Taste cell sensor using surface acoustic wave resonator and preparation method thereof

A surface acoustic wave and resonator technology, applied in the field of cell sensors, can solve the problems of high price, difficult to meet rapid detection, large size of cell sensing detection system, etc., and achieve low cost, high repeatability and controllability, Good batch repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

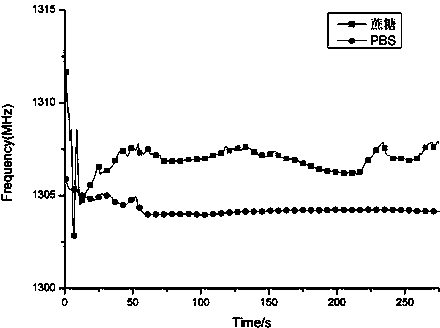

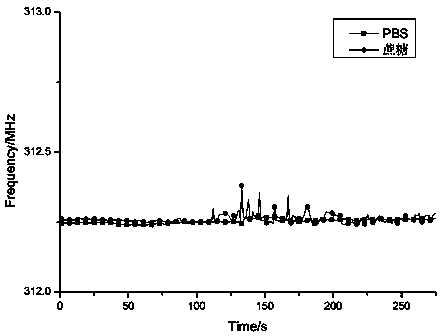

Examples

Embodiment 1

[0034] A preparation method of a taste cell sensor using a surface acoustic wave resonator, the preparation method comprising the following steps:

[0035] a) Pre-treatment: Dry the screen-printed carbon electrode at 45°C for 10 hours, then ultrasonically clean it with acetone, soak it in ultrapure water for 5 minutes, irradiate it with ultraviolet rays for 25 minutes, and dry it naturally for use; ultrasonically disperse the graphene in deionized water , to obtain a 0.3g / L suspension, evenly drop-coat the suspension on the working electrode area of the above-mentioned screen-printed carbon electrode, dry it at 50°C, and then drop-coat 100μg / ml polylysine solution on the The working electrode area of the graphene-coated screen-printed carbon electrode was left overnight at room temperature, washed 4 times with ultrapure water the next day, and dried for use;

[0036] b) NCI-H716 cell culture: NCI-H716 cell culture medium is 10% fetal bovine serum, penicillin and strept...

Embodiment 2

[0039] A preparation method of a taste cell sensor using a surface acoustic wave resonator, the preparation method comprising the following steps:

[0040] a) Pre-treatment: Dry the screen-printed carbon electrode at 50°C for 12 hours, then ultrasonically clean it with absolute ethanol, soak it in ultrapure water for 8 minutes, irradiate it with ultraviolet light for 30 minutes, and then dry it naturally; In deionized water, a 0.5g / L suspension was obtained, and the suspension was uniformly drip-coated on the working electrode area of the above-mentioned screen-printed carbon electrode, dried at 65°C, and then a 100μg / ml serine solution was drip-coated on the coating The working electrode area of the graphene-coated screen-printed carbon electrode was left overnight at room temperature, washed 6 times with ultrapure water the next day, and dried for later use;

[0041] b) NCI-H716 cell culture: NCI-H716 cell culture medium is 10% fetal bovine serum, penicillin and streptom...

Embodiment 3

[0044] A preparation method of a taste cell sensor using a surface acoustic wave resonator as claimed in claim 1, wherein the preparation method comprises the following steps:

[0045] a) Pretreatment: Dry the screen-printed carbon electrode at 60°C for 14 hours, then ultrasonically clean it with acetone, then soak it in ultrapure water for 10 minutes, irradiate it with ultraviolet rays for 35 minutes, and then dry it naturally for use; ultrasonically disperse the graphene in deionized water , to obtain a 1g / L suspension, evenly drop-coat the suspension on the working electrode area of the above-mentioned screen-printed carbon electrode, dry it at 50-80°C, and then drop-coat the 100μg / ml arginine solution on the coated The working electrode area of the graphene-coated screen-printed carbon electrode was left overnight at room temperature, washed 10 times with ultrapure water the next day, and dried for use;

[0046] b) NCI-H716 cell culture: NCI-H716 cell culture medium is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interdigital width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com