Graphene-based dielectric elastomer composite material and preparation method thereof

A technology for dielectric elastomers and composite materials, applied in the field of electroactive polymers, can solve the problems of reduced electrical breakdown strength, reduced modulus, and increased dielectric loss of materials, so as to improve the electro-deformation performance and improve the dielectric properties. Constant, the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) 50mg of graphite oxide synthesized by the Hummers method, ultrasonically dispersed in 500mL of deionized water, ultrasonically dispersed at 1000W for 1h, the graphite oxide was exfoliated into flaky graphene oxide (average thickness is about 0.8-1nm), and a stable suspension was obtained Graphene oxide aqueous solution; ultrasonically disperse 100mg nanocarbon spheres (average particle size is about 100nm) in 500mL deionized water, 1000W ultrasonic 2h to obtain a stable black suspension;

[0043] (2) Mix the graphene oxide aqueous solution and the nanocarbon sphere suspension that have been ultrasonically dispersed in step (1) at room temperature, and react with mechanical stirring for 6 hours. Core-shell hybrid particles coated with carbon nanospheres.

[0044] (3) the 8mg core-shell hybrid particle that step (2) is prepared is ultrasonically dispersed in deionized water, and then mixed with 10g of carboxylated nitrile rubber emulsion (the brand produced by Zeon co...

Embodiment 2

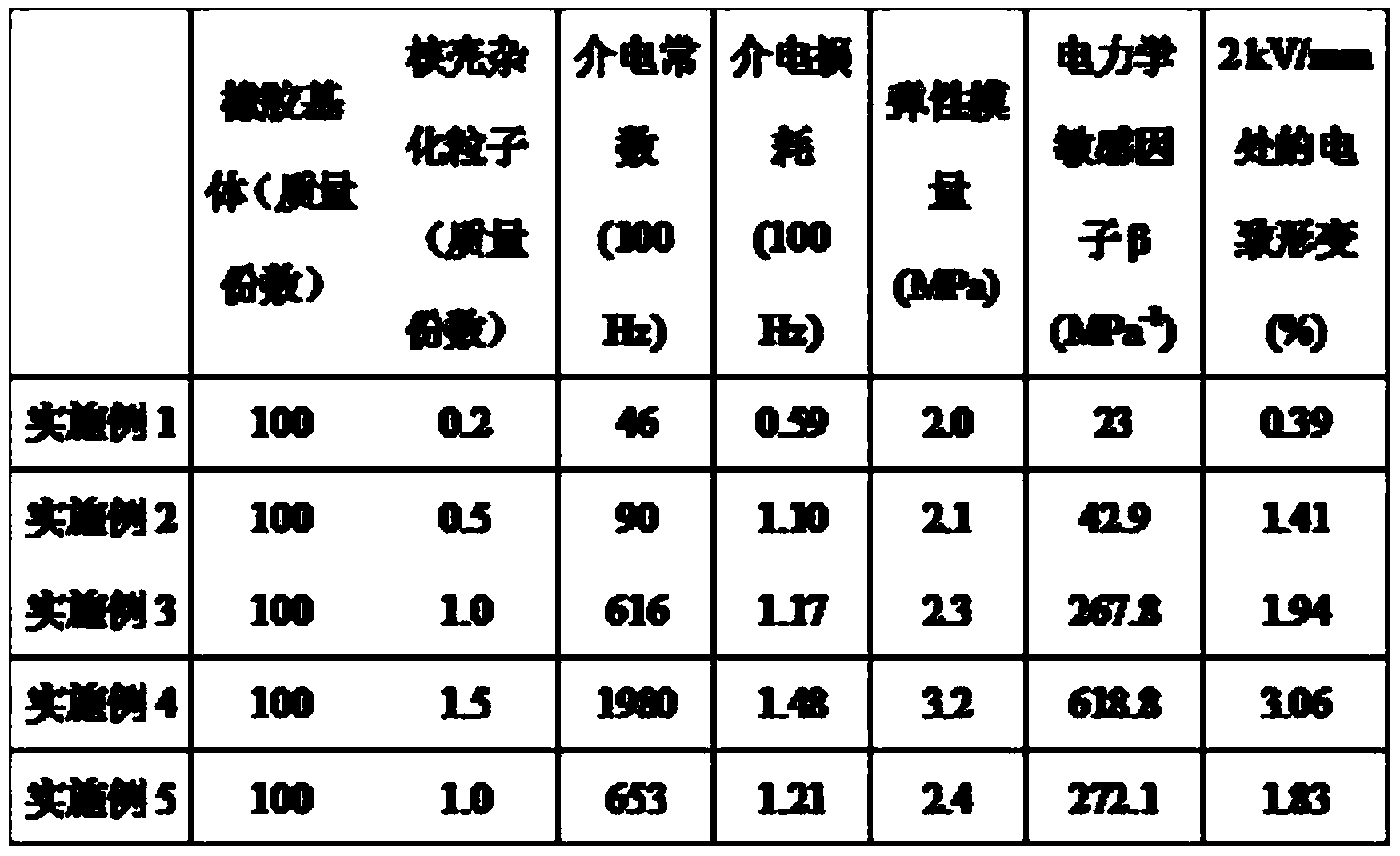

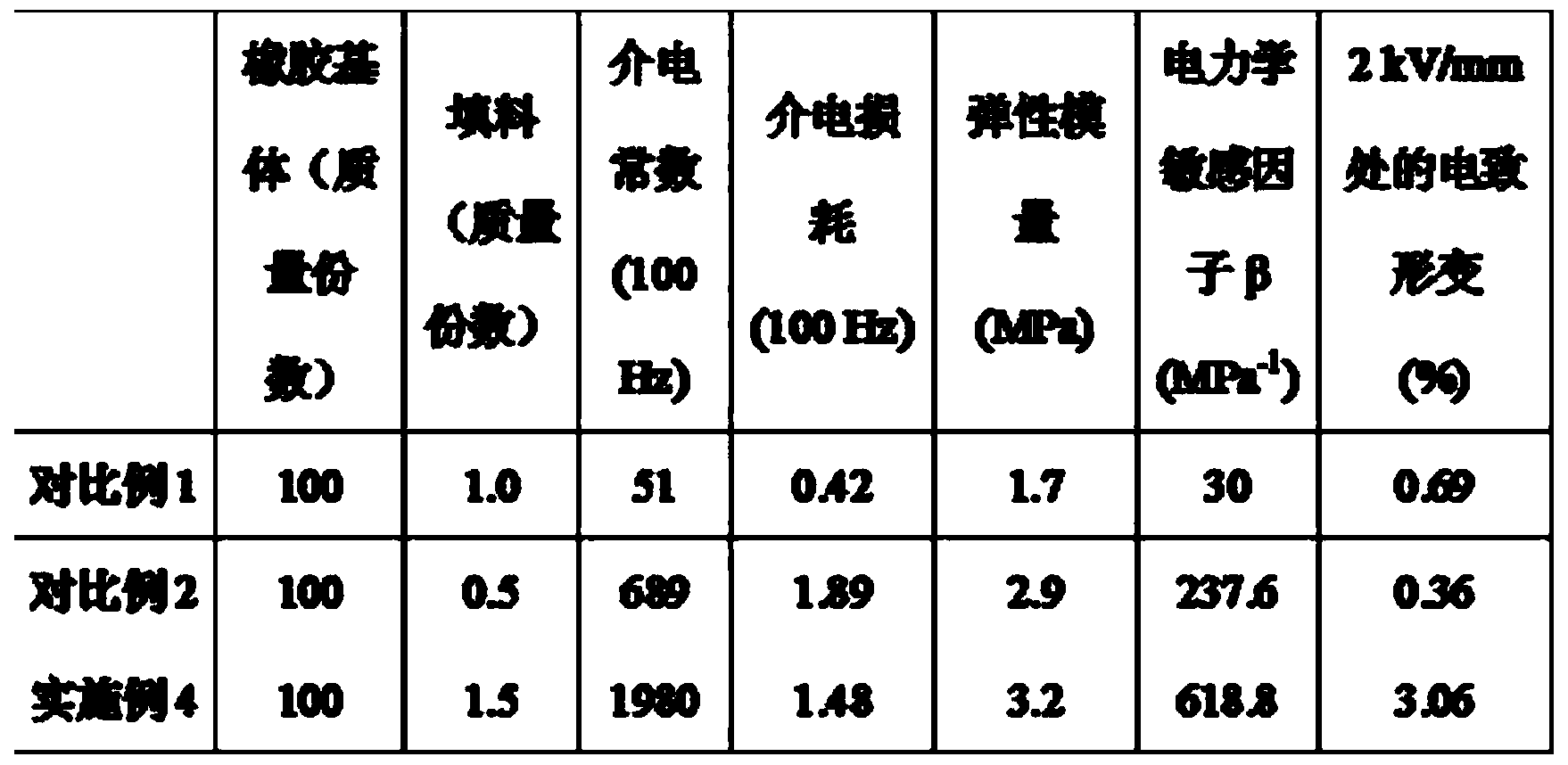

[0049] The preparation method is the same as in Example 1, except that the amount of core-shell hybrid particles used in step (3) is 20 mg, and the crosslinking system is 0.02 g of di-tert-butylperoxycumene and 0.02 g of triallyl cyanuric acid ester. The test results are shown in Table 1.

Embodiment 3

[0051] The preparation method is the same as that in Example 1, except that in step (2) the mechanical stirring is for 3 h, and the amount of core-shell hybrid particles used in step (3) is 40 mg. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com