Silicon carbide mesoporous array material and manufacturing method of silicon carbide mesoporous array material

A silicon carbide mesoporous and array technology, which is applied in metal material coating process, gaseous chemical plating, manufacturing of microstructure devices, etc., can solve the problems of uneven longitudinal distribution, thickness of cap layer and transition layer, etc., and achieves convenient preparation. , Simplified preparation equipment, strong reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail

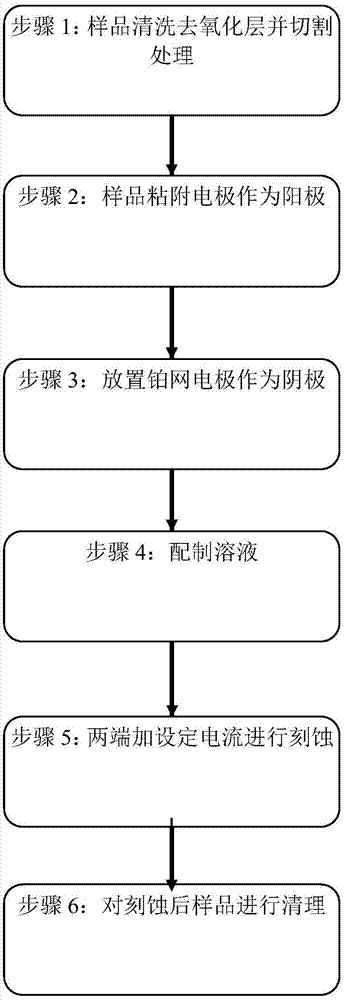

[0020] A preparation process of a mesoporous array based on a heavily doped n-type 4H-SiC substrate described in an embodiment of the present invention (such as figure 1 shown), including the following steps:

[0021] Step 1, prepare heavily doped n-type 4H-SiC pre-etched samples.

[0022] The sample is a wafer with a size of 100cm 2 , cut at 4°, polished on both sides, obtained after cleaning by strict semiconductor process and cut into 1.2cm×1.2cm square pieces by pre-etching samples, and then passed through hydrofluoric acid with a volume ratio of 1:1 ( 49%) and ethanol (99%) solution to remove the surface oxide layer.

[0023] Step 2, cut the dual-lead copper foil to an area of 1cm 2 square, and then uniformly adhered to the Si surface of the sample.

[0024] Step 3, fix the sample at the anode position of the etching tank, and place the platin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com