Patella tissue engineering scaffold and its manufacturing material and preparation method

A tissue engineering scaffold, patella technology, applied in the field of biomedical tissue engineering, can solve the problems of synovitis, metal deposition disease, human harm, low contact stress, etc., achieve good biocompatibility and mechanical properties, reduce wear and tear Chip generation and wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

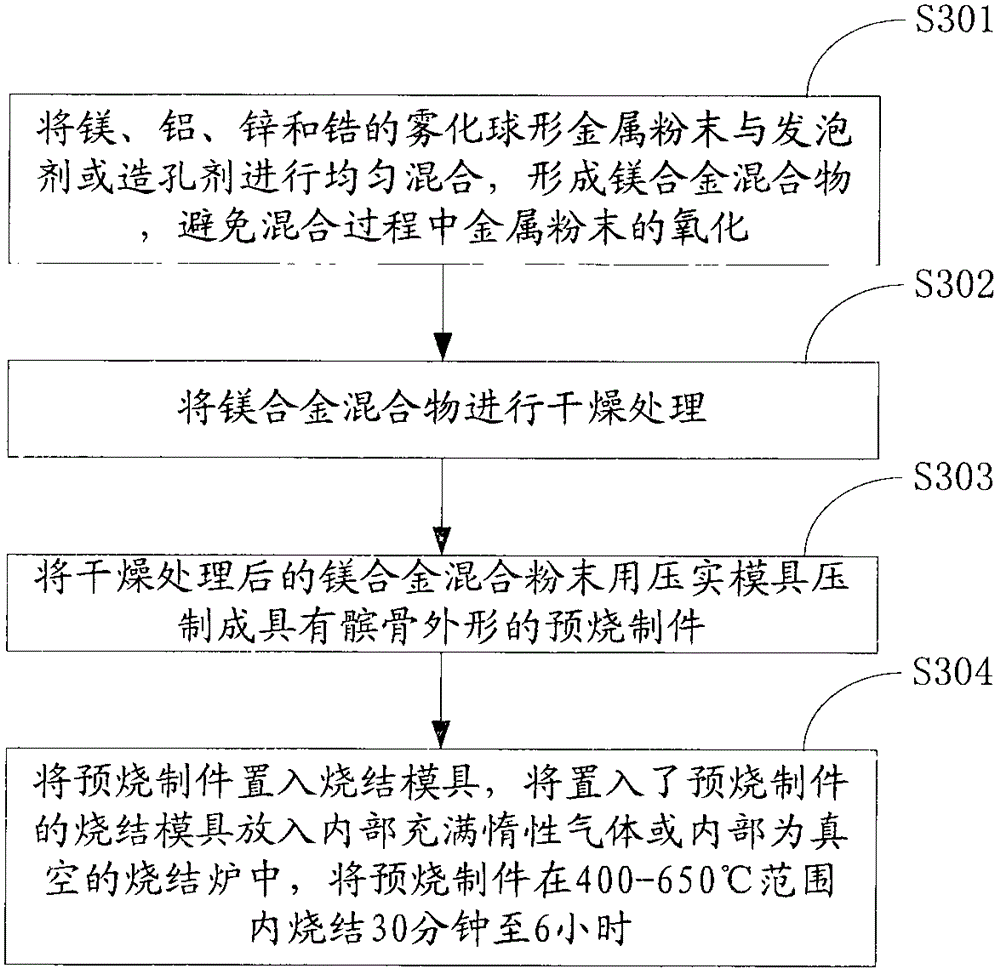

[0053] The materials for manufacturing the patella tissue engineering support, the patella tissue engineering support and the preparation method thereof will be further described below through specific embodiments and accompanying drawings.

[0054] A kind of material that is used to manufacture patella tissue engineering bracket, this material is formed by magnesium (Mg), aluminum (Al), zinc (Zn) and zirconium (Zr), wherein, the mass ratio of magnesium, aluminum, zinc and zirconium is: 85~95: 0~6: 0~4: 0~4.

[0055] A patella tissue engineering scaffold formed of magnesium (Mg), aluminum (Al), zinc (Zn) and zirconium (Zr), wherein the mass ratio of magnesium, aluminum, zinc and zirconium is: 85-95:0-6 : 0~4: 0~4.

[0056] The shape of the above-mentioned patella tissue engineering scaffold is consistent with that of the human patella. The patellar tissue engineering scaffold is formed by interweaving trabeculae, and a plurality of interconnected holes are formed between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com