Preparation method and application of cinnamaldehyde submicroemulsion for injection

A technology of cinnamon aldehyde and submicron emulsion, which is applied in anti-inflammatory agents, emulsion delivery, active ingredients of aldehydes, etc. It can solve the problems of reduced anti-tumor activity, adverse reactions in the gastrointestinal tract, frequent administration, etc., and achieve stable preparations Good performance, low direct cost, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

[0041] Example 1: Preparation of cinnamon aldehyde submicroemulsion injection

[0042] [Prescription] 1.0g cinnamaldehyde, 20.7g refined soybean oil, 2.4g egg yolk lecithin, 5.4g glycerol, 0.2g sodium oleate, 0.2g vitamin E, water for injection to 200ml

[0043] 【Preparation】

[0044] (1) Preparation of oil phase: heat 20.7 g of refined soybean oil to 55°C, add 2.4 g of egg yolk lecithin to dissolve, add 1.0 g of cinnamaldehyde, and stir to dissolve;

[0045] (2) Preparation of water phase: add sodium oleate and glycerol to dissolve in water, and heat to 55°C;

[0046] (3) Preparation of colostrum: add step (1) oil phase to step (2) water phase, temperature 55℃, high-speed shear dispersion, shear speed 20,000 rpm, time 10 minutes, form colostrum, and quickly cool down to 15 -30℃;

[0047] (4) High pressure homogenization: Step (3) colostrum is homogenized 3 times by high pressure, the pressure is 1300 bar, and the temperature is controlled at 20°C;

[0048] (5) Filling: Filling and seali...

Embodiment 2

[0052] Example 2: Pilot-scale preparation of cinnamon aldehyde submicroemulsion injection

[0053] [Prescription] Cinnamaldehyde 10.0g, refined soybean oil 200.0g, egg yolk lecithin 24.0g, glycerol 50.0g, sodium oleate 2.0g, vitamin E 2.0g, water for injection to 2000mL

[0054] [Preparation method] Same as Example 1.

Embodiment 3

[0055] Example 3: Preparation of cinnamaldehyde nanoparticles

[0056] [Prescription] Cinnamaldehyde 8.0g, Tween-8064.0g, Absolute Ethanol 6.0g, 1,2-Propanediol 4.0g, Vitamin E4.0g, Water for Injection 120mL

[0057] [Preparation method] According to the preparation method of Ouyang Wuqing et al. (an oil-in-water cinnamaldehyde nanoemulsion drug).

[0058] (2) The physical and chemical properties of cinnamon aldehyde submicroemulsion injection and the comparative study on its superiority characteristics

[0059] 1. Physical and chemical indexes of submicroemulsion injection

[0060] (1) The stability of the submicroemulsion: After the influencing factor test, it is found that the prepared submicroemulsion injection (instruction attached figure 1 : Finished product photo) Under high temperature (60±2℃), high humidity (RH75±5%, 25±2℃), strong light irradiation (4500±500LX), it is stable for 10 days.

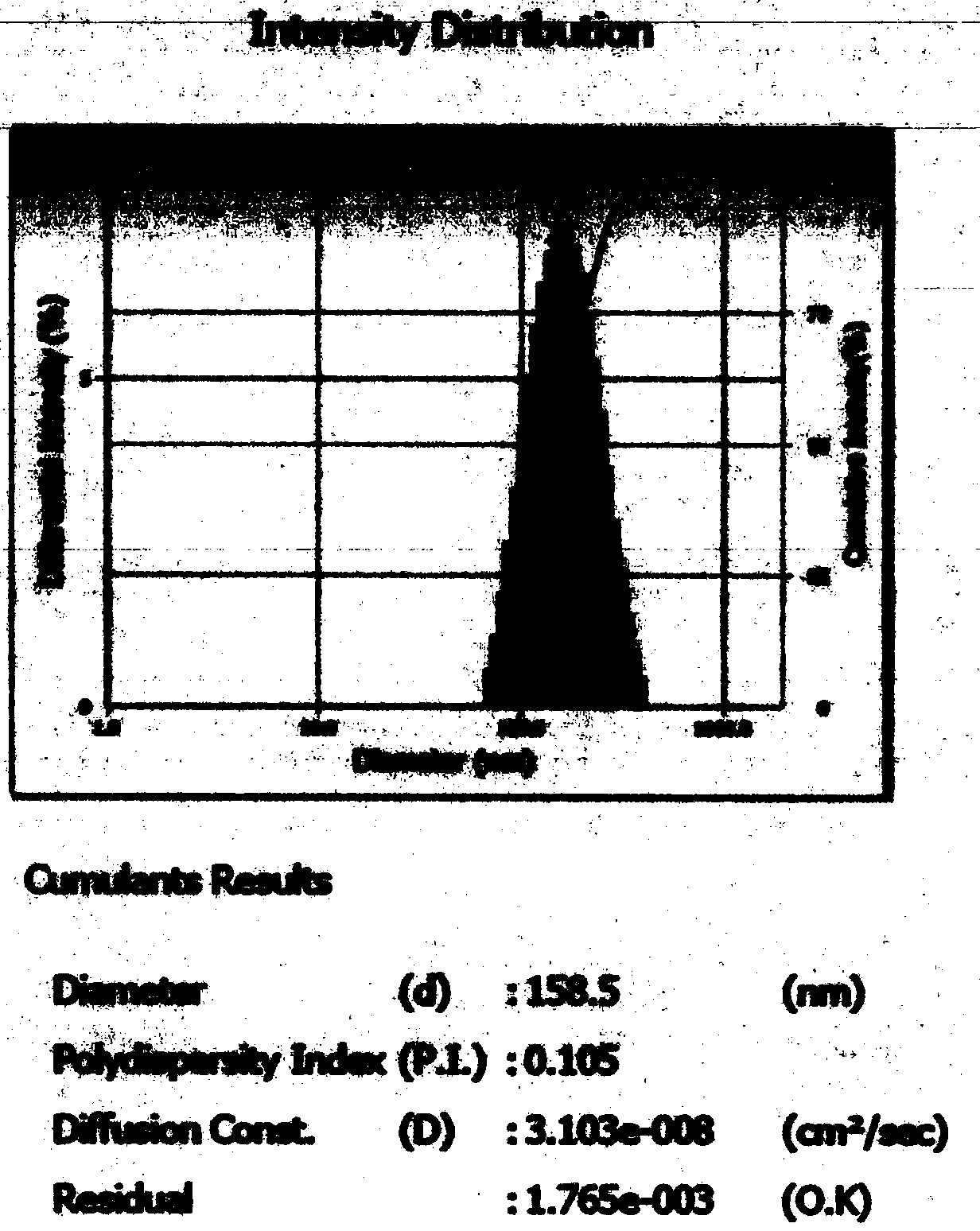

[0061] (2) Particle size of submicron emulsion: Take this product, dilute it with distill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com