Polyvinylidene fluoride preparation method

A technology selected from polyvinylidene fluoride, which is applied in the field of preparation of fluorine-containing polymers, can solve the problems of high system pressure, high reaction risk, and long time consumption, and achieve the effect of reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

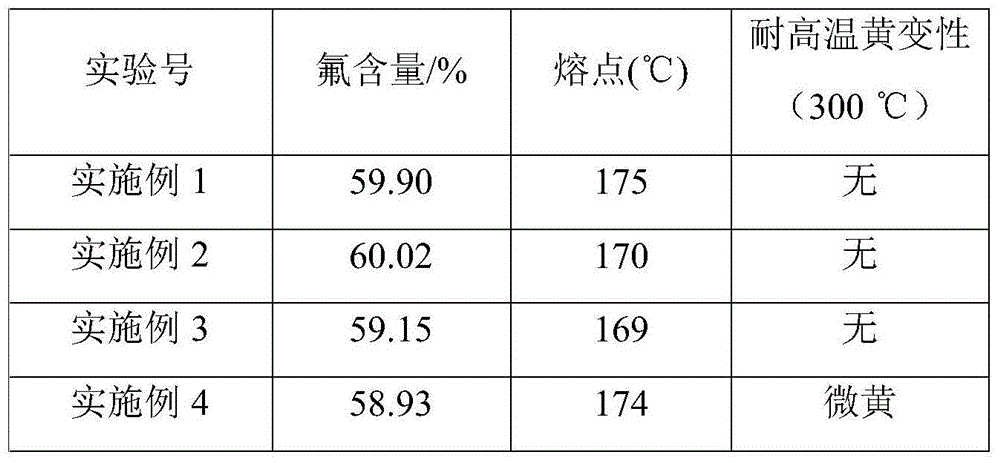

Examples

Embodiment 1

[0031] In a 5L vertical stainless steel jacketed and stirred polymerization reactor, the nitrogen was evacuated 5 times to detect that the oxygen content in the reactor was lower than 20ppm, and the system was filled with nitrogen to slightly positive pressure, and the temperature of the system was controlled at -2°C. Perfluoro(2-ethoxy)propionyl chloride (CF 3 CF 2 OCF 2 CF 2 COCl) trifluorotrichloroethane solution 100ml (concentration is 6%), stirring speed is 200rpm. Slowly add 12.27 g of a pre-configured mixed solution of NaOH and 30% hydrogen peroxide to the system, which contains 0.8 g of NaOH and 2.27 g of 30% hydrogen peroxide. Control the temperature of the system at -10°C and stir for 0.5h. 2.7 L of deionized water dissolved in 3.1 g of isopropylcyclopentane and 4.1 g of methylcellulose cooled at 2°C was passed into the system. The stirring speed was increased to 600 rpm, and 600 g of liquid monomer vinylidene fluoride was introduced into the system. The temper...

Embodiment 2

[0033] In a 5L vertical stainless steel jacketed and stirred polymerization reactor, the nitrogen was evacuated and replaced 5 times to check that the oxygen content reached the standard, so that the system pressure was slightly positive, and the system temperature was controlled at -5°C. into the dissolved F(CF 2 CF 2 OCF 2 ) 4 COCl trifluorotrichloroethane solution 100ml (concentration: 15%), the stirring speed is 200rpm. Slowly add 12.27 g of a pre-configured mixed solution of NaOH and 30% hydrogen peroxide to the system, which contains 0.8 g of NaOH and 2.27 g of 30% hydrogen peroxide. The system was stirred at -5°C for 1 h. 2.7 L of deionized water dissolved in 3.1 g of isopropylcyclopentane and 4.1 g of methylcellulose cooled at 2°C was passed into the system. The stirring speed was increased to 600 rpm, and 600 g of liquid monomer vinylidene fluoride was introduced into the system. The temperature was raised to 20°C within half an hour for the reaction, and the re...

Embodiment 3

[0035] In a 5L vertical stainless steel jacketed and stirred polymerization reactor, the nitrogen was evacuated and replaced 5 times to check that the oxygen content reached the standard, so that the system pressure was slightly positive, and the system temperature was controlled at 0°C. into the dissolved CF 2 CF 2 COCl trifluorotrichloroethane solution 100ml (concentration: 3.5%), stirring speed is 200rpm. Slowly add 12.27 g of a pre-configured mixed solution of NaOH and 30% hydrogen peroxide to the system, which contains 1.12 g of KOH and 2.27 g of 30% hydrogen peroxide. The system was stirred at -5°C for 1 h. 2.7 L of deionized water dissolved in 3.1 g of isopropylcyclopentane and 4.1 g of methylcellulose cooled at 2°C was passed into the system. The stirring speed was increased to 600 rpm, and 600 g of liquid monomer vinylidene fluoride was introduced into the system. The temperature was raised to 30°C within half an hour for the reaction, the temperature was raised t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com