Photoresponsive nanostructure film with high visible light transmittance and application thereof

A nano-structure, high-transmittance technology, applied in nanotechnology, methods of supporting/immobilizing microorganisms, tissue cell/virus culture devices, etc., can solve problems such as complex operation process, affecting cell activity, and long operation time. Achieve high efficiency, less cell damage, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Uniformly disperse nano-titanium oxide powder with a size of 10nm in water to form a nanoparticle dispersion with a mass fraction of 10%; mix the nanoparticle dispersion with ethanol and organic solvent tetrahydrofuran at a ratio of 0.02:6:1 to form a precursor body solution; the precursor solution was 20μL / cm 2 Evenly drop the concentration on the polystyrene culture vessel, and then dry it at 40°C. After drying, a light-responsive nanostructure film with a grain size of 10nm and a thickness of 20nm can be obtained, and the visible light transmittance is 98%. . After the cells were cultured on the surface of the culture dish for 24 hours, they were irradiated with 360nm light from the bottom, and the cell detachment rate reached 90.5% after 10 minutes.

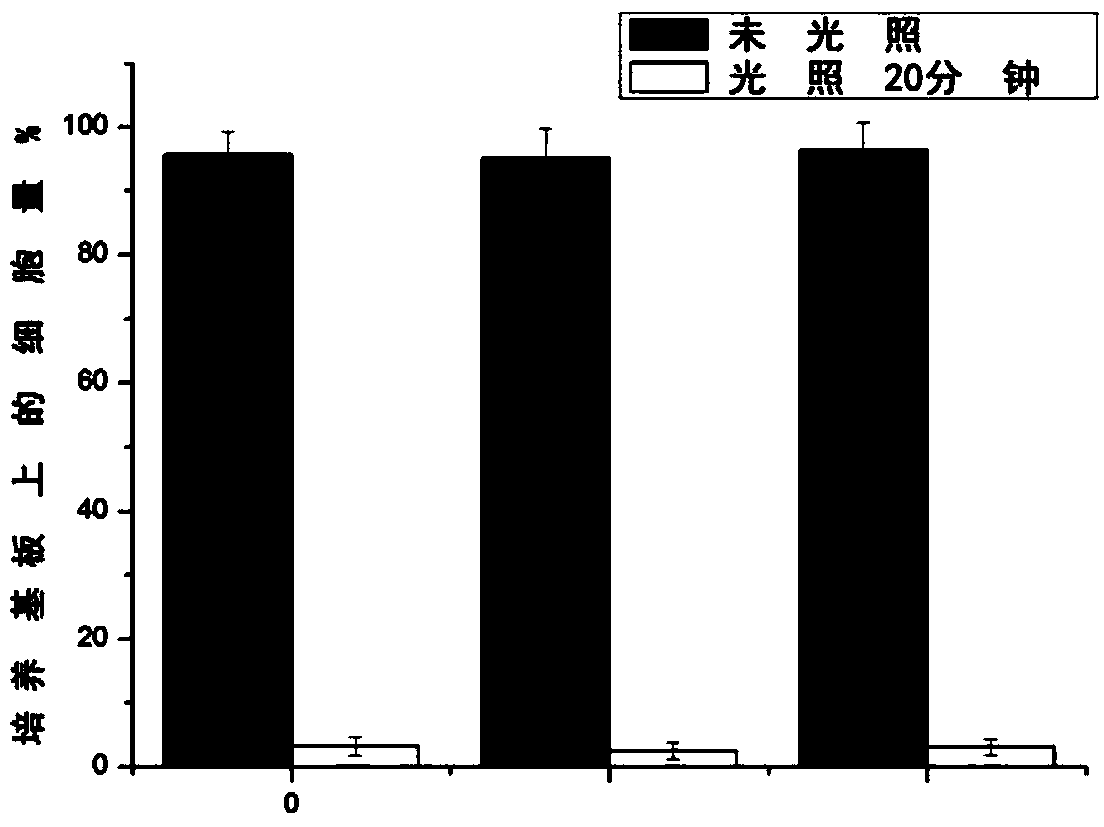

[0030] Use an inverted biological microscope to observe the cultured cells before and after UV light irradiation, the inverted micrograph is shown in figure 1 and figure 2 The present embodiment that cell counting ...

Embodiment 2

[0033] The nano-gallium nitride powder with a size of 30nm is uniformly dispersed in water to form a nanoparticle dispersion with a mass fraction of 20%; the nanoparticle dispersion is mixed with propanol and organic solvent chloroform in a ratio of 0.06: 9: 3 Make precursor solution; 2 Evenly drop the concentration on the polystyrene culture vessel, and then dry at 90°C. After drying, a light-responsive nanostructure film with a grain size of 30nm and a thickness of 100nm can be obtained, and the visible light transmittance is 89%. . . After the cells were cultured on the surface of the petri dish for 24 hours, they were irradiated with 450nm light from the bottom, and the cell detachment rate reached 92.6% after 30 minutes.

[0034]

Embodiment 3

[0036] The nano-zinc oxide powder with a size of 20nm is uniformly dispersed in water to form a nanoparticle dispersion with a mass fraction of 15%; the nanoparticle dispersion is mixed with methanol and organic solvent methylene chloride in a ratio of 0.04:8:2 into a precursor solution; the precursor solution by 40μL / cm 2 Evenly drop the concentration on the polystyrene culture vessel, and then dry at 70°C. After drying, a light-responsive nanostructure film with a grain size of 20nm and a thickness of 60nm can be obtained, and the visible light transmittance is 93%. . After culturing the cells on the surface of the culture dish for 24 hours, the cells were irradiated with 400nm light from the bottom, and the cell detachment rate reached 89.6% after 20 minutes.

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com