Photoresist remover

A stripper and photoresist technology, applied in the field of photolithography, can solve problems such as wiring corrosion, and achieve the effects of excellent corrosion resistance and excellent peelability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

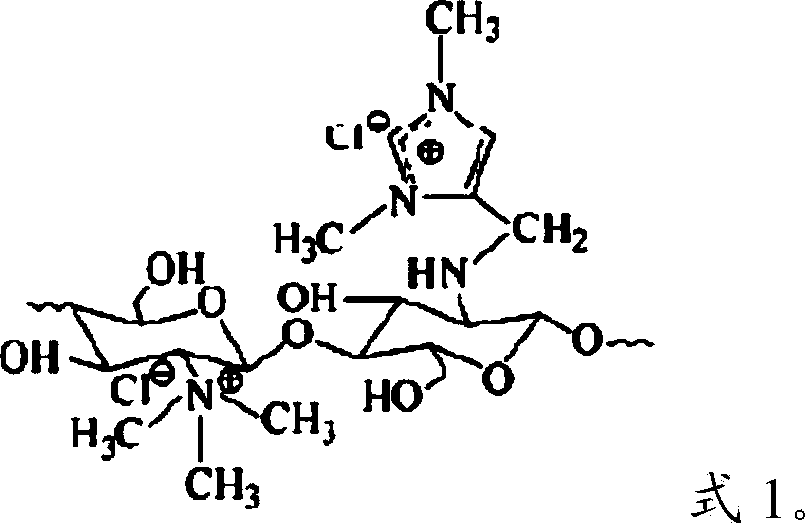

[0041] The preparation method of the modified chitosan is specifically:

[0042]In the first step, weigh 2.0g of chitosan in 40mL of distilled water, stir and swell overnight, adjust the pH of the system to 4-5 with dilute acetic acid solution, add 0.60g of 4-imidazole formaldehyde, and react at 95°C for 10h. Adjust the pH to neutral with dilute NaOH solution, and use NaBH 4 Reduction, the product is precipitated in acetone solution, filtered and washed with 90% ethanol until neutral, then extracted with absolute ethanol for 48 hours, and vacuum-dried at 45°C to obtain an intermediate product;

[0043] In the second step, 1.0 g of the intermediate product was weighed and added to 40 mL of NMP solution, and stirred and swelled overnight. Add 2.4g NaI and 6mL15% NaOH solution, stir at 60°C for 20min, then add 6mL CH 3 I, reaction 2h. Then add 3 mL of 15% NaOH solution and 3 mL of CH 3 1, continue to react for 2h. Pour into ethanol / ether (volume ratio=1:1), filter and wash w...

Embodiment 1

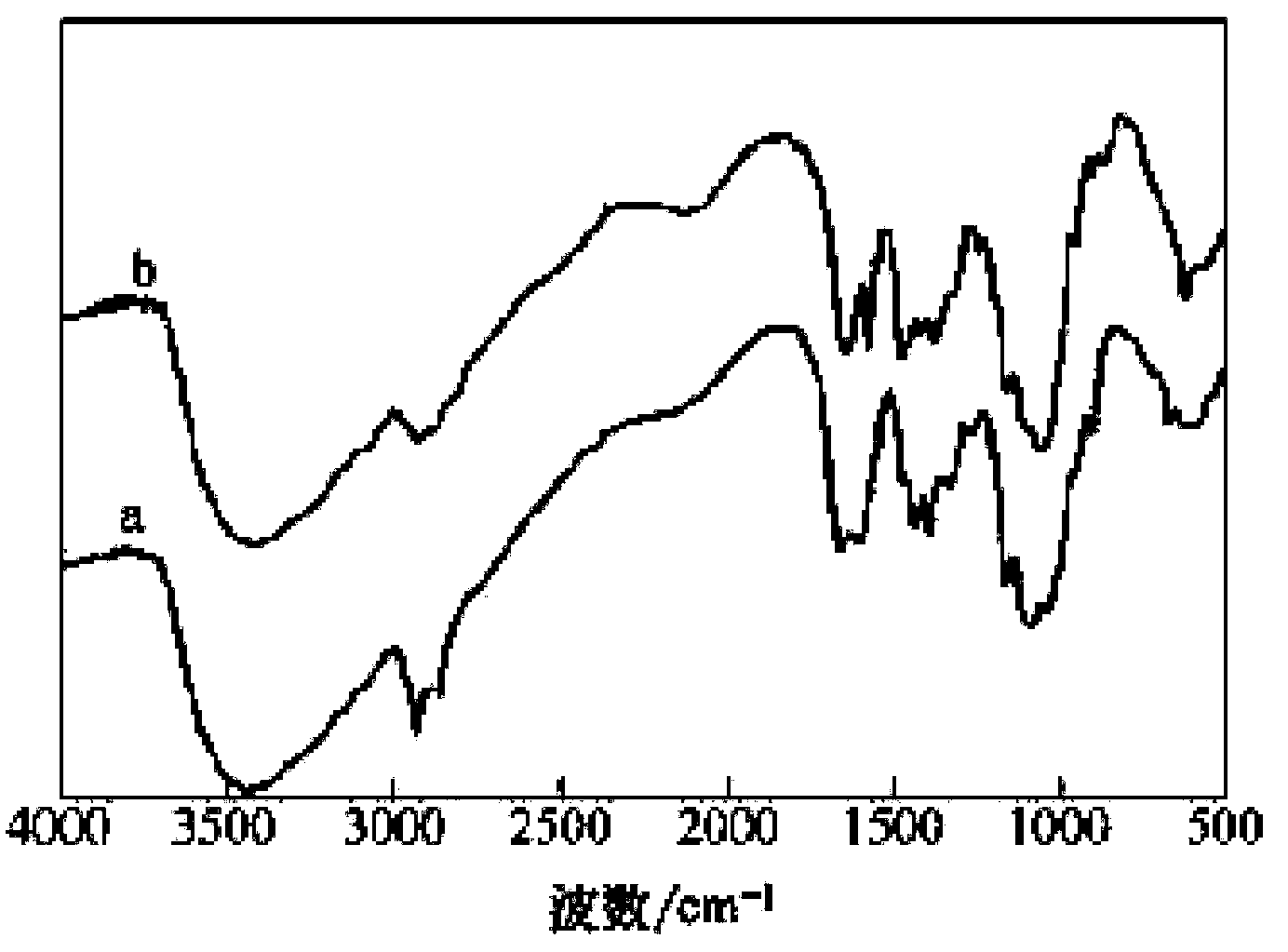

[0060] The preparation of the modified chitosan of embodiment 1

[0061] Weigh 2.0g of chitosan in 40mL of distilled water, stir and swell overnight, adjust the pH of the system to 4-5 with dilute acetic acid solution, add 0.60g of 4-imidazole formaldehyde, and react at 95°C for 10h. Adjust the pH to neutral with dilute NaOH solution, and use NaBH 4 Reduction, the product is precipitated in acetone solution, filtered and washed with 90% ethanol to neutrality, then extracted with absolute ethanol for 48 hours, and vacuum-dried at 45°C to obtain the intermediate product, weigh 1.0g of the intermediate product and add 40mL of NMP solution , stirred and swelled overnight. Add 2.4gNaI and 6mL15% NaOH solution, stir at 60°C for 20min, then add 6mL CH 3 I, reaction 2h. Then add 3 mL of 15% NaOH solution and 3 mL of CH 3 1, continue to react for 2h. Pour into ethanol / ether (volume ratio=1:1), filter and wash with ether. Dialyze with NaCl solution and distilled water (molecular w...

Embodiment 2

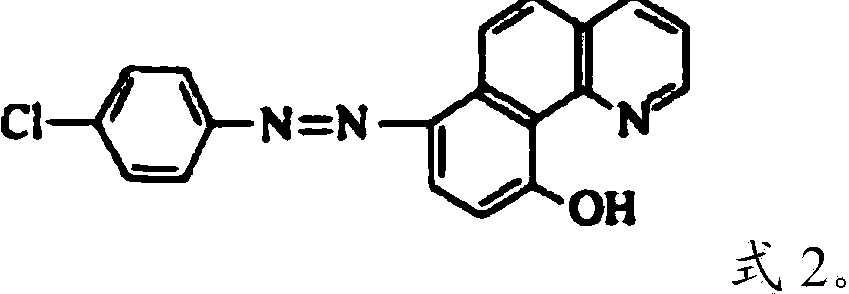

[0064] The preparation of embodiment 2 benzoquinoline compounds

[0065] Add 2.0 g of p-chloroaniline to 5 ml of distilled water and 5 ml of 37% concentrated hydrochloric acid, stir at room temperature for 30 minutes, filter the crystals and wash with ethanol for 3 times, and dry to obtain 1.98 g of solid, which is p-chloroaniline hydrochloride; Dissolve 0.72g of p-chloroaniline hydrochloride in 5ml of distilled water and 5ml of 37% concentrated hydrochloric acid, cool to 0-5°C (ice-water bath), slowly add NaNO dropwise 2 Aqueous solution (0.5g NaNO 2 dissolved in 10ml of water), until the starch potassium iodide test paper just turns blue, maintain 0-5 ℃ and continue to react for 30min; take 0.5g of 10-hydroxybenzoquinoline (HBQ), dissolve in 10ml of distilled water and 10ml of dioxane In the mixed solution, keep 0-5°C, adjust the system to pH = 8 with sodium hydroxide, slowly add the 10-hydroxybenzoquinoline solution to the product obtained in the second step under vigorous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com