Method for preparing breeding feed by utilizing kitchen wastes

A technology of food waste and feed, which is applied in the field of aquaculture feed processing and the use of food waste to prepare aquaculture feed, can solve the problems of active substance loss, solvent residue, etc., increase the content of active ingredients, improve product quality, and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

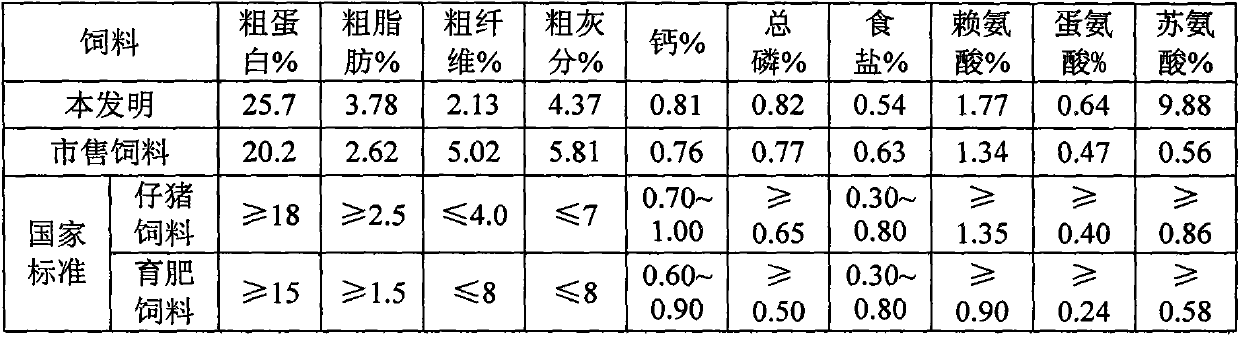

Embodiment 1

[0023] A method for preparing breeding feed using kitchen waste, comprising the following steps:

[0024] (1) Removal of impurities: Manually remove plastic, toothpicks, chopsticks, and metal impurities from the recycled kitchen waste, and set aside;

[0025] (2) Centrifugation: centrifuge the food waste after removing impurities in step (1) in a 3000r / min centrifuge for 10min;

[0026] (3) Water washing: add drinking water according to the material-to-liquid ratio of 1:2, rinse the kitchen waste in step (2), centrifuge at 3000r / min for 10min after washing, wash twice, and obtain the washed kitchen raw materials after centrifugation, for subsequent use;

[0027] (4) Squeeze: use a twin-screw squeeze dehydrator to remove the moisture in the kitchen raw materials after washing, so that the final moisture content of the material is less than 60%;

[0028] (5) High-temperature sterilization: put the squeezed material into a cooking pot and heat it to 100°C, and boil it for 25 min...

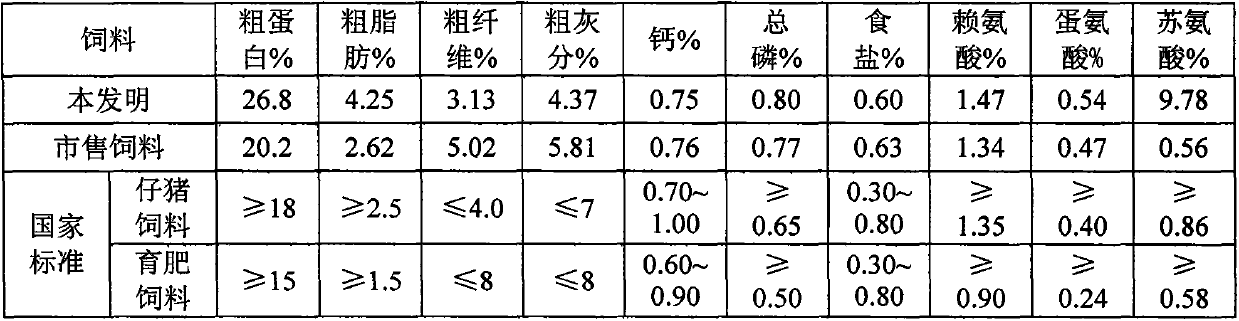

Embodiment 2

[0041] A method for preparing breeding feed using kitchen waste, comprising the following steps:

[0042] (1) Removal of impurities: Manually remove plastic, toothpicks, chopsticks, and metal impurities from the recycled kitchen waste, and set aside;

[0043] (2) Centrifugation: centrifuge the food waste after removing impurities in step (1) in a 3000r / min centrifuge for 15 minutes;

[0044](3) Water washing: add drinking water according to the material-to-liquid ratio of 1:2, rinse the kitchen waste in step (2), centrifuge at 3000r / min for 10min after washing, wash twice, and obtain the washed kitchen raw materials after centrifugation, for subsequent use;

[0045] (4) Squeeze: use a twin-screw squeeze dehydrator to remove the moisture in the kitchen raw materials after washing, so that the final moisture content of the material is less than 60%;

[0046] (5) High-temperature sterilization: put the squeezed material into a cooking pot and heat it to 100°C, and boil it for 25...

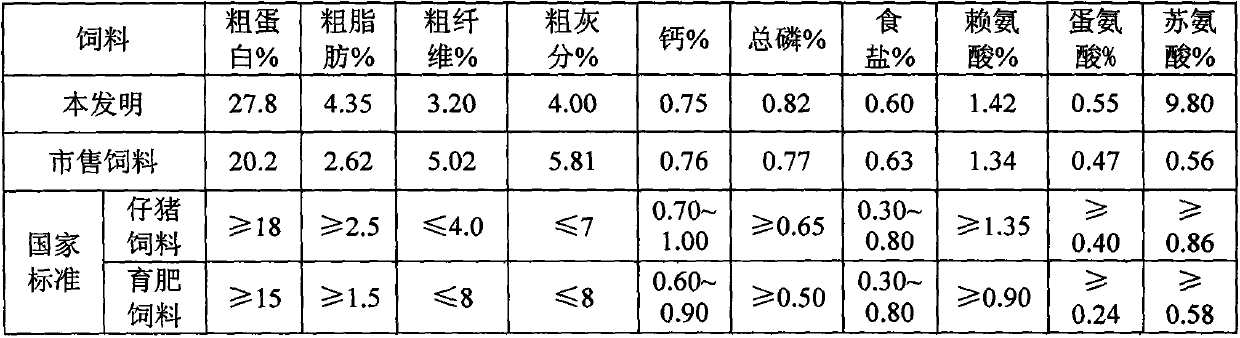

Embodiment 3

[0059] A method for preparing breeding feed using kitchen waste, comprising the following steps:

[0060] (1) Removal of impurities: Manually remove plastic, toothpicks, chopsticks, and metal impurities from the recycled kitchen waste, and set aside;

[0061] (2) Centrifugation: centrifuge the food waste after the removal of impurities in step (1) for 12 minutes in a 3000r / min centrifuge;

[0062] (3) Water washing: add drinking water according to the material-to-liquid ratio of 1:2, rinse the kitchen waste in step (2), centrifuge at 3000r / min for 10min after washing, wash twice, and obtain the washed kitchen raw materials after centrifugation, for subsequent use;

[0063] (4) Squeeze: use a twin-screw squeeze dehydrator to remove the moisture in the kitchen raw materials after washing, so that the final moisture content of the material is less than 60%;

[0064] (5) High-temperature sterilization: put the squeezed material into a cooking pot and heat it to 100°C, and boil it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com