Preparation method for self-seed-growing nest-like tungsten oxide hydrate nanostructured electrochromic film

A seed crystal growth, nanostructure technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc. and other problems, to achieve the effect of improving the discoloration speed and coloring efficiency, which is beneficial to electron transmission and improving the coloring efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

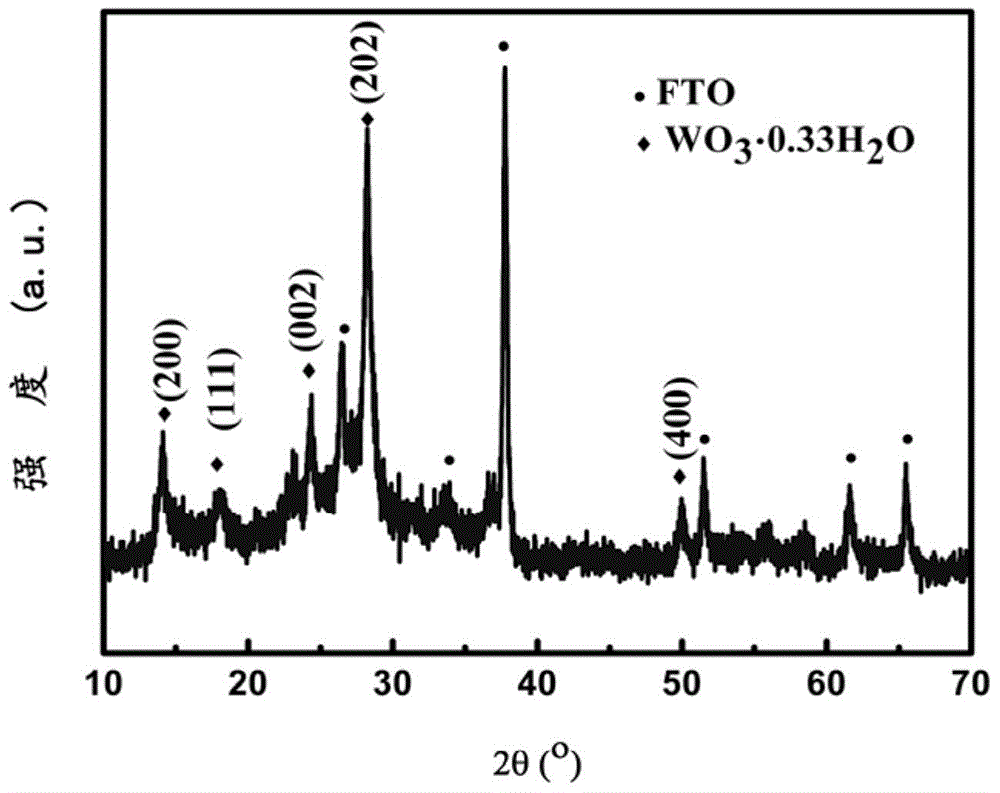

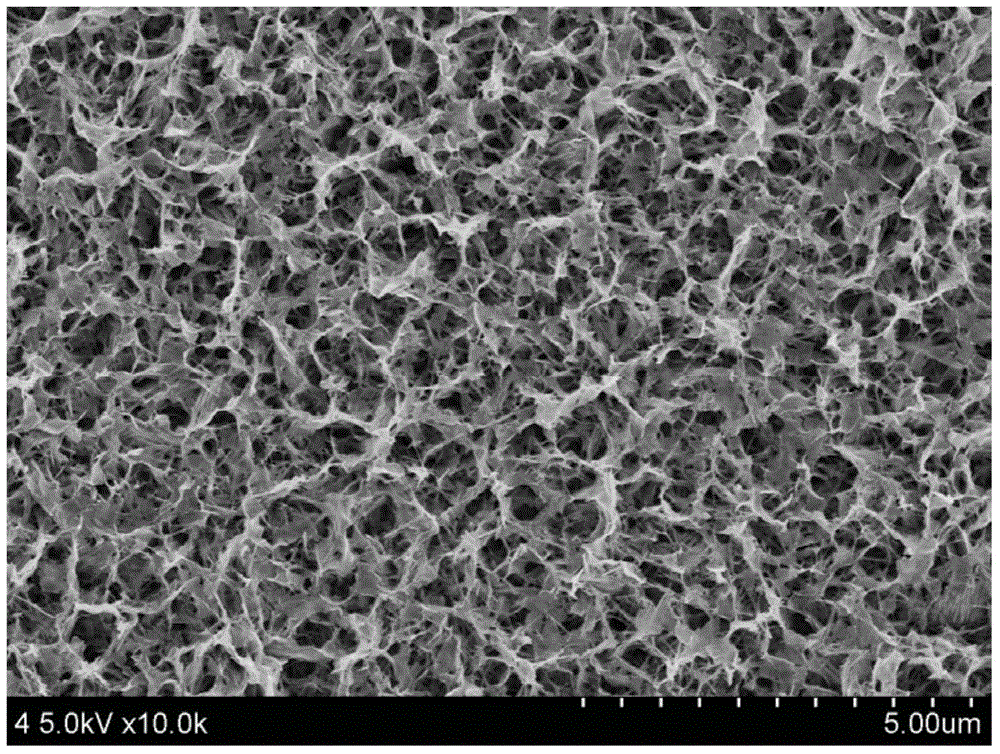

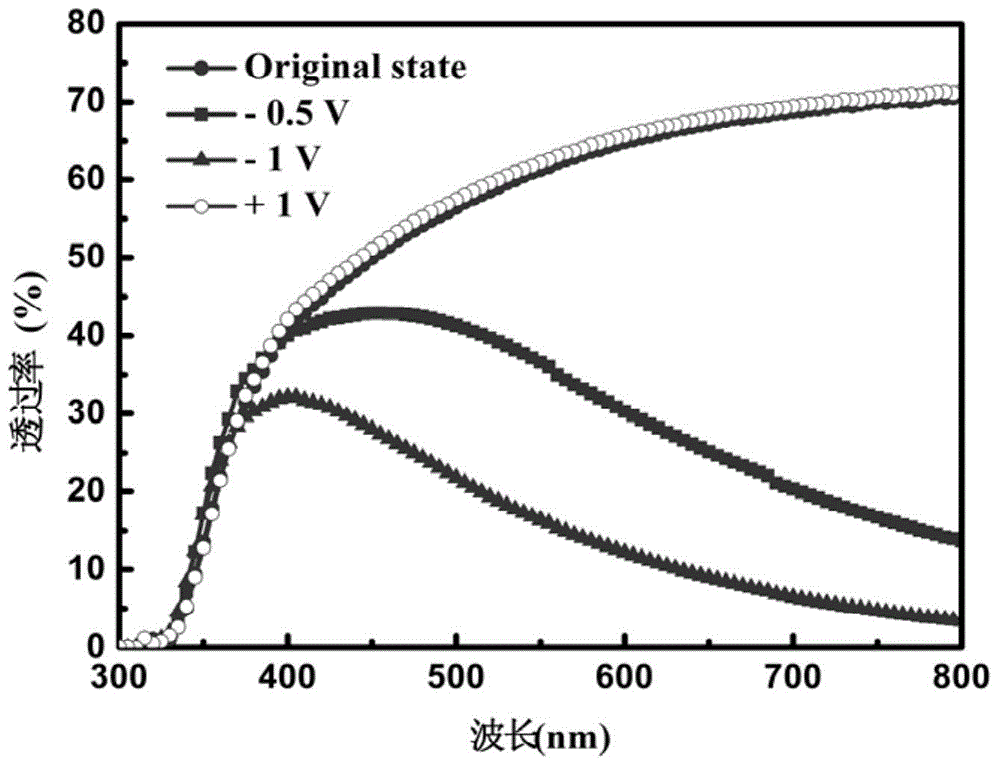

[0035] Soak the FTO conductive glass in detergent, deionized water, acetone and ethanol for 15 minutes and then dry it for later use. Weigh 5g of tungstic acid and dissolve it in 60mL of hydrogen peroxide, heat to 95°C, cool down after the tungstic acid is completely dissolved to obtain a transparent sol; dilute the transparent sol to 200mL with deionized water, take 10.5mL of the transparent sol, 3.5mL of hydrochloric acid (3mol / L), 10.5mL deionized water, and 31.5mL ethylene glycol were poured into the hydrothermal kettle, and the FTO conductive glass was immersed in the hydrothermal kettle, kept at 120°C for 2 hours, and finally cooled to room temperature naturally, and the FTO conductive glass was taken out. Wash with water and ethanol in sequence and dry. figure 1 It is the X-ray diffraction pattern of the prepared film, and it can be seen from the standard X-ray diffraction pattern that the film is an orthorhombic phase of WO 3 0.33H 2 O, corresponds to the standard c...

Embodiment 2

[0038] Soak the FTO conductive glass in detergent, deionized water, acetone and ethanol for 15 minutes and then dry it for later use. Weigh 5g of tungstic acid and dissolve it in 100mL of hydrogen peroxide, heat to 95°C, cool down after the tungstic acid is completely dissolved to obtain a transparent sol; dilute the transparent sol to 200mL with deionized water, take 10.5mL of the transparent sol, 3.5mL of hydrochloric acid (3mol / L), 10.5mL deionized water, and 31.5mL ethylene glycol were poured into the hydrothermal kettle, and the FTO conductive glass coated with the seed layer was immersed in the hydrothermal kettle, kept at 120°C for 1 hour, and finally cooled naturally to At room temperature, take out the FTO conductive glass, wash it with water and ethanol in sequence, and then dry it. Image 6It is the X-ray diffraction pattern of the prepared film, and it can be seen from the standard X-ray diffraction pattern that the film is an orthorhombic phase of WO 3 0.33H 2 O...

Embodiment 3

[0041] Soak the FTO conductive glass in detergent, deionized water, acetone and ethanol for 15 minutes and then dry it for later use. Weigh 5g of tungstic acid and dissolve it in 80mL of hydrogen peroxide, heat to 95°C, cool down after the tungstic acid is completely dissolved to obtain a transparent sol; dilute the transparent sol to 200mL with deionized water, take 10.5mL of the transparent sol, 3.5mL of hydrochloric acid (3mol / L), 14mL deionized water, and 28mL ethylene glycol were poured into the hydrothermal kettle, and the FTO conductive glass was immersed in the hydrothermal kettle, kept at 120°C for 2 hours, and finally cooled to room temperature naturally, the FTO conductive glass was taken out, and water and Wash with ethanol and then dry. Figure 11 It is the X-ray diffraction pattern of the prepared film, and it can be seen from the standard X-ray diffraction pattern that the film is an orthorhombic phase of WO 3 0.33H 2 O, corresponds to the standard card JCPDS5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com