Preparation method of polyaniline-epoxy graft modified acrylic ester compound

An acrylate and graft modification technology, applied in the fields of chemical synthesis, polyaniline coating production, and coating production, can solve the problem that the anti-corrosion properties of polyaniline cannot be highlighted, it is difficult to form a dense composite coating, and the comprehensive performance of anti-corrosion coating It can achieve long-term anti-corrosion or long-term anti-corrosion and anti-static performance, adjustable flexibility, and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

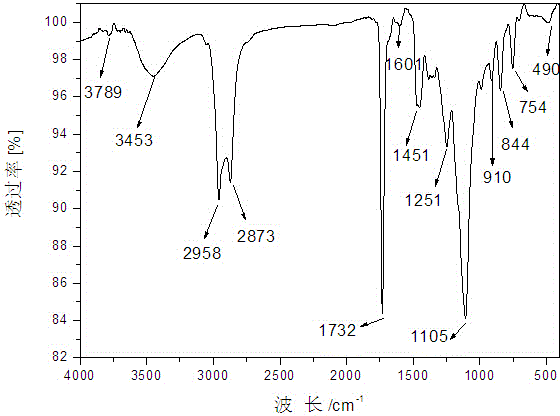

Image

Examples

Embodiment 1

[0031] Embodiment 1 step:

[0032] Dissolve 5.44g of E-51 epoxy resin in 50g of toluene, add it into a four-necked flask equipped with a stirrer, thermometer, and reflux condenser, and heat it to 95°C in a water bath to form solution 1.

[0033] Take 27.58g of methyl methacrylate, 2.72g of acrylic acid, 18.39g of butyl acrylate, 1.5g of BPO (benzoyl peroxide), 0.272g of acrylamide, dissolve in 50g of toluene, mix well and add to the constant pressure dropping funnel , forming solution II.

[0034] The solution two was added dropwise to the solution one, and after 3 hours of dropwise addition, the temperature of the mixed system was raised to 98°C. After being kept warm for 2 hours, and then lowered to 0°C, 6.528g of aniline was added, stirred for 30 minutes, and an oxidative polymerization initiator solution composed of 16.99g of BPO dissolved in 15.6g of butyl acetate was added dropwise for oxidative polymerization initiation of the dropwise addition. The temperature of the...

Embodiment 2

[0035] Embodiment 2 steps:

[0036] Dissolve 6.8g of E-44 epoxy resin in 50g of toluene, add it into a four-necked flask equipped with a stirrer, thermometer, and reflux condenser, and heat it to 94°C in a water bath to form solution 1.

[0037] Take 34.476g methyl methacrylate, 3.4g methacrylic acid, 22.984g ethyl acrylate, 1.8g dicumyl peroxide, 0.34g acrylamide, dissolve in 40g toluene, mix well and add to the constant pressure dropping funnel , forming solution two.

[0038]Add two drops of solution into solution one. After 3 hours of dropwise addition, raise the temperature of the mixed system to 98°C, keep warm for 2 hours, then cool down to 0°C, then add 4.08g of aniline, stir for 30min, dropwise add 10.6g of peroxide Dissolve dicumyl in an oxidative polymerization initiator solution composed of 12g methyl ethyl ketone, add dropwise the oxidative polymerization initiator solution for dripping. Polyacrylate compound solution.

[0039] The formulations of other example...

Embodiment 3

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com