Benzene-free ketone-free single-solvent printing ink and preparation method thereof

A benzene-free, ketone-free, and ink-free technology, applied in inks, household utensils, applications, etc., can solve the problems of ink dilution errors, cost losses, etc., and achieve good printing adaptability, super high expressiveness, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

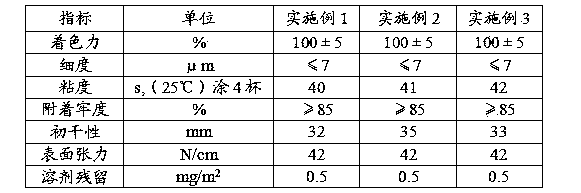

Examples

Embodiment 1

[0025] In the present embodiment, the benzene-free and ketone-free single-solvent ink of the present invention is composed of the following components by mass: 35 parts of polyurethane resin, 12 parts of ternary chlorine wax, 0.35 parts of polyethylene wax powder, and 0.8 parts of dispersant parts, 0.8 parts of anti-settling agent, 48 parts of mixed solvent, 0.6 parts of dispersant, 0.8 parts of adhesion promoter, 8 parts of defoamer and 35 parts of pigment. Among them, the polyurethane resin is a polymer of isophorone diisocyanate and polypropylene-1,2-ethylene glycol ether, and the mass percentages of the components of the mixed solvent are: n-propanol 40%, ethyl acetate 26%, isopropyl alcohol 20% propanol, 10% isobutyl acetate and 4% propylene glycol methyl ether, the adhesion promoter is modified chlorinated polypropylene, and the dispersant is polyester polyamide copolymer.

[0026] It is composed of the following components in parts by mass:

[0027] The benzene-free an...

Embodiment 2

[0034] In this embodiment, the present invention's benzo-free and ketone-free single-solvent ink is composed of the following components in parts by mass: 25 parts of polyurethane resin, 12 parts of ternary chlorine wax, 0.2 parts of polyethylene wax powder, and 0.6 parts of dispersant parts, 0.6 parts of anti-settling agent, 42 parts of mixed solvent, 0.6 parts of dispersant, 0.65 parts of adhesion promoter, 6.5 parts of defoamer and 32 parts of pigment. Among them, the polyurethane resin is a polymer of isophorone diisocyanate and polypropylene-1,2-ethylene glycol ether, and the mass percentages of the components of the mixed solvent are: n-propanol 40%, ethyl acetate 26%, isopropyl alcohol 20% propanol, 10% isobutyl acetate and 4% propylene glycol methyl ether, the adhesion promoter is modified chlorinated polypropylene, and the dispersant is polyester polyamide copolymer.

[0035] The benzene-free and ketone-free single-solvent ink with the above components is prepared int...

Embodiment 3

[0037] In the present embodiment, the present invention's benzo-free and ketone-free single-solvent ink is composed of the following components in parts by mass: 40 parts of polyurethane resin, 15 parts of ternary chlorine wax, 0.45 parts of polyethylene wax powder, and 1.0 parts of dispersant part, 1.0 part of anti-settling agent, 52 parts of mixed solvent, 0.8 part of dispersant, 1.0 part of adhesion promoter, 8.2 parts of defoamer and 38 parts of pigment. Among them, the polyurethane resin is a polymer of isophorone diisocyanate and polypropylene-1,2-ethylene glycol ether, and the mass percentages of the components of the mixed solvent are: n-propanol 40%, ethyl acetate 26%, isopropyl alcohol 20% propanol, 10% isobutyl acetate and 4% propylene glycol methyl ether, the adhesion promoter is modified chlorinated polypropylene, and the dispersant is polyester polyamide copolymer.

[0038] The benzene-free and ketone-free single-solvent ink with the above components is prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com