Low hydrogen type super-critical ferrite heat resistant steel electrode

A supercritical, ferritic technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of unsatisfactory performance and mechanical properties, unsatisfactory impact toughness, poor crack resistance, etc., to achieve excellent Good mechanical properties, good impact toughness and excellent crack resistance

Active Publication Date: 2014-10-29

WUHAN TEMO WELDING CONSUMABLES CO LTD

View PDF6 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In view of the above problems, the object of the present invention is to provide a low-hydrogen type supercritical ferritic heat-resistant steel electrode, which aims to solve the problem of unsatisfactory process performance and mechanical properties of the existing electrode for welding T / P91 steel, high diffusible hydrogen, and high resistance to welding. The technical problems of poor cracking and unsatisfactory impact toughness

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

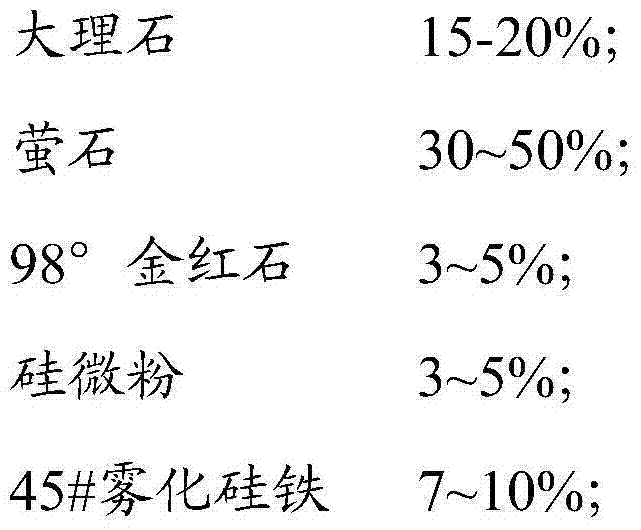

[0035] The composition and mass ratio of electrode coating and welding core are as follows:

[0036] Skin composition and ratio: 20% marble; 40% fluorite; 5% 98° rutile; 5% silicon powder; 10% 45# atomized ferrosilicon; 1% seaweed; 0.5%; the balance is iron powder.

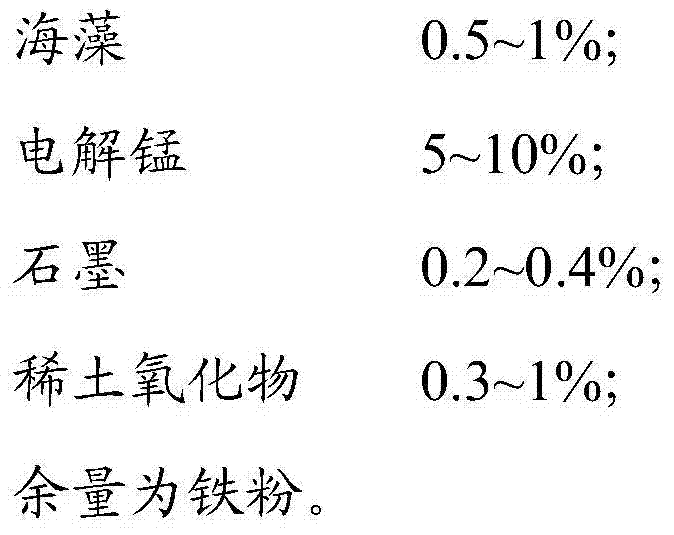

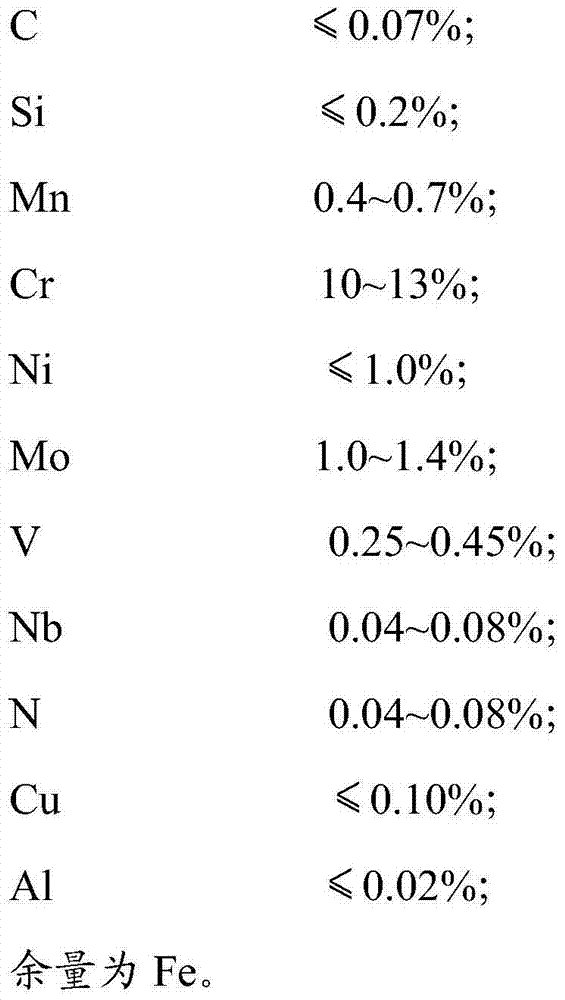

[0037] Weld core composition and ratio: C0.05%; Si0.2%; Mn0.7%; Cr12%; Ni0.05%; Mo1.4%; V0.4%; Nb0.04%; N0.07%; Cu0.05%; Al0.02%; the balance is iron.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of welding materials, and provides a low hydrogen type super-critical ferrite heat resistant steel electrode. A coating comprises, by weight, 15-20% of marble, 30-50% part of fluorite, 3-5% of rutile with purity being 98 percent, 3-5% of silica powder, 7-10% of 45# pulverization silicon iron, 0.5-1% of seaweed, 5-10% of electrolytic manganese, 0.2-0.4% of graphite, 0.3-1% of rare earth oxide, and the balance iron powder. According to the low hydrogen type super-critical ferrite heat resistant steel electrode, the ratio of the marble and the fluorite in the steel electrode coating is about 1: 2, the diffusible hydrogen content of a weld joint is reduced, the technical performance of the steel electrode is improved, the core wire component is microalloyed, the core wire tradition alloy component is adopted, the good mechanical performance is obtained, and the experience shows that the steel electrode is good in electric arc stability, impact toughness and crack resistance, good in welding technology and suitable for full-position welding of T / P91 steel, and the diffusible hydrogen reaches the ultralow hydrogen level.

Description

technical field [0001] The invention belongs to the technical field of welding materials, in particular to a low-hydrogen type supercritical ferrite heat-resistant steel welding rod. Background technique [0002] T / P91 steel is a new type of steel obtained by adding a small amount of niobium, vanadium and nitrogen microalloying on the basis of traditional 9Cr1Mo steel. Such compositions provide excellent long term high temperature creep strength. T / P91 steel is widely used in the construction of main structures such as boiler drums, steam pipes and steam turbine casings of coal-fired and power plants, and can also be used in smelting equipment in the petrochemical industry and coal liquefaction and gasification equipment. [0003] However, in the field of heat-resistant steel, the supporting T / P91 steel electrode has unsatisfactory technological and mechanical properties, high diffusible hydrogen, poor crack resistance, and unsatisfactory impact toughness. Contents of the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/365B23K35/368B23K35/30

CPCB23K35/0266B23K35/3086B23K35/3605B23K35/365

Inventor 田海成刘玉双韩海峰李磊张亚平

Owner WUHAN TEMO WELDING CONSUMABLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com