Metal oxide nano fiber for VOCs catalytic oxidation and preparation method thereof

A nanofiber, catalytic oxidation technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of low concentration and rate of pollutants, and achieve dispersion promotion, large specific surface area, and enhanced adsorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1, the Ce(NO of 0.0085mol 3 ) 3 ·6H 2 O and 0.0015mol of Cu(NO 3 ) 2 ·3H 2 O was added to 6ml of absolute ethanol and 10ml of deionized water, magnetically stirred and mixed evenly for 1 hour, then polyvinylpyrrolidone (PVP) with a molecular weight of 1,300,000 was added to the above solution and stirred for 12 hours to obtain a uniform translucent sol solution.

[0042] Step 2: Use a 21G dispensing needle to electrospin primary nanofibers under the conditions of an injection pump injection speed of 0.5ml / h, a voltage of 15kV, a receiving distance of 15cm, and a drum rotation speed of 100r / min.

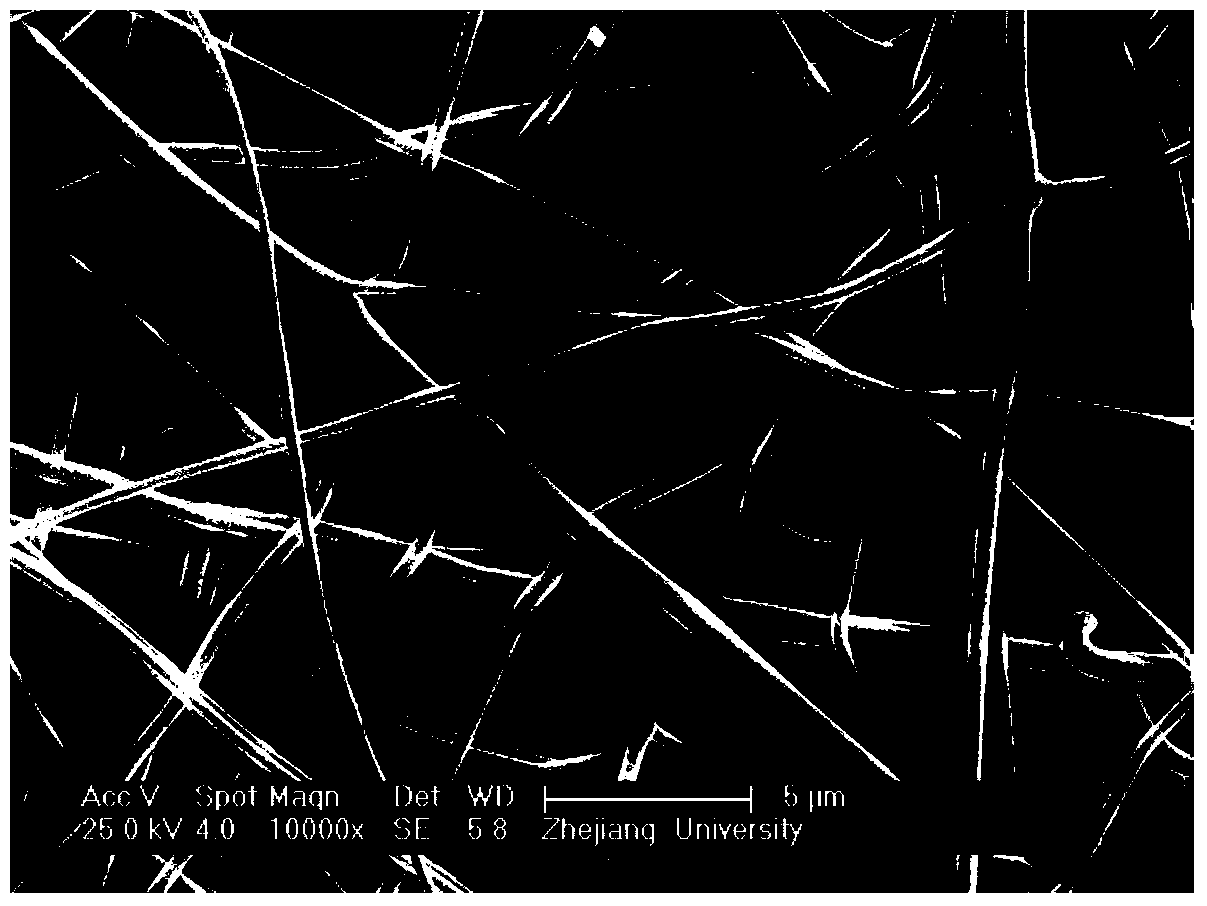

[0043] Step 3: Heating to 500°C in a muffle furnace at a heating rate of 5°C / min and maintaining it for 4 hours, finally obtaining cerium oxide / copper oxide nanofibers with a diameter distribution of 200-800nm, an average diameter of 345nm, and a specific surface area of 46.3 m 2 / g.

[0044] Weigh 35 mg of cerium oxide / copper oxide nanofibers prepared in this exa...

Embodiment 2

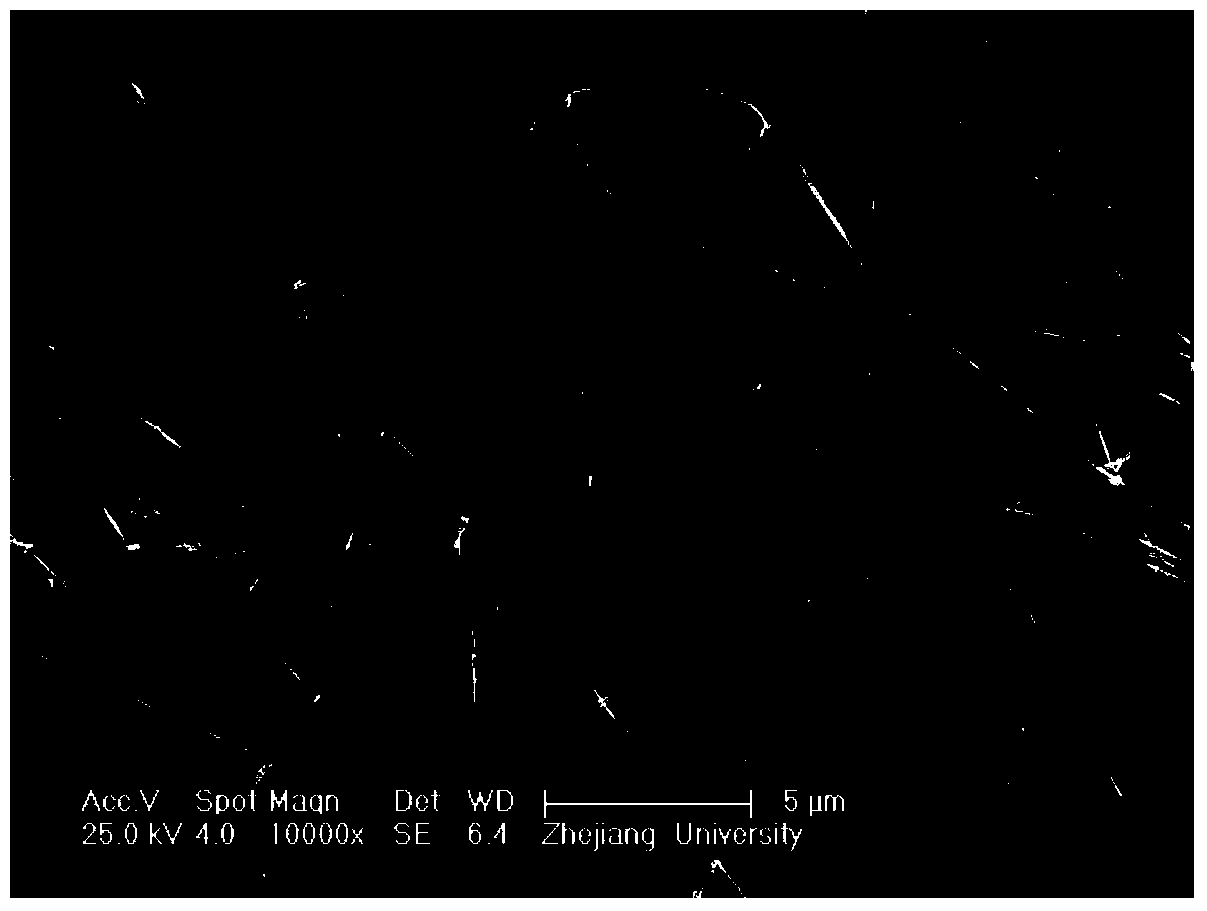

[0046] According to the same method in Example 1, 0.0070mol of Ce(NO 3 )3 ·6H 2 O and 0.0030mol of Cu(NO 3 ) 2 ·3H 2 O was added to absolute ethanol and deionized water to prepare cerium oxide / copper oxide nanofibers with a Cu / (Cu+Ce) molar ratio of 0.30, with an average diameter of 340 nm and a specific surface area of 52.5 m 2 / g.

[0047] Take 35 mg of cerium oxide / copper oxide nanofibers prepared in this example as a catalyst, place them in a fixed bed reactor, and use them for the oxidation removal reaction of industrial tail gas VOCs. The composition of the simulated tail gas gas is: 500 ppm acetone, 5 vol% oxygen, nitrogen As the balance gas, the space velocity is 79,000ml / g·h, and the reaction temperature is 195°C when the conversion rate of VOCs reaches 50%.

Embodiment 3

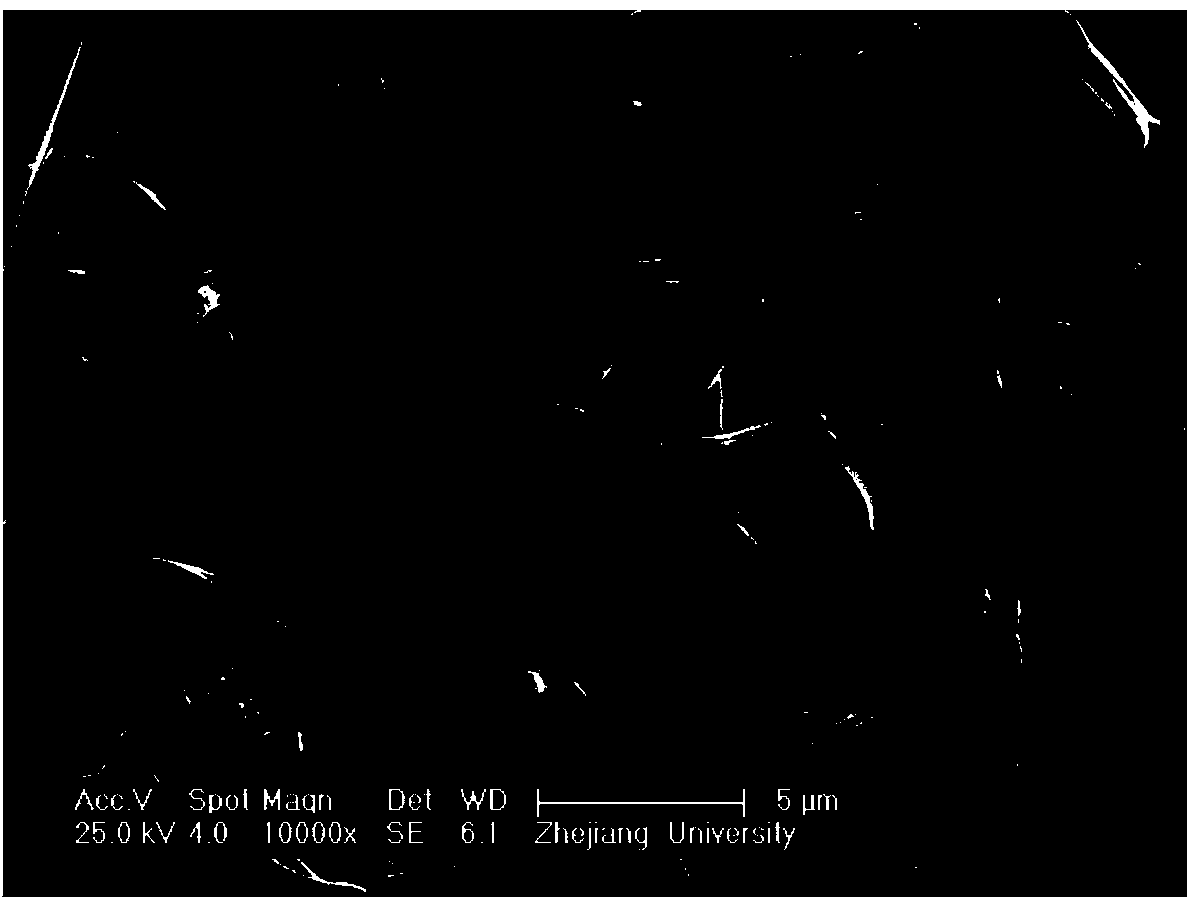

[0049] According to the same method in Example 1, 0.0050mol of Ce(NO 3 ) 3 ·6H 2 O and 0.0050mol of Cu(NO 3 ) 2 ·3H 2 O was added to absolute ethanol and deionized water to prepare cerium oxide / copper oxide nanofibers with a Cu / (Cu+Ce) molar ratio of 0.50, with an average diameter of 295 nm and a specific surface area of 74.5 m 2 / g.

[0050] Take 35 mg of cerium oxide / copper oxide nanofibers prepared in this example as a catalyst, place them in a fixed bed reactor, and use them for the oxidation removal reaction of industrial tail gas VOCs. The composition of the simulated tail gas gas is: 500 ppm acetone, 5 vol% oxygen, nitrogen As the balance gas, the space velocity is 79,000ml / g·h, and the reaction temperature is 190°C when the conversion rate of VOCs reaches 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com