Preparation of porous high-swelling gelatin microspheres

A technology of gelatin and microspheres, which is applied in the direction of non-active ingredients of polymer compounds, medical science, bulk transportation, etc., can solve the problems of slow drug loading and low drug loading rate, achieve the conditions, enhance the application effect, and improve The effect of drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

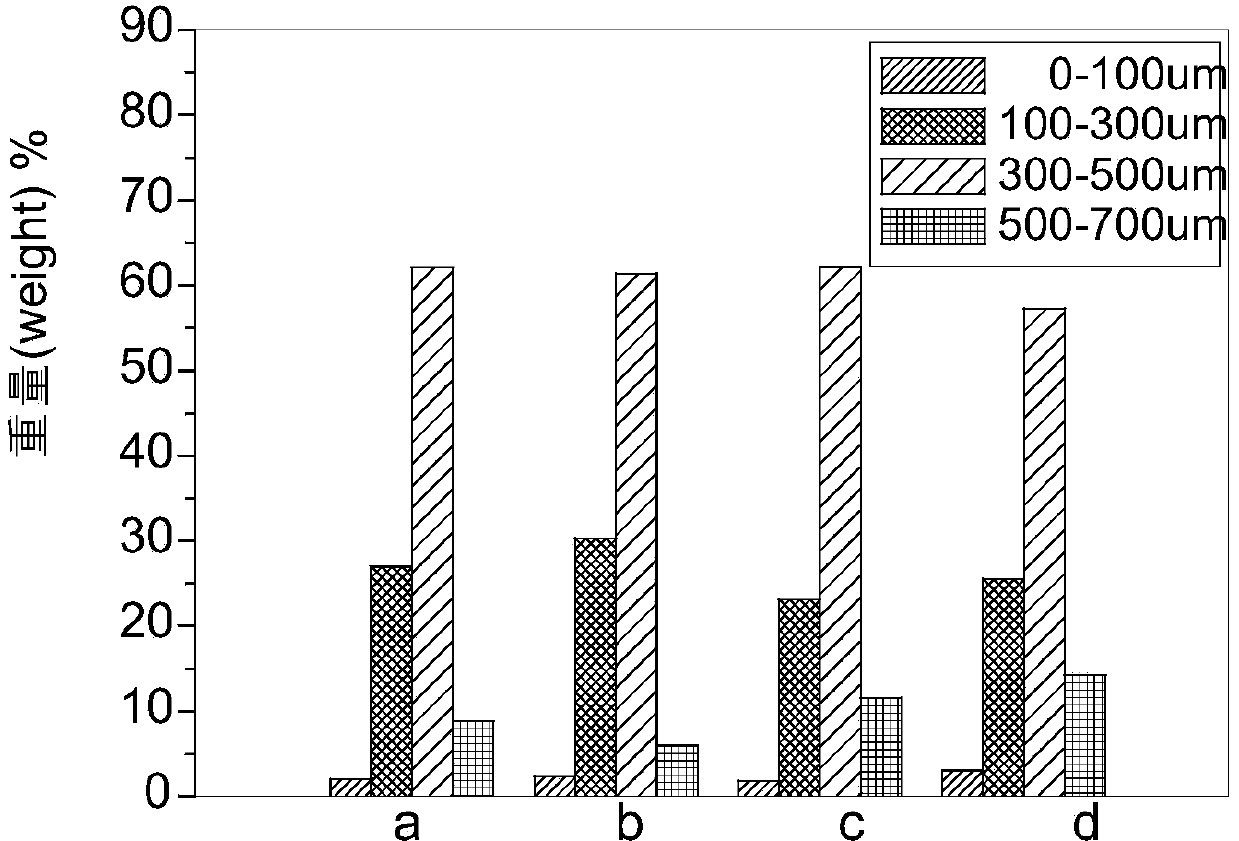

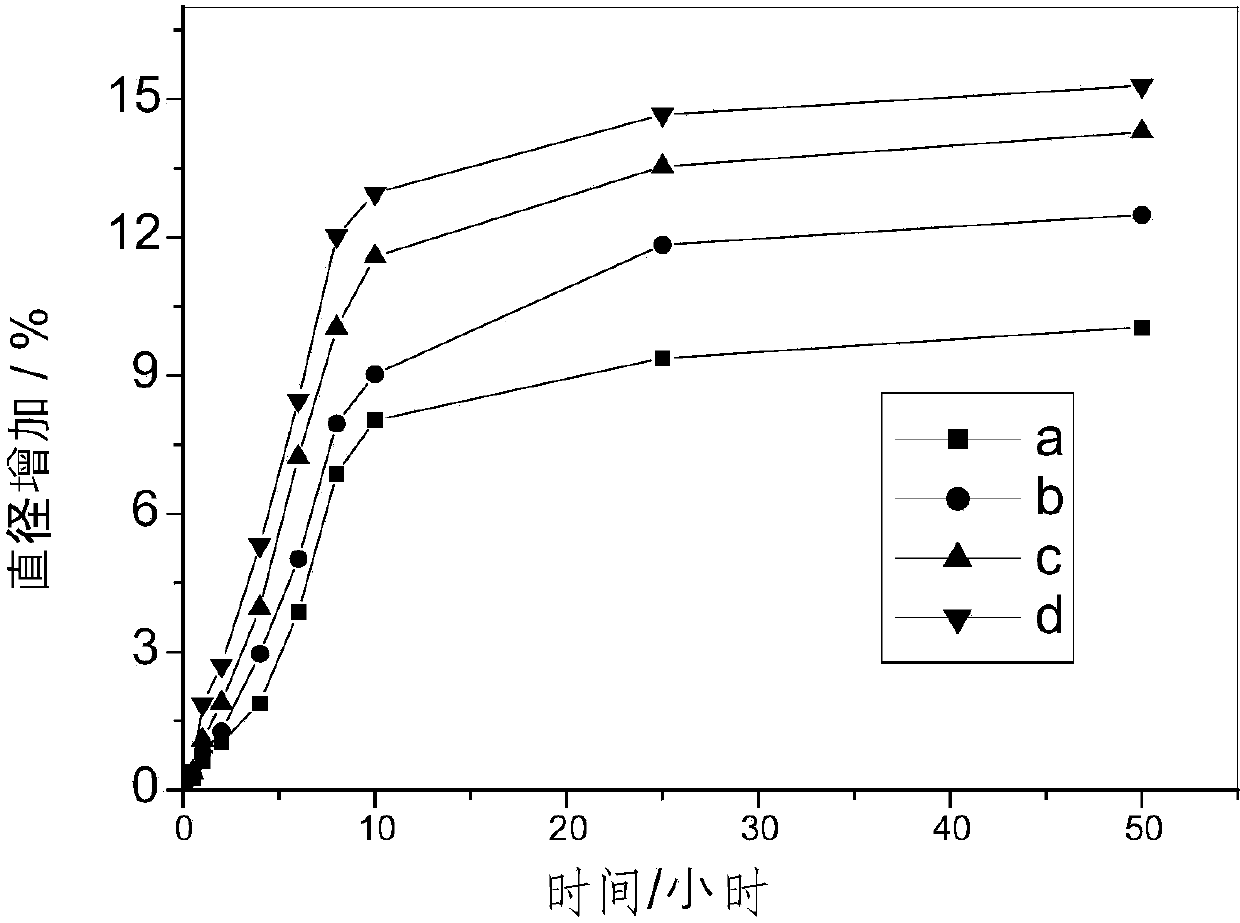

Embodiment 1

[0017] Put 50 ml of paraffin oil in a 250 ml three-neck flask, add 0.4 ml of Span-80 and 0.2 ml of Tween-60, and stir at room temperature for 10 minutes. In addition, in a 100 ml beaker, prepare 10 ml of 30% gelatin aqueous solution with distilled water, then add 1.5 grams of nano-calcium carbonate powder and mix well; pour this solution into the previously mixed paraffin oil and Span-80 and Tween- 60 dispersion, continue to stir for 1 hour, add 1M NaOH solution dropwise to adjust the pH to 8-9, slowly add 2.5 ml of 36% formaldehyde solution dropwise, react for 2 hours, filter and separate the microspheres, soak the microspheres with 15 ml of 5% acetic acid solution Stir the suspension for half an hour, filter and separate the microspheres, and repeat this cycle three times to completely dissolve and remove the calcium carbonate, filter under reduced pressure, and dry in vacuum for 48 hours to obtain light yellow gelatin microspheres.

Embodiment 2

[0019] With embodiment 1, but the weight that adds nano-calcium carbonate powder is respectively 1 gram, 2.0 gram, 2.7 gram and reacts, removes porogen again, purifies and dries.

Embodiment 3

[0021] Put 50 ml of paraffin oil in a 250 ml three-neck flask, add 0.4 ml of Span-80 and 0.2 ml of Tween-60, and stir at room temperature for 10 minutes. In addition, in a 100 ml beaker, prepare 10 ml of 30% gelatin aqueous solution with distilled water, then add 4.5 grams of PEG200 liquid and mix well; pour this solution into the well-mixed paraffin oil and Span-80 and Tween-60 Continue to stir for 1 hour, add 1M NaOH solution dropwise to adjust the pH to 8-9, slowly add 2.5 ml of 36% formaldehyde solution dropwise, react for 2 hours, filter and separate the microspheres, soak and stir the microspheres in deionized water to suspend After half an hour, the microspheres were separated by filtration, and the cyclic operation was repeated three times. The PEG200 was completely dissolved and removed, filtered under reduced pressure, and vacuum-dried for 48 hours to obtain light yellow gelatin microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com