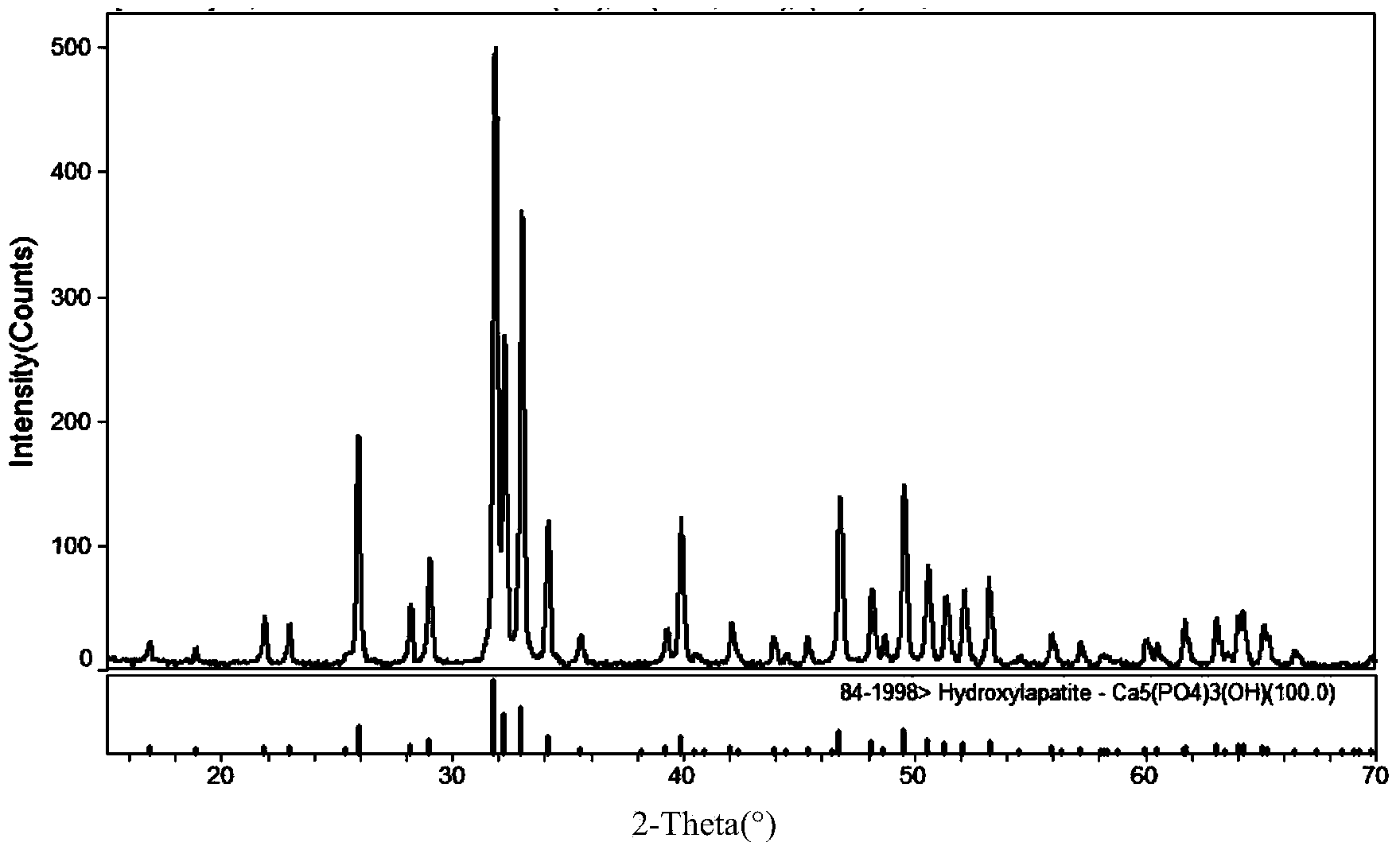

Preparation method of hydroxyapatite material doped with fluorine and potassium

A technology of potassium hydroxyapatite and calcium phosphate powder, which is applied in chemical instruments and methods, dental preparations, phosphorus compounds, etc., can solve the problems of large output and unreported research, achieve less impurities, simple preparation process, and enhanced The effect of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the present invention comprises the following steps:

[0040] 1) Press Ca(NO 3 ) 2 4H 2 O and H 3 PO 4 The molar ratio is 3:2 to weigh raw materials, Ca(NO 3 ) 2 4H 2 O was mixed with distilled water at a mass ratio of 1:10, and then H 3 PO 4 Mix with distilled water at a mass ratio of 1:45, and then add H 3 PO 4 Aqueous solution was added to Ca(NO 3 ) 2 The solution is mixed evenly to obtain a mixed solution, and the pH of the mixed solution is adjusted with NaOH solution so that the pH value of the mixed solution system is maintained at 8-10, and then the mixed solution is centrifuged, continuously washed, and suction filtered.

[0041] 2) Put the precipitate obtained in step 1) into a muffle furnace, heat and keep it at 200°C for 1 hour, take it out, grind it, then put it into a corundum crucible and raise the temperature to 1300°C at 10°C / min, and keep it warm for 2 hours , Take it out immediately, and make a white powder after...

Embodiment 2

[0046] The preparation method of the present invention comprises the following steps:

[0047] 1) Press Ca(NO 3 ) 2 4H 2 O and H 3 PO 4 The molar ratio is 3:2 to weigh raw materials, Ca(NO 3 ) 2 4H 2 O was mixed with distilled water at a mass ratio of 1:12, and then H 3 PO 4 Mix with distilled water at a mass ratio of 1:90, and then add H 3 PO 4 Aqueous solution was added to Ca(NO 3 ) 2 The solution is mixed evenly to obtain a mixed solution, and the pH of the mixed solution is adjusted with NaOH solution so that the pH value of the mixed solution system is maintained at 11-12, and then the mixed solution is centrifuged, continuously washed, and suction filtered.

[0048] 2) Put the product obtained in step 1) into a muffle furnace, heat and keep it at 150°C for 1.5 hours, take it out, grind it, then put it into a corundum crucible and raise the temperature to 1400°C at 10°C / min, and keep it warm for 0.5 hours, Take it out immediately, and after cooling, the white...

Embodiment 3

[0052] The preparation method of the present invention comprises the following steps:

[0053] 1) Press Ca(NO 3 ) 2 4H 2 O and H 3 PO 4 The molar ratio is 3:2 to weigh raw materials, Ca(NO 3 ) 2 4H 2 O was mixed with distilled water at a mass ratio of 1:14, and then H 3 PO 4 Mix with distilled water at a mass ratio of 1:80, and then add H 3 PO 4 Aqueous solution was added to Ca(NO 3 ) 2 The solution is mixed uniformly to obtain a mixed solution, and the pH of the mixed solution is adjusted with NaOH solution so that the pH value of the mixed solution system is maintained at 13-14, and then the mixed solution is centrifuged, continuously washed, and suction filtered.

[0054] 2) Put the precipitate obtained in step 1) into a muffle furnace, heat it at 100°C for 2 hours, take it out, grind it, then put it into a corundum crucible and raise the temperature to 1350°C at 10°C / min, and keep it warm for 1 hour , Take it out immediately, and make a white powder after cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com