Method for manufacturing photoelectric detector based on integrated chip with alloy semiconductor nano-structure

A photodetector and nanostructure technology, applied in the field of photodetection, can solve the problems of uneven response and high cost of photodetectors, and achieve the effects of high-sensitivity photoconductive detection, low production cost, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The fabrication of a photodetector based on an alloy semiconductor nanostructure integrated substrate, the specific steps are as follows:

[0033] 1. Stir cadmium sulfide and cadmium selenide evenly in a mortar for 10 minutes according to the molar ratio of 1:1; clean the silicon wafer with absolute ethanol in an ultrasonic cleaner for 10 minutes, and after drying, use an ion sputtering instrument to plate gold for 60 seconds , Clean small porcelain containers and high temperature resistant glass containers for later use. Then put the mixture of CdS (cadmium sulfide) and CdSe (cadmium selenide) into the porcelain container, and place the porcelain container in the center of the high temperature resistant glass container. Put a gold-plated silicon wafer in another porcelain container, place it downstream of the airflow of the high-temperature-resistant glass container, 11 cm away from the center of the high-temperature-resistant glass container. Put the high-temperature...

Embodiment 2

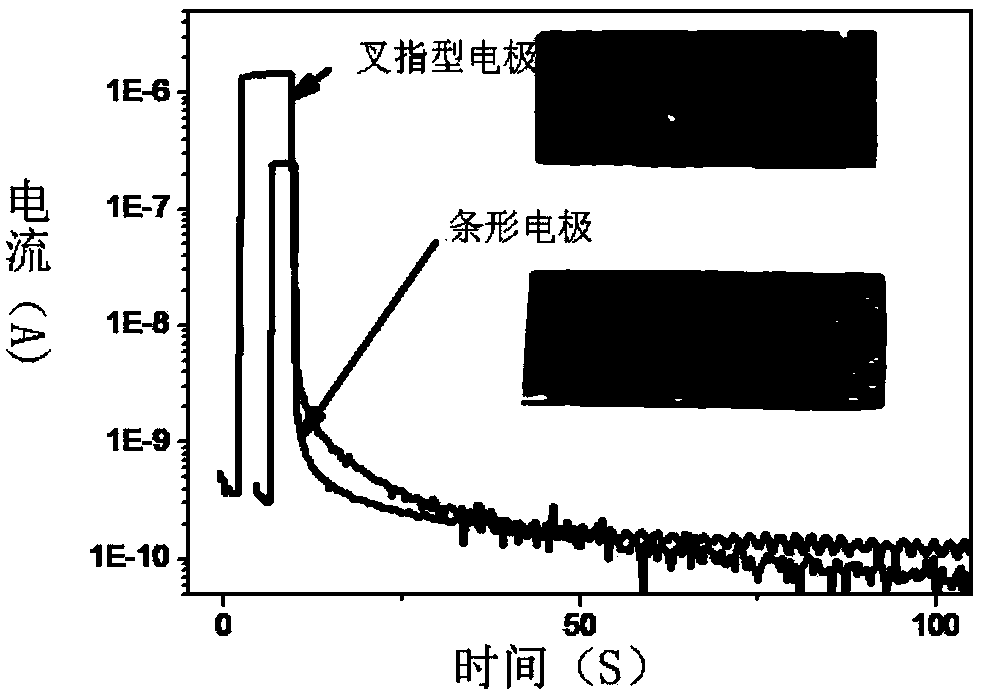

[0039] Based on the semiconductor test system (Keithley-4200), the photoconductive properties of CdSSe alloy nanostructure substrates plated with different electrode materials, different electrode thicknesses, and different electrode shapes with gradient components under the irradiation of polychromatic light (white light), and The change of photocurrent. The steps are:

[0040]1. Stir cadmium sulfide and cadmium selenide uniformly in a mortar for 15 minutes according to the molar ratio of 1:1; silicon wafer (n-type silicon, crystal orientation ) is cleaned in an ultrasonic cleaner with absolute ethanol for 10 minutes. Minutes, after drying, gold-plate with ion sputtering device for 60 seconds, and clean small porcelain containers and high-temperature-resistant glass containers for later use. Then put the mixture of CdS (cadmium sulfide) and CdSe (cadmium selenide) into the porcelain container, and place the porcelain container in the center of the high temperature resistant ...

Embodiment 3

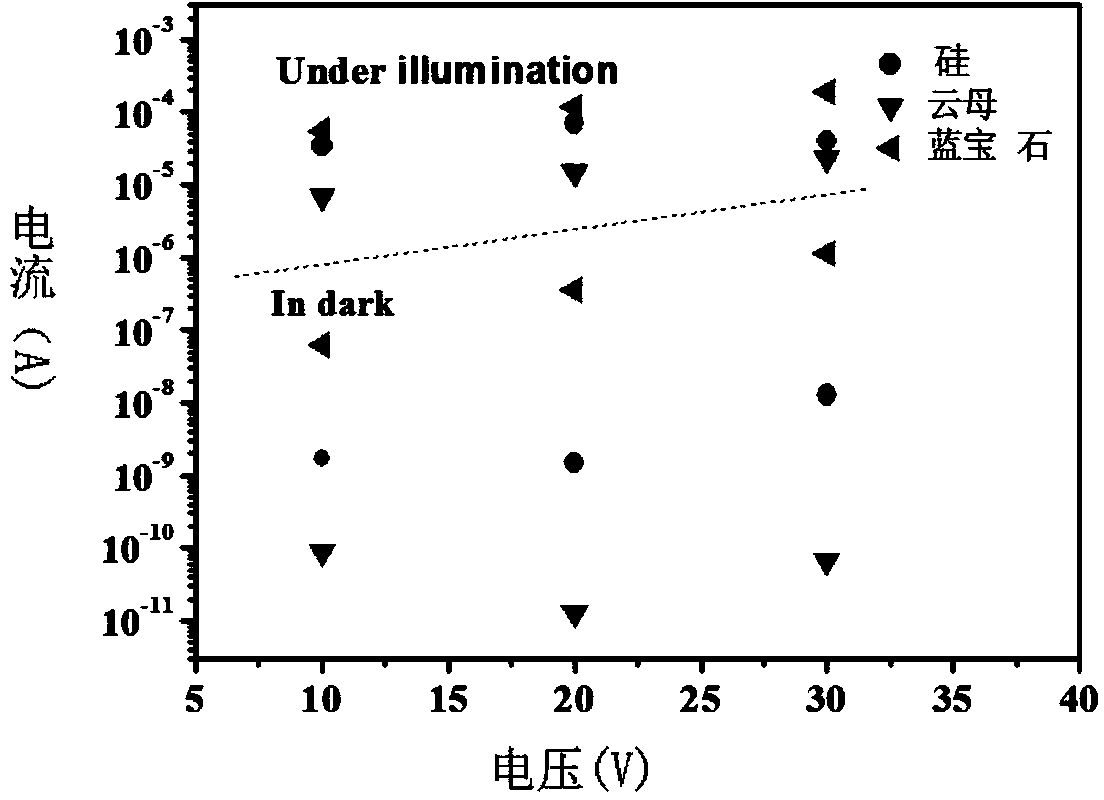

[0047] Based on the semiconductor test system, the alloy nanostructures grown under different substrates were tested, focusing on the photoconductive properties of the nanostructures synthesized on various substrates, and the change of photocurrent / dark current. The steps are:

[0048] 1. Stir cadmium sulfide and cadmium selenide uniformly in a mortar for 20 minutes according to the molar ratio of 1:1; different thicknesses and different types of single substrate [silicon wafer (n-type silicon, crystal orientation ), Gem slices, mica slices] were cleaned in an ultrasonic cleaner with absolute ethanol for 10 minutes, and after drying, they were gold-plated with an ion sputtering instrument for 60 seconds, and the small porcelain containers and high-temperature-resistant glass containers were cleaned for later use. Then put the mixture of CdS (cadmium sulfide) and CdSe (cadmium selenide) into the porcelain container, and place the porcelain container in the center of the high te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com