the molar number of components other than nitrogen in the chemical formula to carry out batching, and the weight percentage of each raw material is as follows:

[0037] Vanadium pentoxide: 59.84%

[0038] Chromium trioxide: 12.50%

[0039] Nano carbon black: 27.66%;

[0040] (2) High energy ball mill

[0041] The raw materials prepared in step (1) were dry-milled for 16 hours with a high-energy ball mill at a speed of 450 rpm to obtain a ball mill powder, where...

Embodiment 2

[0045] In the present embodiment, the chemical formula of the prepared nano multi-component composite grain growth inhibitor is (V 0.6 ,Cr 0.4 )(C 0.5 ,N 0.5 ), the structure is a vanadium carbonitride-based solid solution containing solid solution metal chromium, and the process steps are as follows:

[0046] (1) Ingredients

[0047] According to the chemical formula (V 0.6 ,Cr 0.4 )(C 0.5 ,N 0.5 ), select the raw materials of components other than nitrogen, and measure each raw material selected according to the molar number of components other than nitrogen in the chemical formula to carry out batching, and the weight percentage of each raw material is as follows:

[0048] Vanadium pentoxide: 54.90%

[0049] Chromium powder: 20.93%

[0050] Carbon black: 24.17%;

[0051] (2) High energy ball mill

[0052] The raw materials prepared in step (1) were dry-milled for 6 hours with a high-energy ball mill at a speed of 700 rpm to obtain a ball-mill powder with a weight...

Embodiment 3

[0056] In the present embodiment, the chemical formula of the prepared nano multi-component composite grain growth inhibitor is (V 0.95 , Ti 0.05 )(C 0.5 ,N 0.5 ), the structure is a vanadium carbonitride-based solid solution containing solid solution metal titanium, and the process steps are as follows:

[0057] (1) Ingredients

[0058] According to the chemical formula (V 0.95 , Ti 0.05 )(C 0.5 ,N 0.5 ), select the raw materials of components other than nitrogen, and measure each raw material selected according to the molar number of components other than nitrogen in the chemical formula to carry out batching, and the weight percentage of each raw material is as follows:

[0059] Vanadium pentoxide: 50.98%

[0060] Vanadium powder: 20.77%

[0061] Nano titanium dioxide: 4.07%

[0062] Activated carbon: 24.18%;

[0063] (2) High energy ball mill

[0064] The raw materials prepared in step (1) were dry-milled for 30 hours with a high-energy ball mill at a speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com