Graphical method for graphene thin film, functional device and application of graphene thin film

A technology of graphene film and functional devices, which is applied in the manufacture of semiconductor/solid-state devices, instruments, electrical components, etc. It can solve the problems of non-positioning voids, inability to realize arbitrary cutting of graphene, and deterioration of film performance, so as to prevent non-positioning Defects, avoiding the problem of rough edges of graphics, and the effect of convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

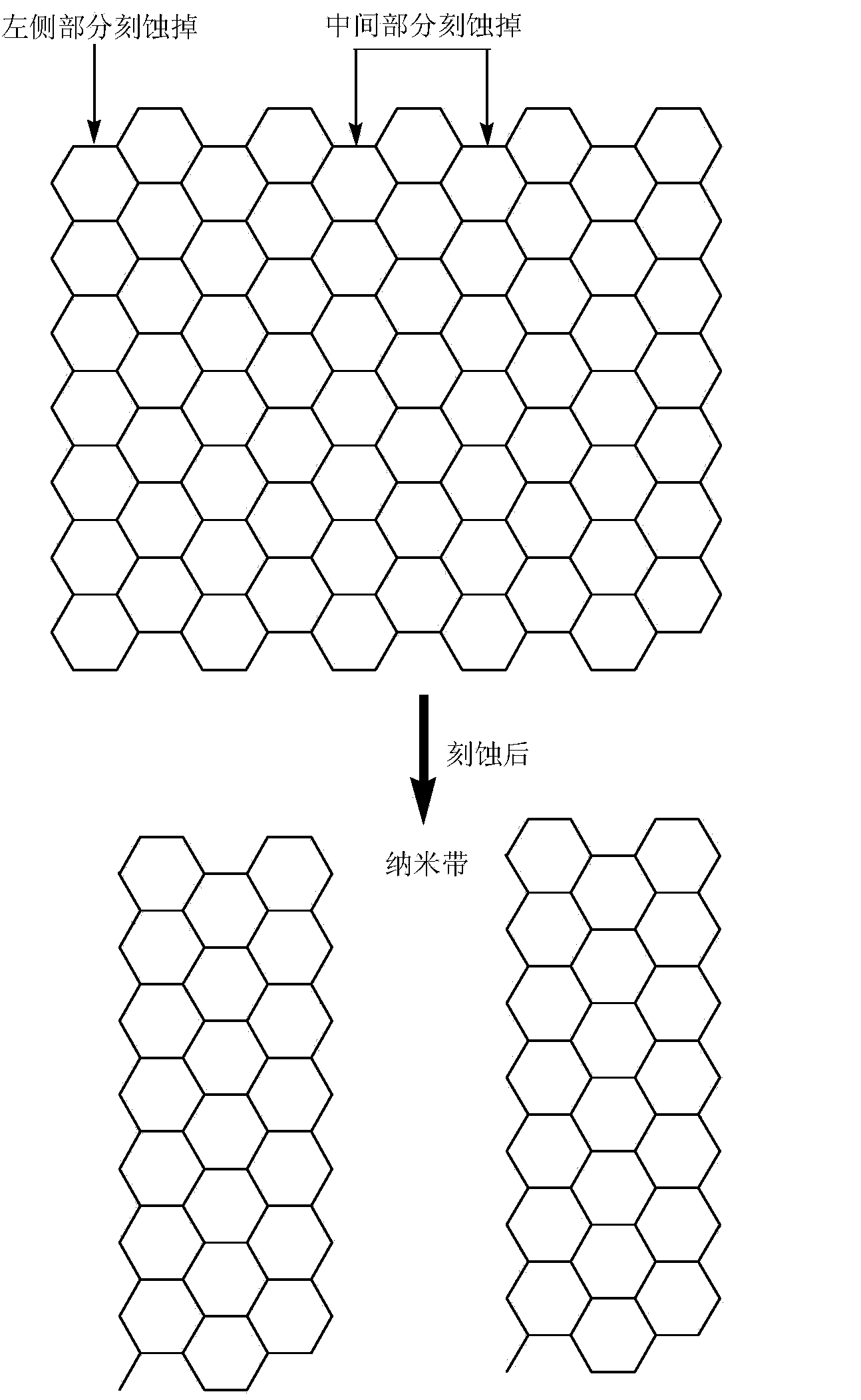

[0026] This embodiment is used for the patterning of graphene film to obtain nanoribbons, proceed as follows:

[0027] a. Spray a layer of epoxy resin with a thickness of 10 μm on the surface of the single-layer graphene sample prepared on the copper foil by electrostatic spraying, and remove the solvent in a low-temperature oven at 30°C to obtain Cu / GN / ring Oxygen resin sample A1;

[0028] b. The sample A1 is exposed on an exposure machine using two nanobelts with a width of 100 μm in the light-transmitting area of the film, and the exposed sample B1 is obtained;

[0029] c. Soak sample B1 in a sodium carbonate solution with a temperature of 25°C and a concentration of 1% for 30 minutes, remove the epoxy resin in the unexposed area, and then clean it with deionized water to obtain sample C1;

[0030] d. Place sample C1 in an oxygen plasma atmosphere, control the temperature at 60°C, and etch for 3 minutes to etch away the graphene in the area not protected by epoxy resin t...

Embodiment 2

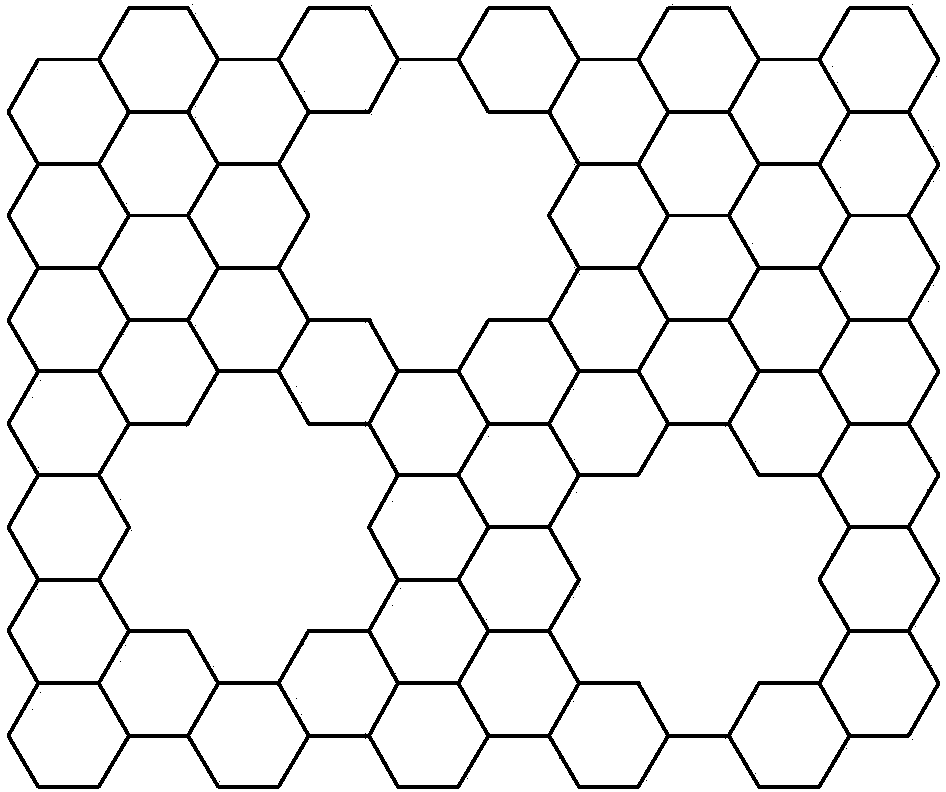

[0033] This embodiment is used for the patterning of graphene thin film to obtain flower pattern, proceed as follows:

[0034] a. Spray-print a layer of epoxy resin with a thickness of 8 μm on the surface of the single-layer graphene sample that has been prepared on the copper foil, and remove the solvent in a low-temperature oven at 30°C to obtain Cu / GN / epoxy resin sample A2;

[0035] b. Use the masked area of sample A2 as figure 2 Cover the negative film in the blank area shown, and then place it on the exposure machine for exposure to obtain the exposed sample B2;

[0036] c. Soak sample B2 in a sodium carbonate solution with a temperature of 28°C and a concentration of 1.2% for 30 minutes, remove the epoxy resin in the unexposed area, and then clean it with deionized water to obtain sample C2;

[0037] d. Place sample C2 in an oxygen plasma atmosphere, control the temperature at 70°C, and etch for 8 minutes to etch away the graphene in the area not protected by epox...

Embodiment 3

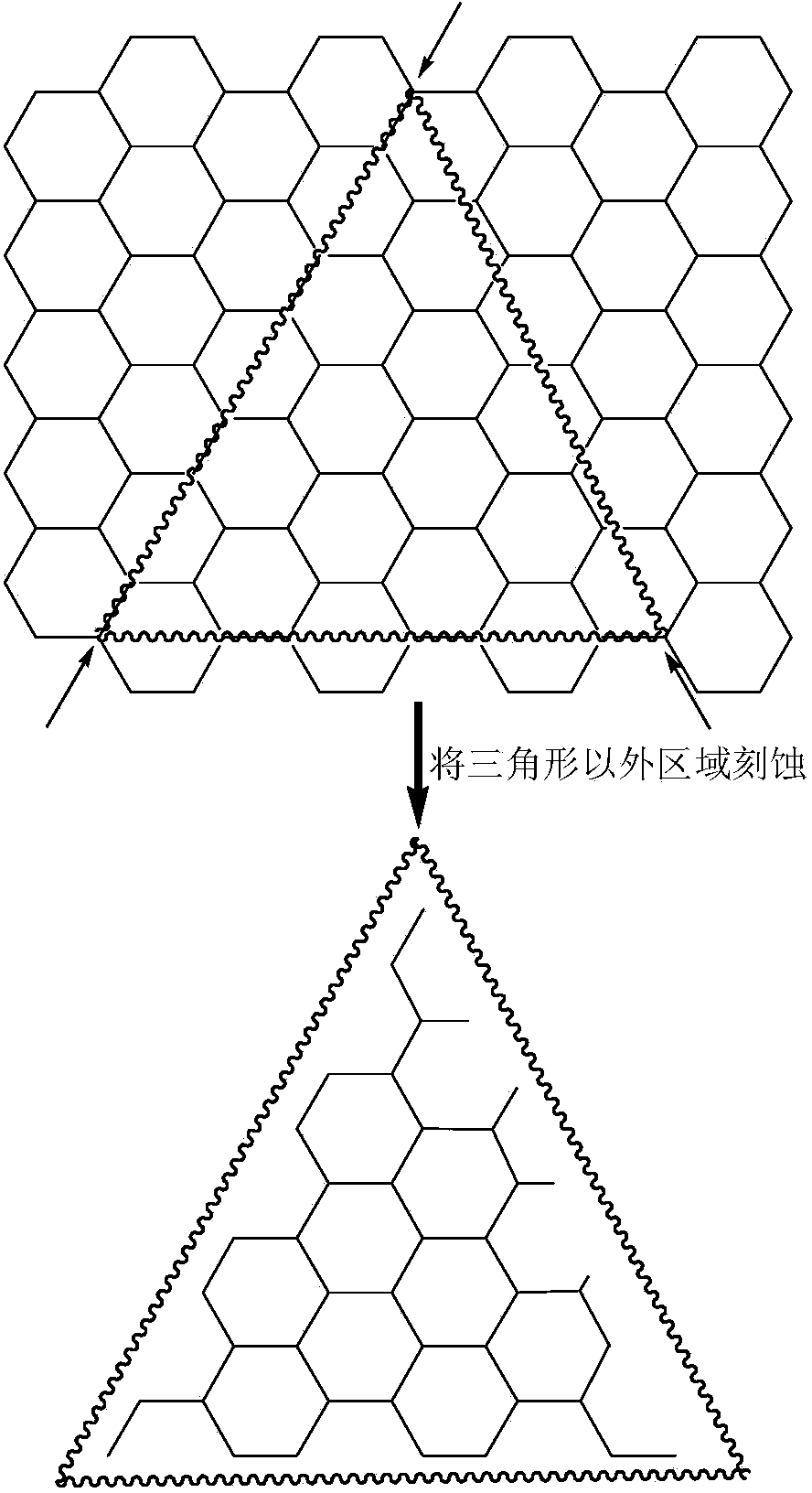

[0040] The present embodiment is used for the patterning of graphene thin film and obtains triangular pattern and carries out as follows:

[0041] a. Print a layer of epoxy resin with a thickness of 5 μm on the surface of the single-layer graphene sample prepared on the copper foil by screen printing, and remove the solvent in a low-temperature oven at 30°C to obtain Cu / GN / epoxy resin sample A3;

[0042] b. Expose sample A3 using a triangle with a side length of 200 μm in the light-transmitting area of the film, and place it on an exposure machine for exposure to obtain exposed sample B3;

[0043] c. Soak sample B3 in a sodium carbonate solution with a temperature of 30°C and a concentration of 0.8% for 25 minutes, remove the epoxy resin in the unexposed area, and then clean it with deionized water to obtain sample C3;

[0044] d. Place sample C3 in an oxygen plasma atmosphere, control the temperature at 55°C, and etch for 6 minutes to etch away the graphene in the area n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com