Low-smoke, halogen-free and flame-retardant cable material used for coal mine, and preparation method thereof

A flame-retardant cable material and coal mine technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of uneven particle size of samples, increase processing costs, and dyeing of materials, so as to reduce the amount of smoke generated, Improve the effect of flame retardancy and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

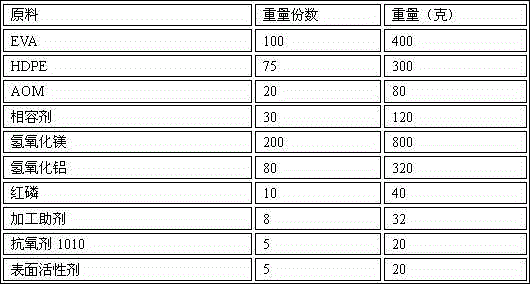

[0048] A low-smoke halogen-free flame-retardant cable material used in coal mines, the formula is as follows:

[0049]

[0050] Weigh 400 grams of EVA, 300 grams of HDPE and other ingredients according to the formula in the above table, and make a 1mm test piece according to the steps of drying, surface treatment, banburying, discharging, opening, discharging, and tableting.

Embodiment 2

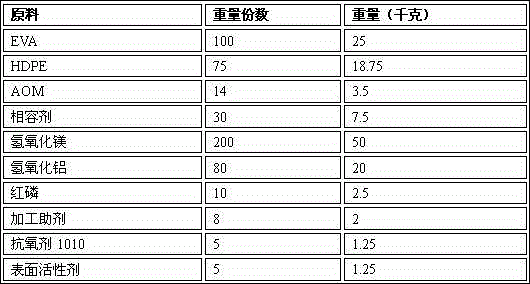

[0052] A low-smoke halogen-free flame-retardant cable material used in coal mines, the formula is as follows:

[0053]

[0054] Weigh 400 grams of EVA, 300 grams of HDPE and other ingredients according to the formula in the above table, and make a 1mm test piece according to the steps of drying, surface treatment, banburying, discharging, opening, discharging, and tableting.

Embodiment 3

[0056] A low-smoke halogen-free flame-retardant cable material used in coal mines, the formula is as follows:

[0057]

[0058] Weigh 25kg of EVA, 18.75kg of HDPE and other additives of appropriate weight according to the formula in the above table, and make a 1mm test piece according to the steps of drying, surface treatment, banburying, discharging, kneading, discharging, and tableting.

PUM

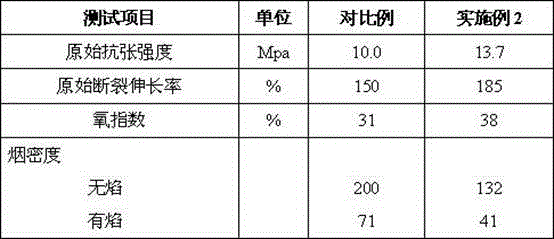

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com