Modified halloysite for flame-retardant polypropylene cable sheath material and preparation method thereof

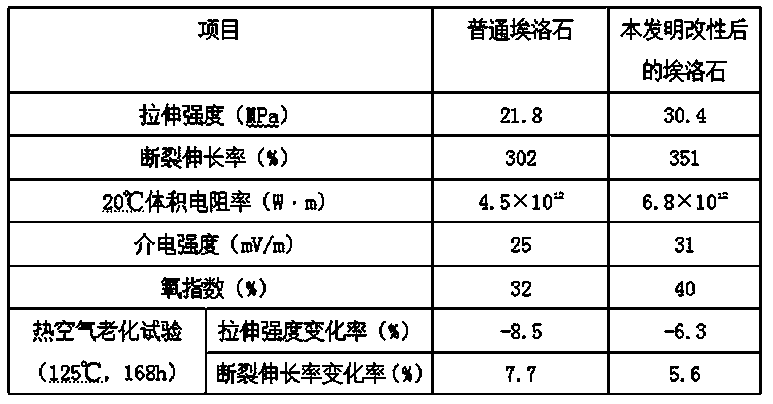

A cable sheathing material, flame retardant polypropylene technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment and other directions, can solve the problems affecting the performance of composite materials, unsatisfactory dispersion effect, poor interface bonding, etc. To achieve the effect of improving mechanical properties, superior dispersibility, and high interfacial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A modified halloysite for flame-retardant polypropylene cable sheathing material, made of the following raw materials by weight (kg): halloysite 62, ethynyl cyclohexanol 14, zinc hydroxystannate 6, triglycidyl p-aminophenol 2.5, isopropyl palmitate 3.5, yttrium naphthalate 1.5, acetyl tri-n-hexyl citrate 12, slaked lime 8, waste rubber powder 12, butylated hydroxyanisole 3, stannous pyrophosphate 2, isopropylated phosphoric acid Triphenyl ester 10, tetrabromobisphenol A-bis(2,3-dibromopropyl ether) 7, 2-hydroxy-4-methoxybenzophenone 1.5, 4,4'-dihydroxybiphenyl 1 , Auxiliary 5.5;

[0011] The additives are mixed from the following raw materials by weight (kg): neopentyl glycol diisocaprylate 4, zinc isooctanoate 2, N, N-bis(2-hydroxyethyl) alkylamine 2.5, glycerin Polyethylene oxide monostearate 1.5, tri-n-butylamine 3.5, white oil 5, lauryl mercaptan 3.5, dimer di(2-ethylhexyl) phosphate 2.5, titanium triisostearate Isopropyl ester 1.5, trimethylolpropane trio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com