Method for preparing nano TiO2

A nano, aqueous solution technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, titanium oxide/hydroxide, etc., can solve the problems of waste of resources, environmental pollution of waste water, environmental pollution, etc. Achieve the effect of reducing water and energy consumption, good suspension performance and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

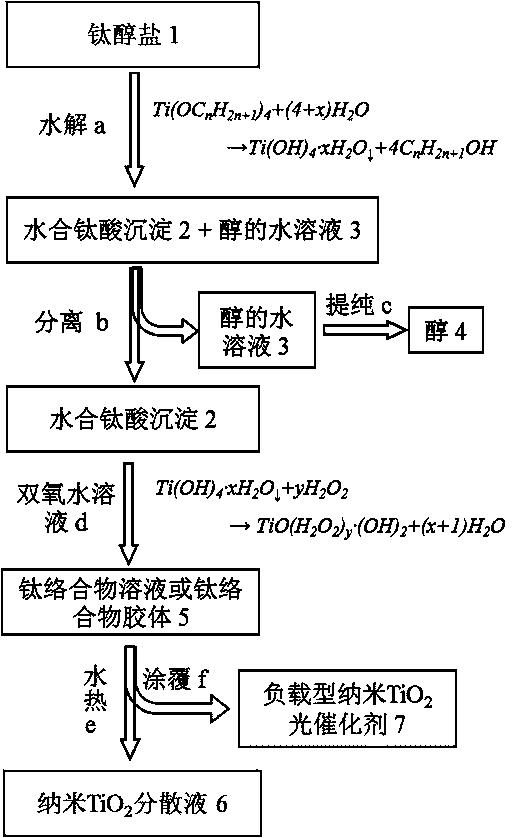

[0050] Such as figure 1 As shown, under stirring at normal temperature and pressure, 5 ml of titanium isopropoxide was slowly added dropwise to 20 ml of pure water to obtain a white hydrated titanic acid precipitate suspension. After standing still for 1 hour, the hydrated titanic acid precipitate was separated by filtration to obtain a hydrated titanic acid precipitate and a clear aqueous solution of isopropanol. At this point, the aqueous solution of isopropanol can be directly recovered. Add 200 ml of 3% hydrogen peroxide aqueous solution to the separated hydrated titanic acid precipitate, and stir for 2 hours to form a titanium complex aqueous solution. Take the above-mentioned 80 milliliters of titanium complex aqueous solution in a 100 milliliter hydrothermal kettle, and react hydrothermally at 110 degrees Celsius for 4 hours to obtain nano-TiO with small particle size, high crystallinity, monodisperse and suspended anatase phase. 2 Dispersions. The above-mentioned is...

Embodiment 2

[0054] Under normal temperature and pressure stirring, 5 ml of tetrabutyl titanate was slowly added dropwise to 20 ml of pure water to obtain white hydrated titanic acid precipitate. After standing still for 1 hour, the hydrated titanic acid precipitate was separated by filtration to obtain hydrated titanic acid precipitate and n-butanol aqueous solution. Add 200 ml of 4% hydrogen peroxide aqueous solution to the separated hydrated titanic acid precipitate, and stir for 3 hours to form a titanium complex aqueous solution. Take the above-mentioned 80 ml titanium complex aqueous solution in a 100 ml hydrothermal kettle, and conduct a hydrothermal reaction at 120 degrees Celsius for 3 hours to obtain a small particle size, high crystallinity, monodisperse, suspended anatase phase nano-TiO 2 Dispersions. The n-butanol in the above-mentioned n-butanol aqueous solution was purified by a method combining liquid separation and distillation to obtain n-butanol with a concentration of ...

Embodiment 3

[0056] Under stirring at normal temperature and pressure, 5 ml of titanium isopropoxide was slowly added dropwise to 20 ml of pure water to obtain a white hydrated titanic acid precipitate. After standing still for 1 hour, the hydrated titanic acid precipitate was separated by filtration to obtain a hydrated titanic acid precipitate and a clear isopropanol aqueous solution. Add 200 ml of 3% hydrogen peroxide aqueous solution to the separated hydrated titanic acid precipitate, and stir for 2 hours to form a titanium complex aqueous solution. Take the above-mentioned small amount of titanium complex aqueous solution and spray it on the silicon wafer, after natural drying, anneal treatment at 200 degrees Celsius for 2 hours to obtain nano-TiO supported on the silicon wafer. 2 catalyst of light. The above-mentioned isopropanol aqueous solution is heated and distilled, and purified to obtain high-concentration isopropanol.

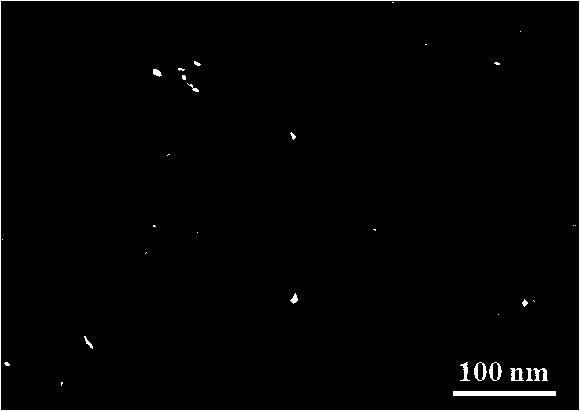

[0057] Please refer to Figure 5 , it can be seen that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com