A kind of low-carbon alkane dehydrogenation catalyst containing skeleton silver and preparation method thereof

A dehydrogenation catalyst, a technology of low-carbon alkanes, applied in the directions of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve the problems of low catalyst stability and rapid deactivation, and achieve excellent catalyst activity stability, The effect of preventing crystal phase transformation and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

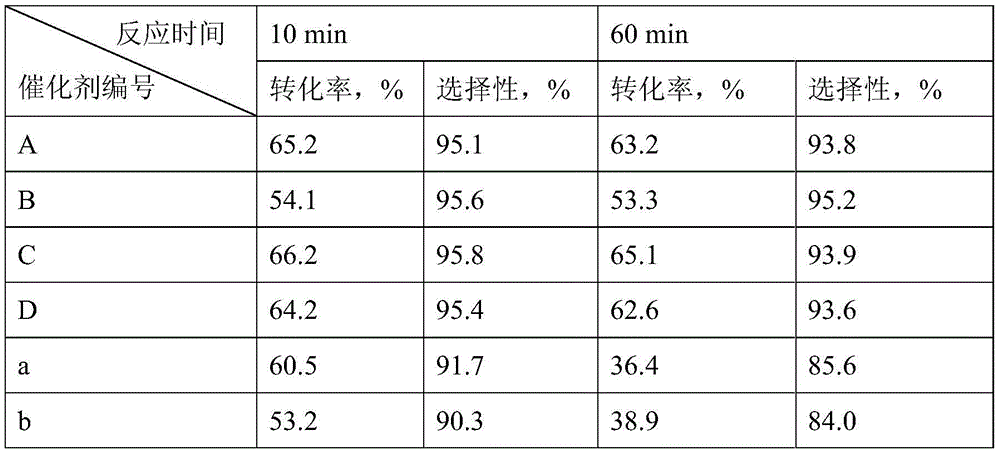

Examples

Embodiment 1

[0041] Aluminum hydroxide preparation. Take 3.5g of silver nitrate and dissolve it in 1L of 20% dilute nitric acid, and mix with Al 2 o 3 The concentration is 200g / L of sodium metaaluminate solution for neutralization, the neutralization temperature is 60°C, and the neutralization pH is 8.5. Aging for 1 hour after neutralization, then aging the slurry at pH 9.5 and temperature 60°C for 0.5 hour, filtering and washing, drying at 120°C for 8 hours, and crushing to obtain aluminum hydroxide powder A1.

[0042] Carrier Al 2 o 3 preparation. Mix a certain amount of aluminum hydroxide powder A1 with 8% of the mass fraction of aluminum oxide powder and turnip powder, then add citric acid with a mass concentration of 6% and dilute nitric acid with a mass concentration of 20% for kneading, kneading The time is 30 minutes, and finally it is molded on a molding machine. After the molded carrier is aired at room temperature for 8 hours, it is then dried at 120°C for 4 hours. The drie...

Embodiment 2

[0047] Aluminum hydroxide preparation. Dissolve 5.5g of silver nitrate and 600g of aluminum nitrate into 1L of solution, and mix with Al 2 o 3 The concentration is 200g / L of sodium metaaluminate solution for neutralization, the neutralization temperature is 30°C, and the neutralization pH is 10. Aging for 1 hour after neutralization, then aging the slurry for 1.5 hours at a pH of 10.5 and a temperature of 80°C, filtering and washing, drying at 120°C for 8 hours, and pulverizing to obtain aluminum hydroxide powder A2.

[0048] Carrier Al 2 o 3 The preparation was the same as in Example 1, using aluminum hydroxide A2 as the alumina raw material, and the water absorption rate of the prepared carrier was 57.9%.

[0049] Weigh 18g of chromium trioxide, 2.8g of potassium nitrate, and 3.2g of calcium nitrate, add 30ml of deionized water to make an impregnation solution, and weigh the carrier Al prepared above. 2 o 3 20g was supersaturated impregnated for 1 hour, then the impreg...

Embodiment 3

[0052] Aluminum hydroxide preparation. Dissolve 0.5g of silver nitrate and 800g of aluminum sulfate into 1L of solution, neutralize with 20% sodium hydroxide solution, the neutralization temperature is 40°C, and the neutralization pH is 6.5. After neutralization, the slurry was aged for 2 hours, and then the slurry was aged for 2.5 hours at a pH of 11.5 and a temperature of 50° C., filtered and washed, dried at 120° C. for 8 hours, and crushed to obtain aluminum hydroxide powder A3.

[0053] Carrier Al 2 o 3 The preparation was the same as in Example 1, using aluminum hydroxide A3 as the alumina raw material, and the water absorption rate of the prepared carrier was 59.4%.

[0054] Weigh 18g of chromium trioxide, 3.0g of magnesium nitrate, 2.9g of copper nitrate, add 30ml of deionized water to make an impregnation solution, weigh the carrier Al prepared above 2 o 3 20g was subjected to supersaturated impregnation for 1 hour, then the impregnated carrier was taken out, aire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com