Preparing method of metal-carbide-containing multi-layer multi-component composite material

A multi-layer composite material, metal carbide technology, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of difficult multi-layer multi-component composite materials, high raw material requirements, and complexity. , to achieve the effect of easy expansion of production, simple preparation process, and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

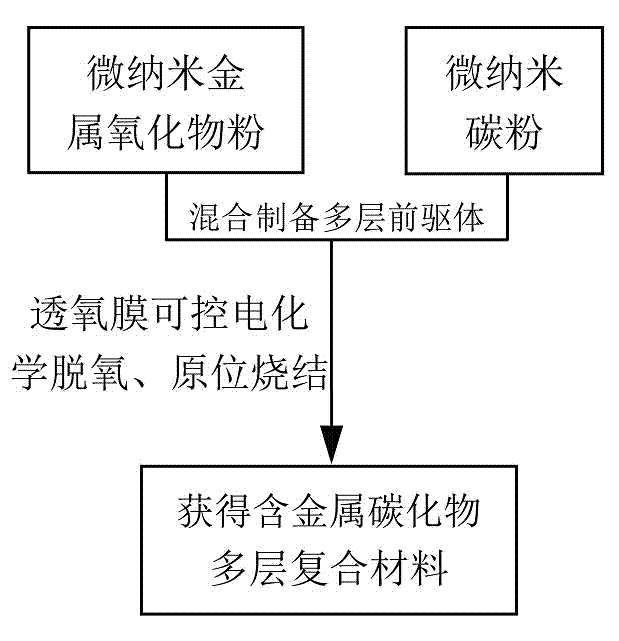

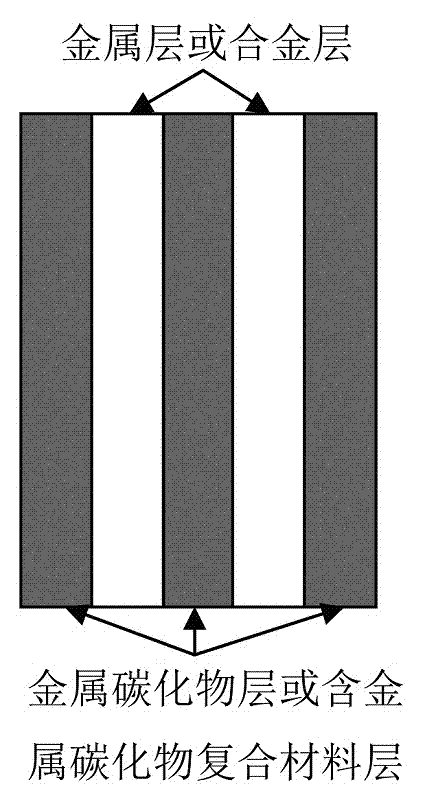

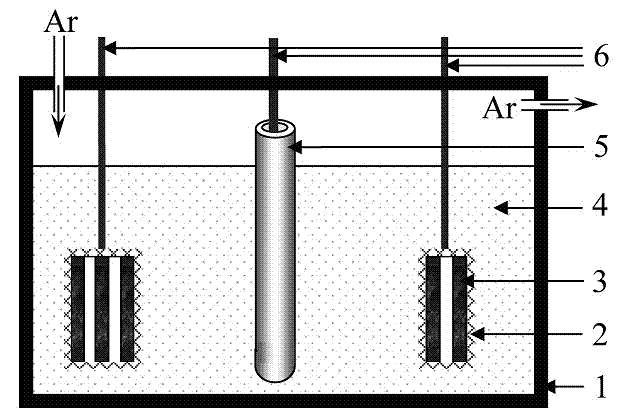

[0030] This embodiment according to figure 1 The simple process shown is carried out, taking the preparation of a three-layer metal carbide multi-component composite material as an example, the schematic diagram of the multi-layer composite material is shown in figure 2shown. First, take the preparation of a three-layer composite material (TiC|Ti|TiC) of titanium carbide and titanium as an example. Titanium dioxide and carbon powder were mixed according to Ti:C = 1:1, and 2% by weight polyvinyl butyral binder was added and then ball-milled to obtain a uniform powder as the TiC layer precursor powder. TiO 2 / C powder and pure TiO 2 powder according to TiO 2 / C|TiO 2 |TiO 2 / C sequentially pressed into a three-layer precursor 3, and then the pressed three-layer precursor 3 was sintered in a high-purity argon gas protection at 1100°C for 2 hours. The sintered precursor was wrapped with foam nickel 2 and wrapped with iron-chromium-aluminum wire to make a three-layer precur...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, especially in that:

[0033] In this embodiment, five layers of Ti 5 Si 3 / TiC|Ti|Ti 5 Si 3 / TiC|Ti|Ti 5 Si 3 / TiC composites as an example. Firstly, titanium dioxide, silicon dioxide and carbon powder are mixed according to the target layer product Ti 5 Si 3 The stoichiometric ratio of / TiC is mixed, and after adding an appropriate amount of binder, the ball mill is mixed to obtain Ti 5 Si 3 The precursor raw material of the / TiC layer; the precursor raw material of the metal titanium layer is pure titanium dioxide powder; 2 / SiO 2 / C|TiO 2 |TiO 2 / SiO 2 / C|TiO 2 |TiO 2 / SiO 2 The / C layer sequence is sequentially pressed to form a five-layer precursor. The pressed five-layer precursor was sintered at 1300°C for 2 hours under an inert atmosphere, and then the sintered precursor was wrapped with foamed nickel and wrapped with iron-chromium-aluminum wire to make a cathode. Place the prepared cathode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com