Preparation method of magnetic precious metal heterogeneous catalyst

A technology of heterogeneous catalyst and precious metal catalyst is applied in the field of preparation of magnetic precious metal heterogeneous catalyst, which can solve the problems of complicated centrifugal and filtration recovery methods, limited separation efficiency, complicated operation and the like, and achieves low cost, low equipment requirements, Choose from a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation method of magnetic carrier

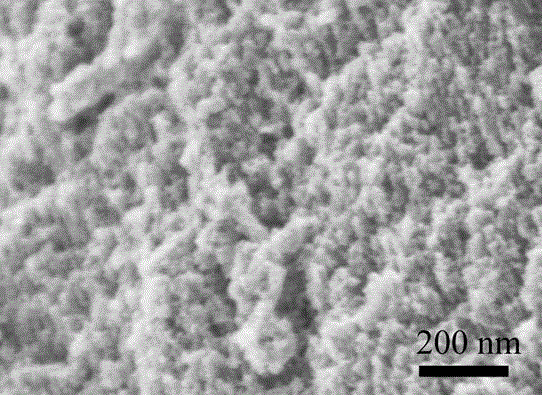

[0030] At room temperature, add 1.0 g activated carbon, 0.5 g FeSO 4 ·7H 2 O, 0.25g NiSO 4 ·6H 2 O, 250mL deionized water, mechanically stirred at a rate of 220r / min to dissolve it, and N 2 Exhaust the air in the system, and then add 10 mL of dissolved 0.12 g NaBH dropwise while stirring 4 deionized aqueous solution. After reacting for 30 minutes, the black suspension was separated magnetically, the solution was poured off, the solution was washed with deionized water, and the above product was vacuum-dried for 2 hours to obtain a magnetic carbon carrier. figure 1 SEM photographs of magnetic carbon carriers.

[0031] The corresponding carbon carrier can be obtained by replacing the activated carbon with alumina, kaolin, diatomaceous earth, etc.

Embodiment 2

[0033] Preparation method of magnetic palladium carbon (5% palladium content)

[0034] Add 0.2g of activated carbon and 0.1g of FeSO to a 250mL three-neck flask 4 ·7H 2 O, 0.05g NiSO 4 ·6H 2 O, 20mL of methanol and 30mL of deoxygenated water, mechanically stirred at a rate of 220r / min to dissolve, while passing through N 2 Exhaust the air in the system, and add 10mL of dissolved 0.04g NaBH dropwise while stirring 4 deoxygenated aqueous solution. Obtain black suspension, increase N 2 flow, let stand for 1 hour. Afterwards, increase the speed to 500r / min, and add 0.03g Na dissolved in it dropwise while stirring. 2 PdCl 4After the dropwise addition, the reaction was continued for 30 minutes to stop. The product was subjected to magnetic separation, washed with deoxygenated water and ethanol, and vacuum-dried for 2 h to obtain a magnetic palladium-carbon catalyst.

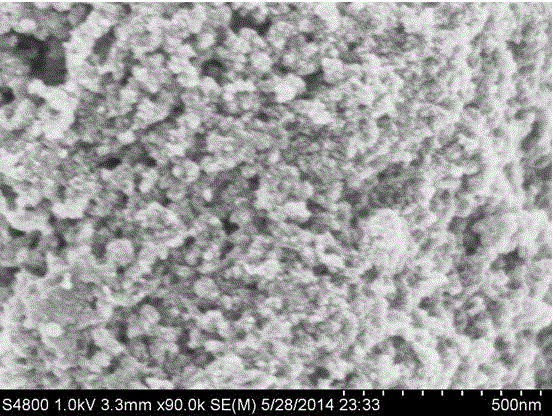

[0035] figure 2 It is a SEM photo of the magnetic palladium-carbon catalyst. It can be seen from the fig...

Embodiment 3

[0037] Preparation method of magnetic platinum carbon

[0038] Adopt the processing method of example 2, Na 2 PdCl 4 Replaced with Na 2 PtCl 4 Magnetic platinum-carbon catalysts can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com