Catalyst and method for preparing ethanol

A catalyst and ethanol technology, applied in the field of catalytic chemistry, can solve the problems of large consumption, low ethanol selectivity, and high requirements for reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

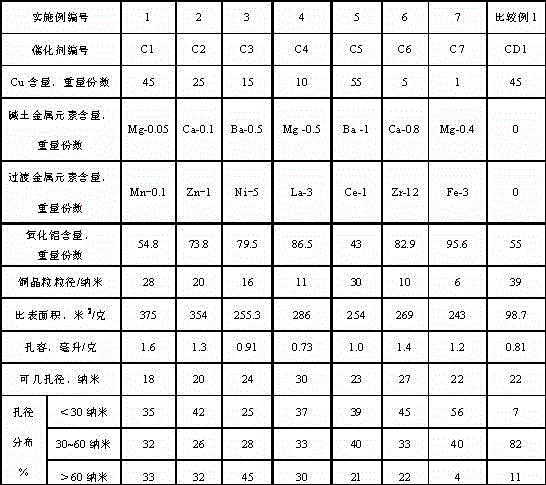

[0034] Weigh 29 grams of pseudo-boehmite, 110 grams of γ-alumina, and 2.7 grams of scallop powder, mix them, add 1.4 grams of polyvinyl alcohol solution with a mass concentration of 5%, 1.4 grams of nitric acid, and 1.0 grams of magnesium nitrate dihydrate in an aqueous solution of 200 milliliter, extruded into a clover with a diameter of Ф2.5 mm, dried at 50°C for 24 hours and then calcined at 1000°C for 4 hours to obtain an alumina carrier A1 with a composite pore structure. Pre-soak the carrier with deionized water, then drain. Weigh 428 grams of copper nitrate and 1.14 grams of manganese nitrate tetrahydrate to make a 0.8M solution, and impregnate until the impregnating solution is colorless, drain, dry at 120°C for 4 hours, and roast at 450°C for 6 hours to obtain catalyst C1. The catalyst composition, specific surface area, pore volume, and pore distribution are shown in Table 1.

[0035]

Embodiment 2

[0037] Weigh 116 grams of pseudo-boehmite, 258 grams of γ-alumina, and 7.4 grams of asparagus powder, mix them, add 3.7 grams of polyvinyl alcohol solution with a mass concentration of 5%, 3.7 grams of nitric acid, and 500 grams of aqueous solution of 1.0 grams of calcium nitrate tetrahydrate. milliliter, extruded into a clover with a diameter of Ф2.5 mm, dried at 50°C for 24 hours and then calcined at 1000°C for 4 hours to obtain an alumina carrier A2 with a composite pore structure. Pre-soak the carrier with deionized water, then drain. Weigh 475.6 grams of copper nitrate and 22.9 grams of zinc nitrate hexahydrate to make a 0.8M solution, impregnate until the impregnation solution is colorless, drain, dry at 120°C for 4 hours, and roast at 450°C for 6 hours to obtain catalyst C2. The catalyst composition, specific surface area, pore volume, and pore distribution are shown in Table 1.

[0038]

Embodiment 3

[0040] Take by weighing 111.3 grams of pseudo-boehmite, 47.7 grams of gamma alumina, 4.8 grams of turnip powder, mix, add 3.2 grams of polyvinyl alcohol solution with a mass concentration of 5%, 3.5 grams of nitric acid, and 500 milliliters of an aqueous solution of 1.9 grams of barium nitrate, Extruded into a clover with a diameter of Ф2.5 mm, the wet strip was dried at 50°C for 24 hours and then calcined at 1000°C for 4 hours to obtain an alumina carrier A3 with a composite pore structure. Pre-impregnate the carrier with deionized water, then drain the water, weigh 114.1 grams of copper nitrate and 49.5 grams of nickel nitrate hexahydrate to prepare a 0.8M solution, and impregnate until the impregnating solution is colorless, drain, and dry at 120°C for 4 hours; 450 ℃ for 6 hours to prepare catalyst C3. The catalyst composition, specific surface area, pore volume, and pore distribution are shown in Table 1.

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com