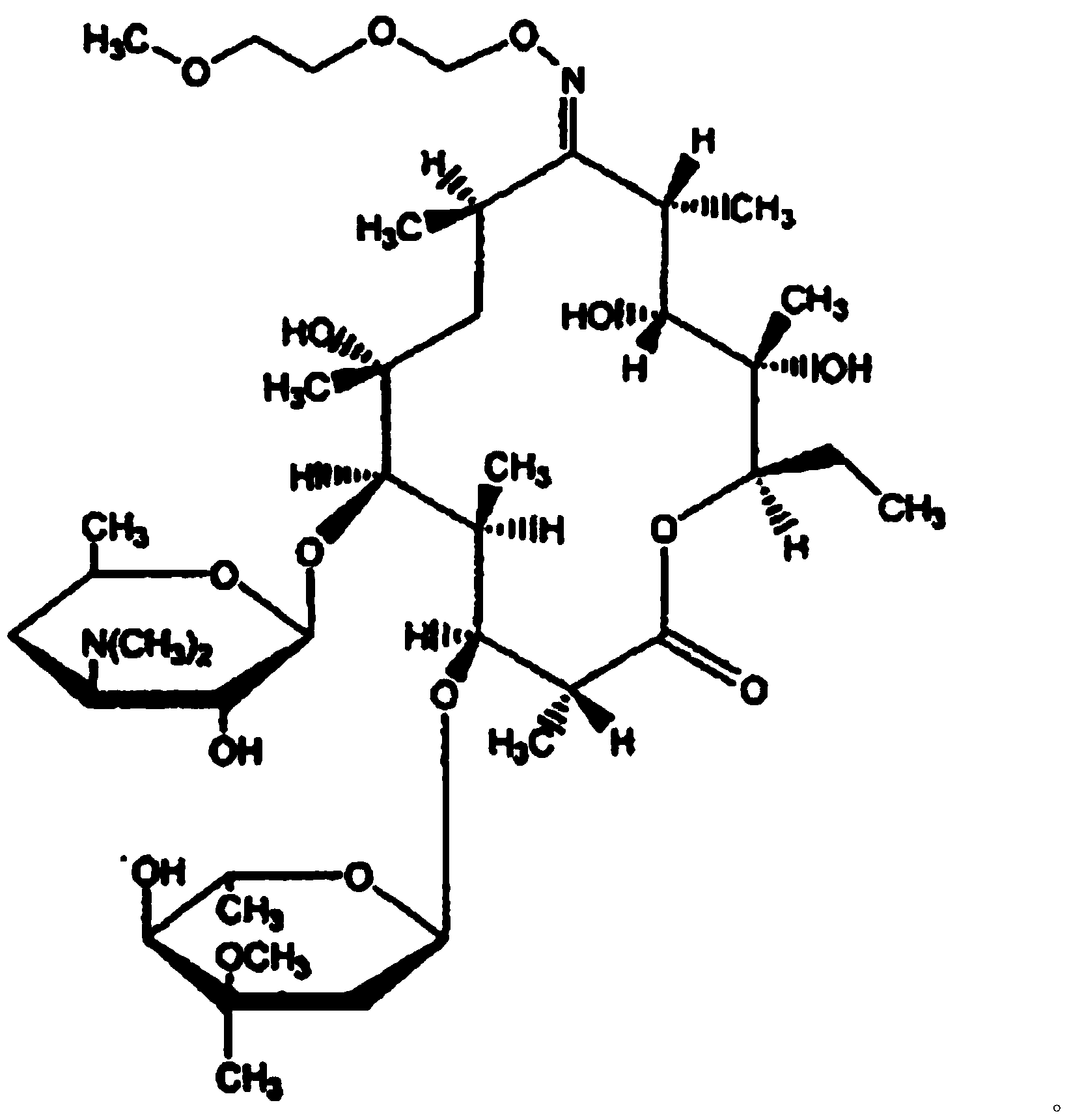

Roxithromycin refining method

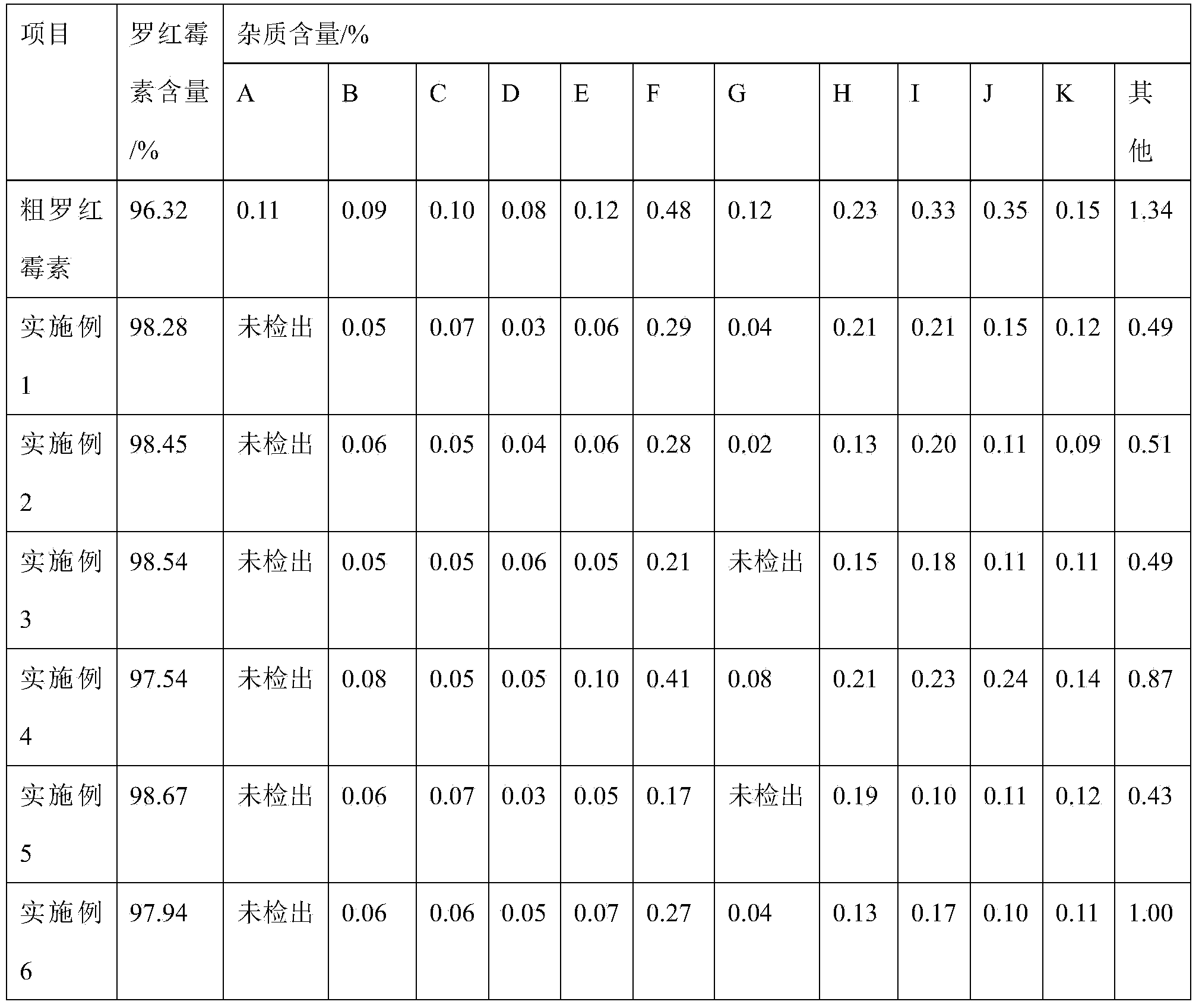

A technology of roxithromycin and refining method, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems affecting the stability and efficacy of roxithromycin, the comprehensive removal rate of impurities is not high, Problems such as low product quality and yield, to achieve the effect of good impurity removal effect, good appearance and color, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The refining method of the roxithromycin of the present embodiment may further comprise the steps:

[0035] 1) Disperse 100g of crude roxithromycin in a mixed solvent formed by mixing 50ml of methanol and 50ml of acetone, heat to 50°C and dissolve until clear to obtain a mixture;

[0036] 2) Slowly cool the mixture obtained in step 1) until the crystals are precipitated, then keep it warm at -5°C for 3 hours and stir to fully precipitate the crystals, filter, and use a mixed solvent at 0°C (this mixed solvent is the same as that used in step 1) Mixed solvent is the same), wash the solid, and dry at 50°C to obtain 94.55g of refined roxithromycin.

[0037] The mass yield of the purified roxithromycin obtained in the present embodiment is 94.55%.

Embodiment 2

[0039] The refining method of the roxithromycin of the present embodiment may further comprise the steps:

[0040] 1) Disperse 100g of crude roxithromycin in a mixed solvent formed by mixing 50ml of ethanol and 450ml of acetone, heat to 60°C and dissolve until clear to obtain a mixture;

[0041] 2) Slowly cool the mixture obtained in step 1) until the crystals are precipitated, then keep it warm at -20°C for 1.5 hours and stir to fully precipitate the crystals, filter, and use a mixed solvent at 5°C (this mixed solvent and step 1) The same mixed solvent used) washed the solid and dried at 55°C to obtain 85.78g of refined roxithromycin.

[0042] The mass yield of the purified roxithromycin obtained in the present embodiment is 85.78%.

Embodiment 3

[0044] The refining method of the roxithromycin of the present embodiment may further comprise the steps:

[0045] 1) Disperse 100g of crude roxithromycin in a mixed solvent formed by mixing 900ml of ethanol and 100ml of acetone, heat to 65°C and dissolve until clear to obtain a mixture;

[0046] 2) Slowly cool the mixture obtained in step 1) until the crystals are precipitated, then keep it warm at -10°C for 2 hours and stir to fully precipitate the crystals, then filter and use a mixed solvent at 5°C (this mixed solvent is the same as that used in step 1) Mixed solvent is the same), wash the solid, and dry at 65°C to obtain 88.74g of refined roxithromycin.

[0047] The mass yield of the purified roxithromycin obtained in the present embodiment is 88.74%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com