Sandwiched parallel connection type epitaxy GaN PIN type beta irradiation battery and preparation method thereof

A parallel and epitaxial technology, applied in the field of microelectronics, can solve the problems of large device leakage current, low energy conversion rate, easy introduction of surface defects, etc., and achieve the effect of increasing the working voltage, increasing the energy conversion rate, and improving the energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

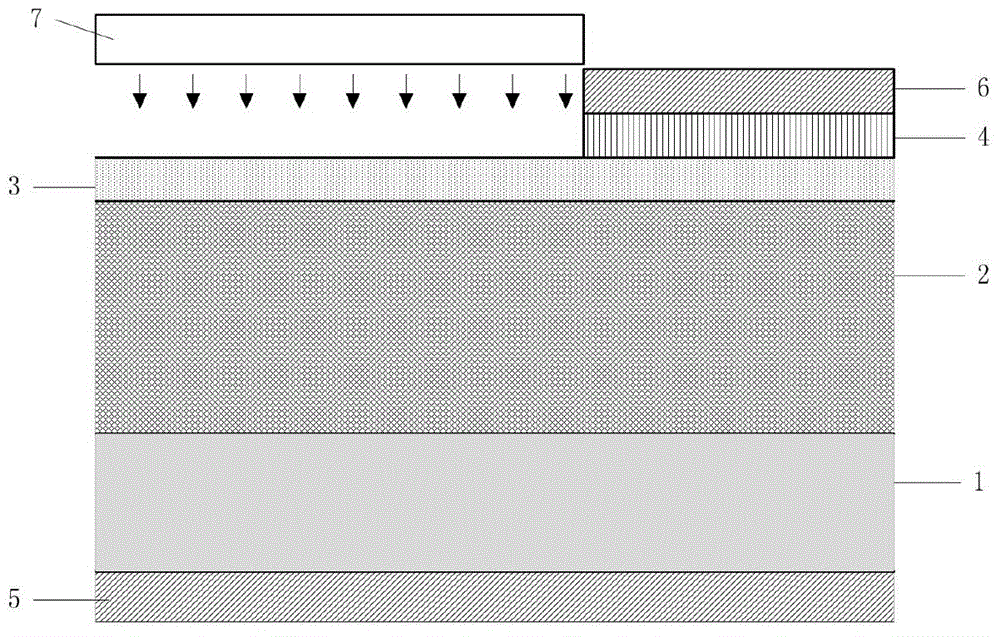

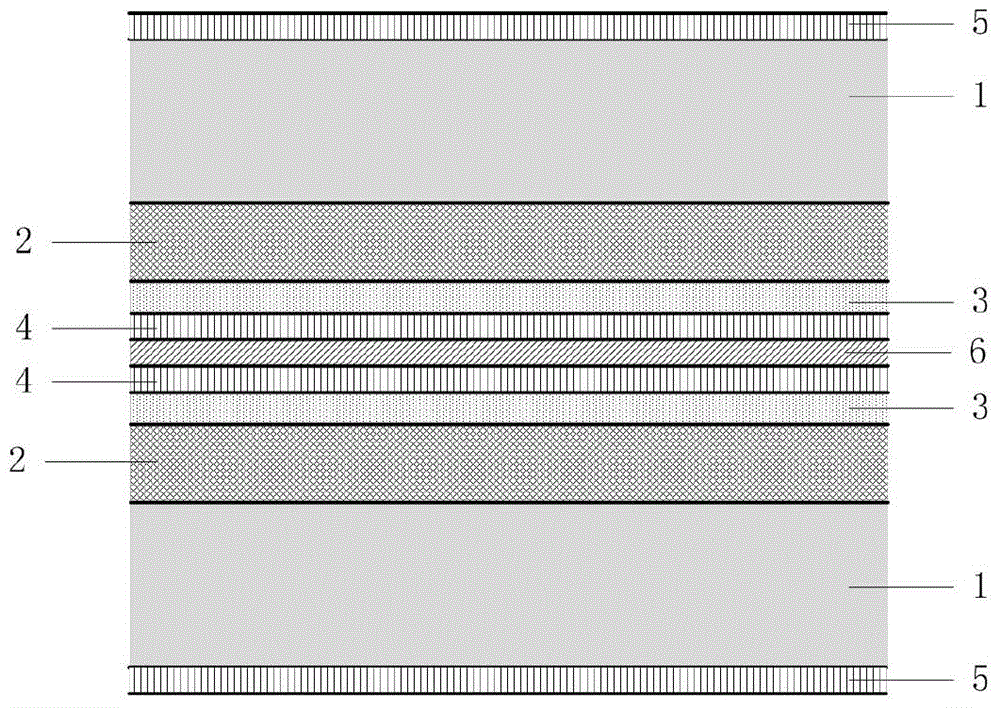

[0041] Embodiment 1, preparation β radiation source is Ni 63 , PIN-type β-irradiated cells with sandwich parallel epitaxial GaN with a β-radiation source layer thickness of 7 μm.

[0042] Step 1: Make the lower PIN knot.

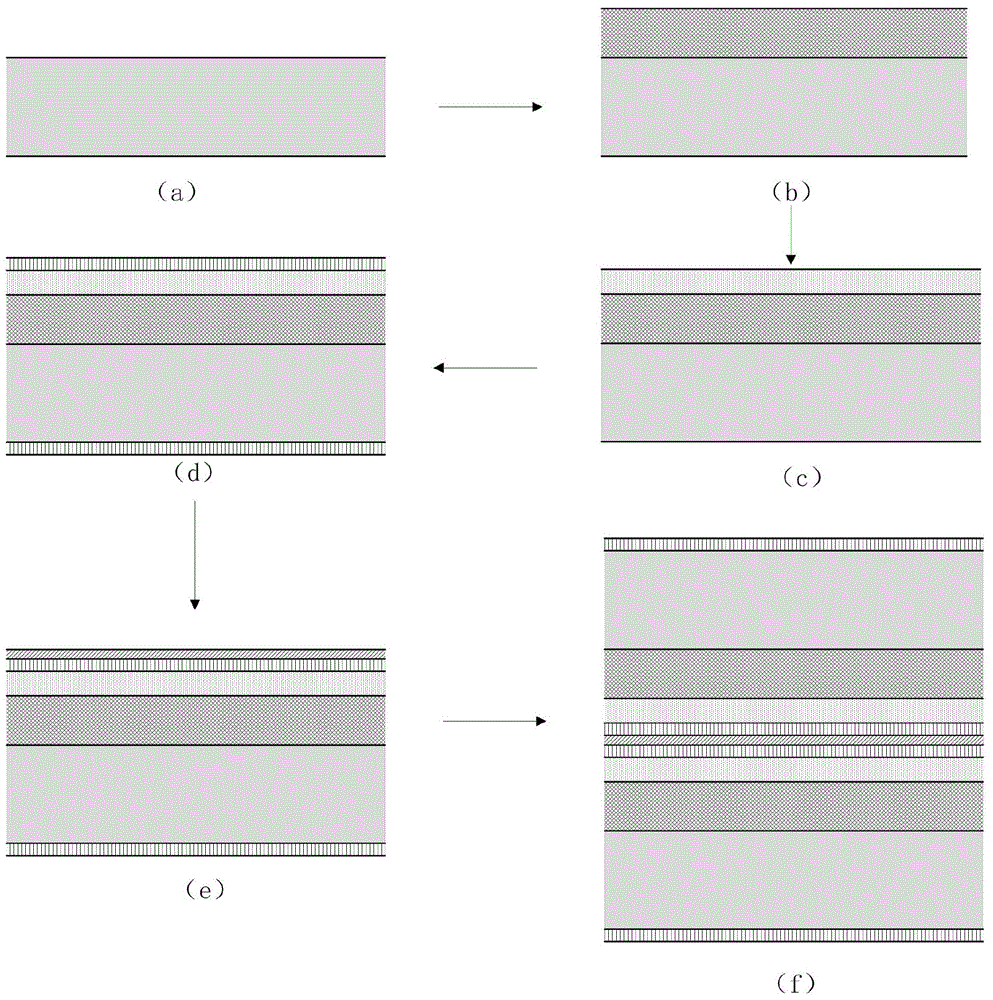

[0043] (1a) Clean the 4H-SiC sample to remove surface contaminants, such as image 3 (a) shown.

[0044] (1a.1) Set the doping concentration to l x10 18 cm -3 Highly doped n-type 4H-SiC substrate sample in NH 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample;

[0045] (1a.2) Use HCl+H to remove the 4H-SiC sample after removing the surface organic residues 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove ionic pollutants.

[0046] (1b) Epitaxial growth of N-type low-doped SiC epitaxial layer, such as image 3 (b) shown.

[0047] A nitrogen-doped N-type doped epitaxial layer is epitaxially grown on the cleaned SiC sample ...

Embodiment 2

[0061] Embodiment 2, preparation β radiation source is Ni 63 , PIN-type β-irradiated cells with sandwich parallel epitaxial GaN with a thickness of β-radiation source layer of 5 μm.

[0062] Step 1: Make the lower PIN knot.

[0063] 1a) Clean the 4H-SiC sample to remove surface contaminants such as image 3 (a).

[0064] This step is the same as step (1a) of Example 1.

[0065] 1b) Epitaxial growth of N-type low-doped SiC epitaxial layer, such as image 3 (b).

[0066] A nitrogen-doped N-type doped epitaxial layer is epitaxially grown on the cleaned SiC sample by chemical vapor deposition CVD. The process conditions are: epitaxy temperature is 1570°C, pressure is 100mbar, reaction gas is silane and propane, carrier gas is pure hydrogen, magazine source is liquid nitrogen, and the concentration of nitrogen doping is 1.5x10 15 cm -3 , growth of an N-type low-doped SiC epitaxial layer with a thickness of 22 μm.

[0067] 1c) Epitaxial growth of P-type highly doped GaN epit...

Embodiment 3

[0077] Embodiment 3, preparation β radiation source is Pm 147 , PIN-type β-irradiated cells with sandwich parallel epitaxial GaN with a thickness of β-radiation source layer of 3.5 μm.

[0078] Step A: Make the upper PIN knot.

[0079] (A1) Clean the 4H-SiC sample to remove surface contaminants, such as image 3 (a).

[0080] This step is the same as step (1a) of Example 1.

[0081] (A2) A nitrogen-doped N-type low-doped SiC epitaxial layer is epitaxially grown on the cleaned SiC sample by chemical vapor deposition CVD. The process conditions are as follows: the epitaxy temperature is 1570°C, the pressure is 100mbar, the reaction gas is silane and propane, the carrier gas is pure hydrogen, and the magazine source is liquid nitrogen. A nitrogen doping concentration of 2x10 15 cm -3 , a N-type low-doped SiC epitaxial layer with a thickness of 30 μm such as image 3 (b).

[0082] (A3) Put the sample after growing the N-type low-doped SiC epitaxial layer into the chemical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com