Separation and purification method of N(2)-L-alanyl-L-glutamine

A technology of dipeptide and purification method, which is applied in the direction of peptides, etc., can solve the problems of high cost, low yield and purity, and achieve the effects of simplifying production methods, high product purity, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

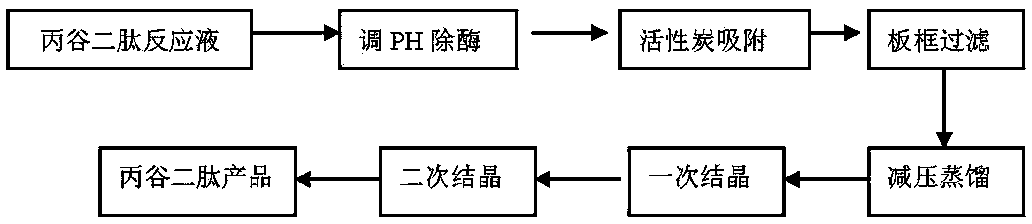

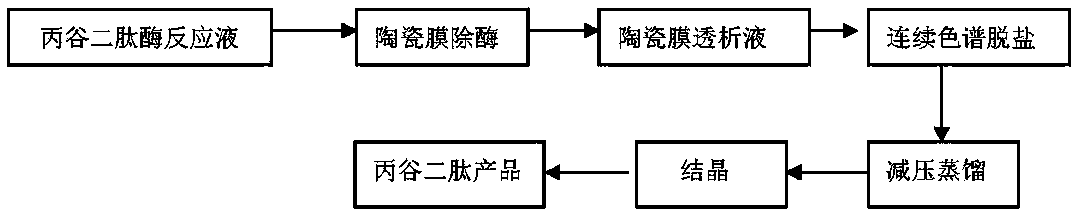

Method used

Image

Examples

Embodiment 1

[0017] In the prepared CG dipeptidase reaction liquid, the CG dipeptide mass fraction was 43.5%, and the sodium chloride mass fraction was 9.7%; after being filtered through a 50nm ceramic membrane, it was filled with a sodium-type strong acid ion exchange resin at a diameter-to-height ratio of 1:15, and the column temperature was 25 ℃, feed amount 0.1bv, constant temperature chromatographic separation, elution with distilled water, control column temperature 25 ℃ elution flow rate 0.5bv.h, collect the eluent and residual liquid respectively, the purity of glucodipeptide in the eluent is 96.8%, the concentration 35.2%, by distillation under reduced pressure, and then crystallized to obtain the dipeptide product, the yield is greater than 98.9%; the purity of sodium chloride in the residual liquid is 99.1%, and the concentration is 5.2%.

Embodiment 2

[0019] In the prepared CG dipeptidase reaction solution, the CG dipeptide mass fraction was 47.4%, and the sodium chloride mass fraction was 10.5%. After filtering through a 20nm ceramic membrane, the sodium-type strongly acidic ion exchange resin was filled with a diameter-to-height ratio of 1:20. 25°C, feed amount 0.5bv, constant temperature chromatographic separation, elution with distilled water, control column temperature 25°C elution flow rate 0.4bv.h, collect the eluent and residual liquid respectively, the purity of glucodipeptide in the eluent is 97.8%, Concentration of 37.5%, by distillation under reduced pressure, and then crystallization to obtain the product of dipeptide, the yield is greater than 98.5%; the purity of sodium chloride in the residual liquid is 97.8%, and the concentration is 7.2%.

Embodiment 3

[0021] In the obtained CG dipeptidase reaction solution, the CG dipeptide mass fraction was 44.4%, and the sodium chloride mass fraction was 8.5%,; after being filtered through a 100 μm ceramic membrane, the sodium-type strong acid ion exchange resin was filled with a diameter-to-height ratio of 1:50, and the column temperature 25°C, feed amount 1bv, constant temperature chromatographic separation, elution with distilled water, control column temperature 25°C elution flow rate 0.5bv.h, collect eluent and residual liquid respectively, distill under reduced pressure, and then crystallize, that is To obtain the dipeptide product of glucoside, the yield is greater than 97.5%; the purity of sodium chloride in the residual liquid is 98.9%, and the concentration is 6.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com