Preparation method of calcium-strontium/gelatin biomimetic coating modified artificial ligament

An artificial ligament and gelatin technology, applied in the field of biomedicine, can solve the problems of poor repeatability of experimental results, low rate of osteogenic differentiation, uneven coating, etc., to improve biocompatibility and increase the chance of tendon-bone healing , Facilitate the effect of cell adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

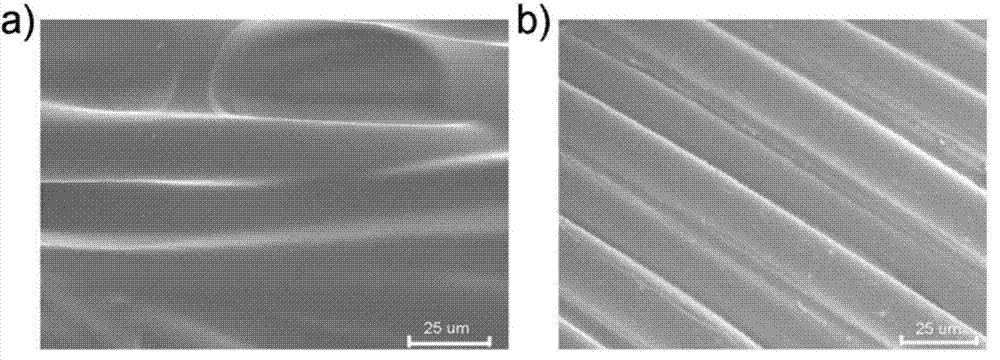

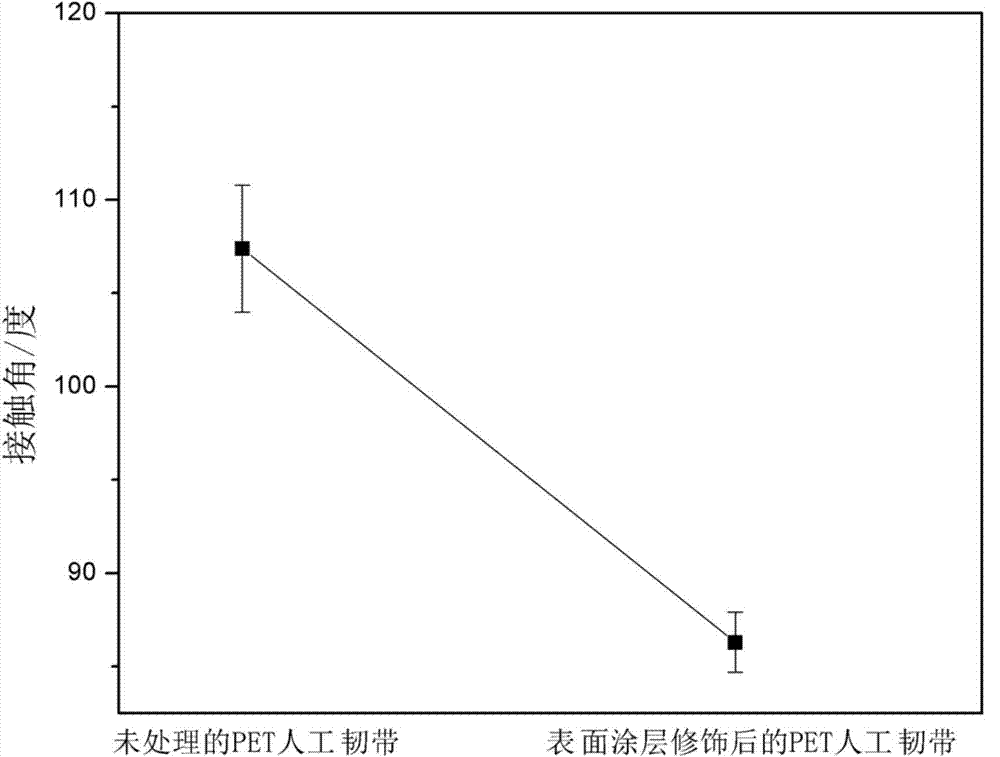

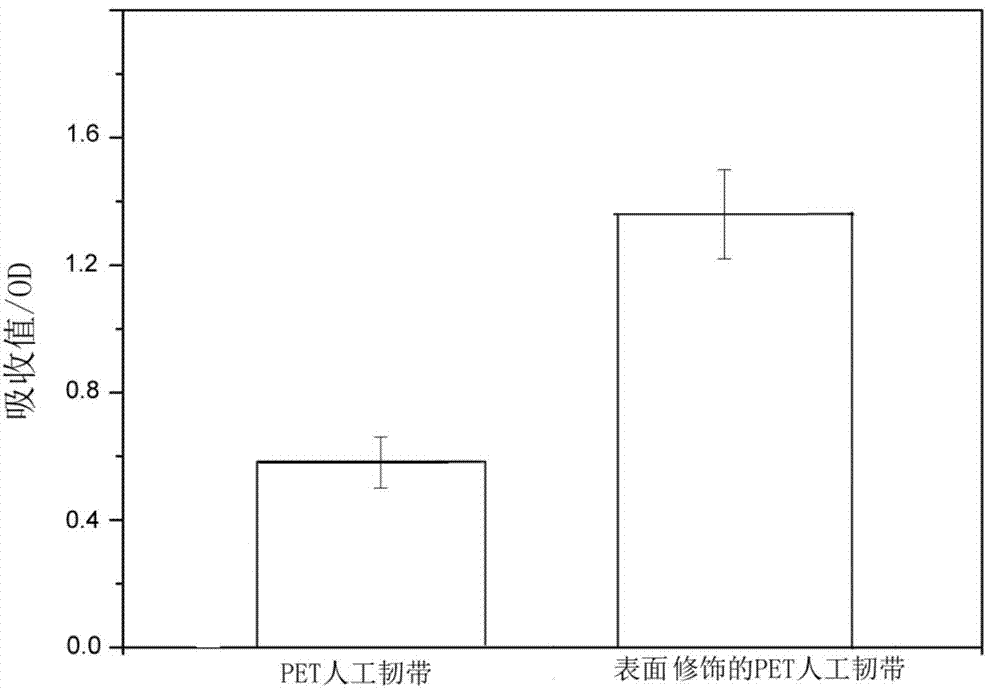

Image

Examples

Embodiment 1

[0037] Under background vacuum 5 x 10 10-2 Pa, under the condition of power 200W, use H 2 Plasma treated the PET artificial ligament for 8 minutes, then soaked in 10mM acrylic acid monomer grafting solution for 2 hours, and finally washed with pure water and dried in vacuum for later use;

[0038] Add 2g of bone gelatin particles to 100ml deionized water to swell, then heat to 55°C to form a 2wt.% bone gelatin solution with a molar concentration of ; then add 6ml of 40mM CaCO 3 and 6ml 20mM SrNO 3Add it to the gelatin solution, adjust the pH value to 7, and stir at 25°C for 10 minutes to obtain a uniformly mixed solution; soak the pretreated artificial ligament in this mixed solution to fully combine the free Ca and Sr ions and gelatin with the ligament , take the ligament out of the filter paper to dry, and finally soak in 500ml 60mM freshly prepared Na 2 HPO 4 The solution was irradiated by sunlight for 20 minutes, and the above steps were repeated 20 times to obtain a n...

Embodiment 2

[0044] 8 x 10 in background vacuum 10-2 Pa, Ar under the condition of power 400W 2 Plasma treated the PET artificial ligament for 20 minutes, then soaked in 100mM polyethylene glycol monomer grafting solution for 3 hours, and finally washed with pure water and dried in vacuum for later use;

[0045] Add 10 g of bone gelatin particles to 100 ml of deionized water to swell, then heat to 50 ° C to form a 10% bone gelatin solution, and then add 6 ml of 120 mM CaCO 3 Add 6ml of 30mM strontium dichloride to the gelatin solution, adjust the pH value to 8, and stir for 20 minutes at 25 degrees Celsius to obtain a uniformly mixed solution; soak the pretreated artificial ligament in the mixed solution, and stir for 45 minutes to react. Make the free Ca and Sr ions and gelatin fully combined with the ligament, take out the filter paper to dry the ligament, and finally soak it in 600ml 90mM freshly prepared sodium phosphate solution, expose it to simulated sunlight for 30min, and repeat ...

Embodiment 3

[0047] Add 10g of bone gelatin particles to 200ml of deionized water to swell, then heat to 60°C to form a 5% bone gelatin solution, add 6ml of 300mM mixed solution of calcium nitrate and calcium carbonate, and 6ml of mixed solution of 50mM strontium nitrate and strontium chloride In 5% gelatin solution, adjust the pH value to 7.4, stir at 25°C for 30 minutes to obtain a well-mixed solution; then vacuum 7×10 10-2 Pa, under the condition of power 350W, use H 2 Plasma treated the PET artificial ligament for 15 minutes, then soaked it in 55mM heparin monomer grafting solution for 6 hours, and finally washed it with pure water and dried it in vacuum; soaked the pretreated artificial ligament in the mixed solution, stirred and reacted for 50 minutes, so that the free Ca and Sr ions and gelatin are fully combined with the ligament, the ligament is taken out of the filter paper to dry, and finally soaked in 250ml 75mM freshly prepared mixed solution of potassium dihydrogen phosphate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com