Method for boiler flue gas denitration

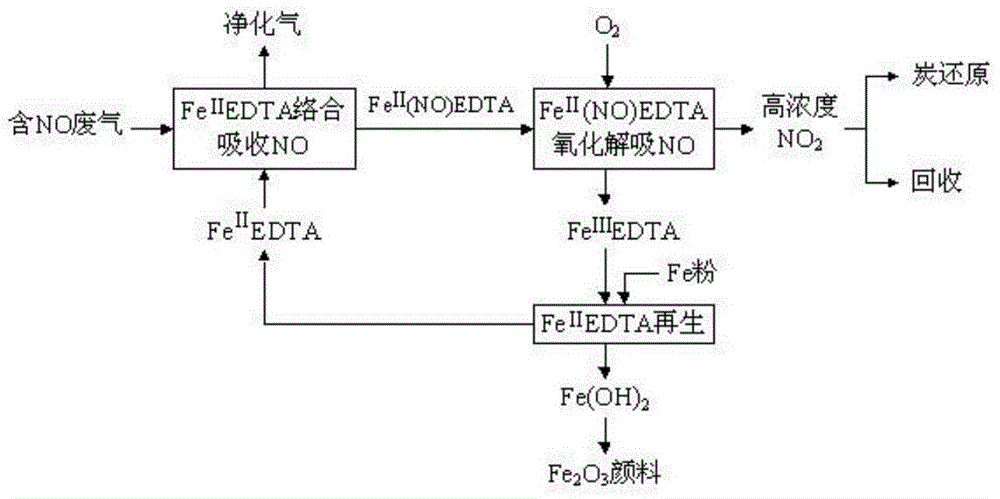

A technology for boiler flue gas and denitration, which is applied in the field of flue gas purification, can solve the problems of high cost of electrolysis and unfavorable industrial applications, and achieve the effects of high absorption efficiency, convenient maintenance and simple regeneration process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

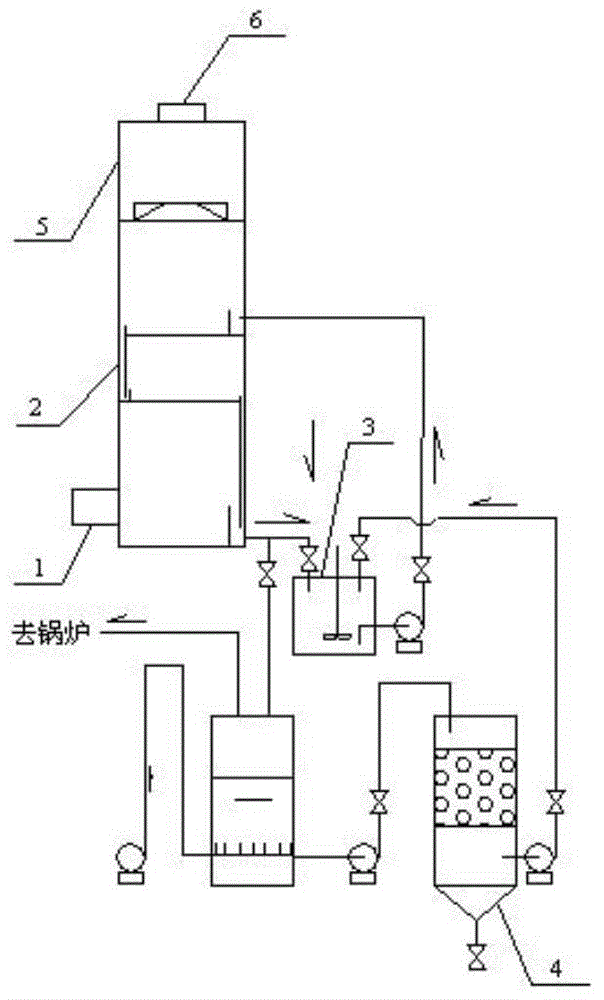

Embodiment 1

[0043] Fe Ⅱ EDTA complexation absorbs NO in simulated flue gas: a sieve plate absorption tower with a diameter of 100mm and a height of 1200mm is used as the absorber, with 2 layers of sieve plates built in, and the opening rate is 17%. Simulated NO exhaust gas flow rate 20m 3 / h, including NO500×10 -6 , the absorption solution Fe Ⅱ EDTA concentration is 25mmol·L -1 , the circulation volume is 80L / h, the reaction temperature is 333K, the initial pH of the complex solution is 5.5, and the NO removal rate is 95%. The desorption device is a bubbling bed with a height of 200mm and a height of 400mm, and the aeration air volume is 2m 3 / h, at 303K, react for 8 minutes, and the desorption is complete; the regeneration device is an iron filings packed bed reactor with a diameter of 200mm and a height of 400mm, containing Fe Ⅲ The solution of EDTA is sprayed on the iron filler, the spray density is 0.6m 3 / (m 2 h), residence time 3 seconds, Fe Ⅱ EDTA is completely regenerated ...

Embodiment 2

[0045] Fe Ⅱ EDTA complexation absorbs NO in simulated flue gas: a sieve plate absorption tower with a diameter of 100mm and a height of 1200mm is used as the absorber, with 2 layers of sieve plates built in, and the opening rate is 17%. Simulated NO exhaust gas flow rate 20m 3 / h, including NO600×10 -6 , the absorption solution Fe Ⅱ EDTA concentration is 25mmol·L -1 , the circulation volume is 80L / h, the reaction temperature is 333K, the initial pH of the complex solution is 5.5, and the NO removal rate is 92%. The desorption device is a bubbling bed with a height of 200mm and a height of 400mm, and the aeration air volume is 2m 3 / h, at 313K, react for 10 minutes, and the desorption is complete; the regeneration device is an iron filings packed bed reactor with a diameter of 200mm and a height of 400mm, containing Fe Ⅲ The solution of EDTA is sprayed on the iron filler, the spray density is 0.6m 3 / (m 2 h), residence time 3 seconds, Fe Ⅱ EDTA is completely regenerated...

Embodiment 3

[0047] Fe Ⅱ EDTA complexation absorbs NO in simulated flue gas: a sieve plate absorption tower with a diameter of 100mm and a height of 1200mm is used as the absorber, with 2 layers of sieve plates built in, and the opening rate is 17%. Simulated NO exhaust gas flow rate 20m 3 / h, including NO500×10 -6 , the absorption solution Fe Ⅱ EDTA concentration is 20mmol·L -1 , the circulation volume is 60L / h, the reaction temperature is 343K, the initial pH of the complexing solution is 6.0, and the NO removal rate reaches 92%. The desorption device is a bubbling bed with a height of 200mm and a height of 400mm, and the aeration air volume is 2m 3 / h, at 323K, react for 8 minutes, and the desorption is complete; the regeneration device is an iron filings packed bed reactor with a diameter of 200mm and a height of 400mm, containing Fe Ⅲ The solution of EDTA is sprayed on the iron filler, the spray density is 0.6m 3 / (m 2 h), residence time 3 seconds, Fe Ⅱ EDTA is completely rege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com