Polymer and resist compound having same polymer

A polymer and resist technology, applied in organic chemistry, photoengraving process of pattern surface, photosensitive materials for opto-mechanical equipment, etc., can solve problems such as corrosion resistance reduction, pattern cracking, and problem deterioration , to achieve excellent contrast, prevent thickness loss, and improve the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

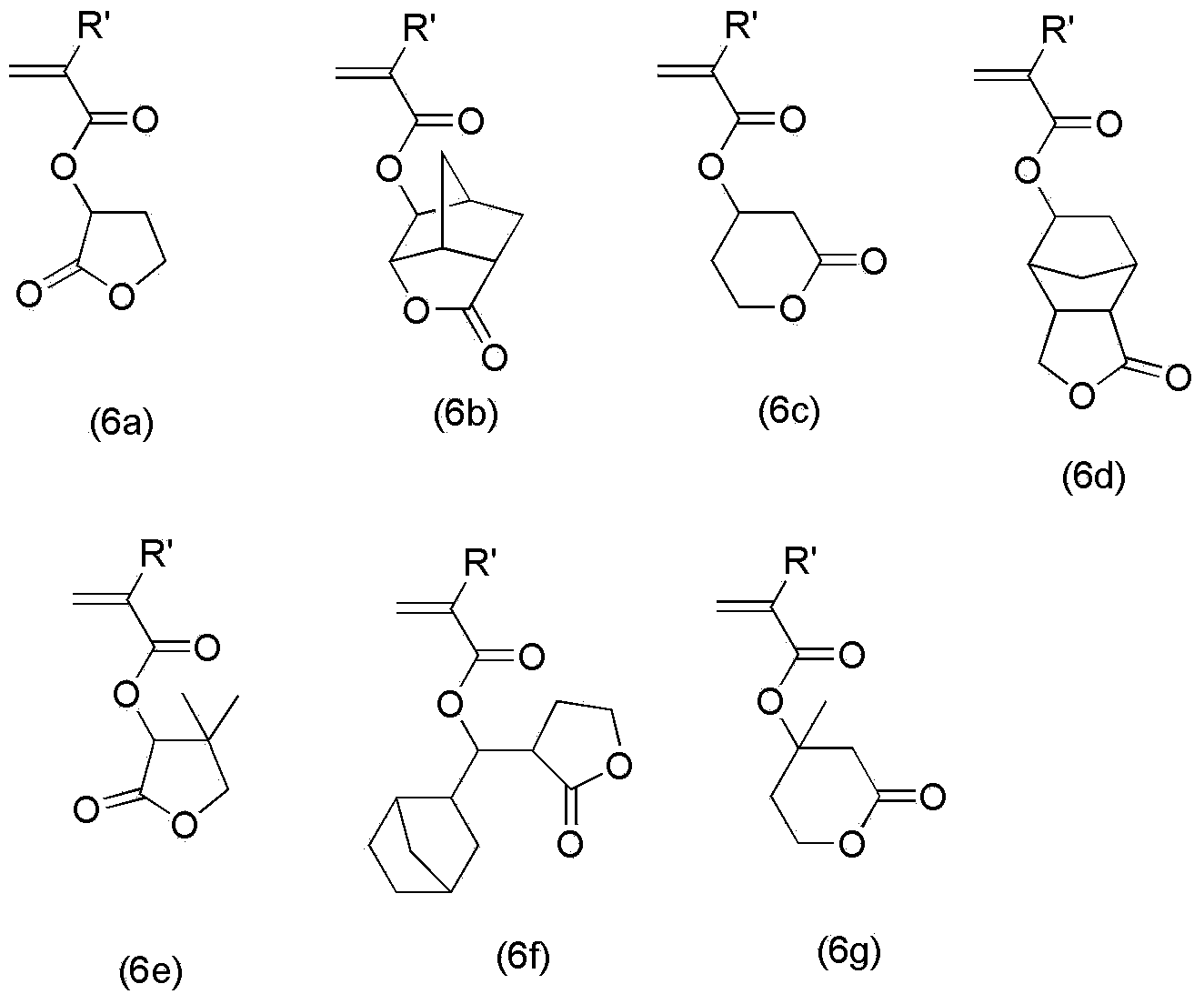

[0196] In a jacketed (jacket) reactor of 1L, the air in the reactor was purged with nitrogen, and under a nitrogen atmosphere, 52g of norbornene (norbornene), 43g of γ-butyrolactone acrylate ( γ-butyrolactone acrylate), 40 g of ethoxy ethyl methacrylate (ethoxy ethyl methacrylate) were dissolved in 405 g of 1,4-dioxane (1,4-dioxane). While stirring the obtained solution, 12.8 g of dimethyl azobisisobutyrate (DMAB, dimethyl azobis butyronitrile) was added as an initiator, and the temperature of the oil bath was gradually raised to 75° C. Stir at 75°C for 3 hours. After the reaction was completed, the temperature of the reaction solution was lowered to normal temperature, and the precipitation reaction was performed using n-hexane, followed by vacuum filtration. The obtained filtrate was dried at 50° C. for one day to obtain 105 g of a polymer (10a).

[0197]

[0198] (In the above formula, the molar ratio (a:c:b) of each repeating unit is 0.3:0.3:0.6)

[0199] The prepare...

Synthetic example 2

[0203] In a 1L jacketed (jacket) reactor, use nitrogen to purge the air in the reactor (purge), under a nitrogen atmosphere, 36g of ethoxyethyl methacrylate (ethoxyethyl methacrylate), 52g of Norbornane carbolactone methacrylate and 51 g of adamantine methacrylate were dissolved in 405 g of 1,4-dioxane. While stirring the obtained solution, 16 g of dimethyl azobisisobutyrate (DMAB, dimethyl azobis butyronitrile) was added as an initiator, and the temperature of the oil bath was slowly raised to 75° C. Stir at °C for 3 hours. After the reaction was completed, the temperature of the reaction solution was lowered to normal temperature, and the precipitation reaction was performed using n-hexane, followed by vacuum filtration. The obtained filtrate was dried at 50° C. for one day to obtain 123 g of a polymer (10b).

[0204]

[0205] (In the above formula, the molar ratio (a:c:d) of each repeating unit is 0.33:0.33:0.33)

[0206] The prepared polymer was measured by gas chrom...

Synthetic example 3

[0210] In a 1L jacket (jacket) reactor, use nitrogen to purge (purge) the air in the reactor, under nitrogen atmosphere, 38g of tetrahydrofuran methacrylate (tetrahydropyran methacrylate), 52g of norbornanyl carbon lactone Norbornane carbolactone methacrylate and 51 g of hydroxyadamantane methacrylate were dissolved in 405 g of 1,4-dioxane. While stirring the obtained solution, 16 g of dimethyl azobisisobutyrate (DMAB, dimethyl azobis butyronitrile) was added as an initiator, and the temperature of the oil bath was slowly raised to 75° C. Stir at °C for 3 hours. After the reaction was completed, the temperature of the reaction solution was lowered to normal temperature, and the precipitation reaction was performed using n-hexane, followed by vacuum filtration. The obtained filtrate was dried at 50° C. for one day to obtain 115 g of a polymer (10c).

[0211]

[0212] (In the above formula, the molar ratio (a:c:d) of each repeating unit is 0.33:0.33:0.33)

[0213] The prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com